Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Industrial Additives Features

- Materials Features

- Benefits

- Non-phthalate plasticizer that avoids adverse perception

- High solvating plasticizer with superior plasticizing efficiency

- Compatibility in multiple polymer offering versatility in formulating

- Fast-fusing plasticizer in PVC systems to boost throughput

- Platinum P-1400 exhibits excellent permanence properties

- Features

Non-Phthalate, Fast Fuser, Excellent Processability

- Wear Layer and Foam Layer testing for the Flooring Industry

Conclusion Wear Layer testing:

Performance Series Water Absorption Carbon Volatility Clarity Low Temp. Heat Stability Heat Stability Tensile Strength DOTP + + = = = = DOTP/Santcizer Platinum P-1400 + + = = = = DOTP/Dibenzoate - - - + - + Conclusion Foam Layer testing:

Process Performance Series Fusion Foam Expansion Indentation Foam Density DOTP - = + - DOTP/Santcizer Platinum P-1400 + = + + DOTP/Dibenzoate + - - - - Detailed analysis can be found here - https://media.knowde.com/image/upload/v1614581387/production/Collateral/221692/ValtrisSanticizerPlatinumP-1400vsDBinPVCFlooringWearFoamLayer.pdf

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating End Applications

- Industrial Additives End Use

- Ink & Toner End Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Uses

Platinum P-1400 can be used in many applications including foams, sealants, calendering, plastisols, extrusion and films. Santicizer® Platinum P-1400’s primary benefits include faster fusion characteristics and high plasticizing efficiency while attaining performance properties that are similar or superior to phthalate plasticizers, but without the perceived concerns associated with phthalates.

- Santicizer® Platinum Series: P-1400, a Fast Fusing Non-Phthalate Option

As market needs and requirements change, Valtris’s commitment to providing innovative solutions for our customers remains core to our mission. Valtris has developed a new line of Non-Phthalate Plasticizers which offer excellent performance and functionality versus existing materials available in the market place. Platinum P-1400 is Valtris’s next product within the Santicizer® Platinum series, bringing a new higher efficiency, faster fusing plasticizer option to the polymer formulating world.

Santicizer P-1400’s performance and functionality benefits are:

- Faster fusing capabilities versus general-purpose plasticizers.

- Excellent plasticizer efficiency - similar to existing phthalate plasticizers.

- Highly compatible

- Processes similarly to existing general purpose phthalates

- Broad application capability including plastisol, calendering, flooring, foam, and coated seat fabric applications.

- High solvating character for better processability.

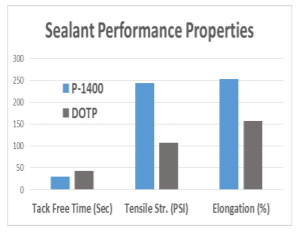

- Santicizer© Platinum P-1400 in Hybrid Sealants

Santicizer Platinum P-1400 is a non-phthalate plasticizer that is well suited for silyl-terminated polymer sealants. Hybrid sealant systems, whether polyether or polyurethane based, generally require a plasticizer to modify the performance characteristics of the cured caulk. P-1400 has shown benefits in compatibility, water resistance, skin time, and physical/mechanical properties, which can reduce cost and improve overall performance of the sealant.

Benefits:

Shorter skin times

- Reduced catalyst use

- Less dirt pick up potential

High plasticizer efficiency

- Higher filler content

- Lower plasticizer loading

Low water extraction

- Longer performance life

- Better weatherability

High compatibility

- Reduced exudation

- Improved adhesion

- DEHCH (Diethylhexyl-cyclohexane) vs. Santicizer Platinum P-1400

- DEHCH as General Purpose plasticizer competes well compared to DOTP and DINCH in both the plastisol and mill sheet formulations.

- Santicizer® Platinum P-1400 is not to be used as a General Purpose plasticizer, but tested as a General Purpose plasticizer performs just as well or better than the other general purpose plasticizers tested in both plastisol and mill sheet formulations.

pecific details about tests and elaborate conclusions can be found here - https://media.knowde.com/image/upload/v1614581333/production/Collateral/221627/ValtrisPlasticizersvsDEHCH.pdf

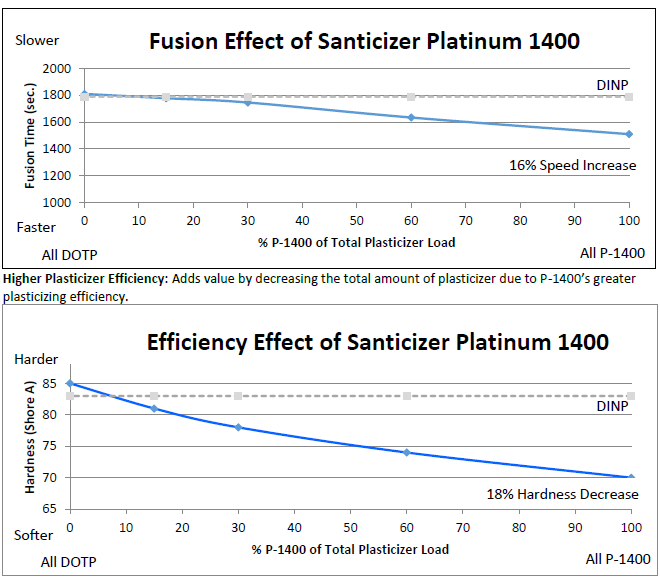

- Santicizer® Platinum P-1400, a Fusion Booster in Non-Phthalate PVC Formulations

When general purpose phthalate plasticizers, for example DINP or DOP, are replaced by alternatives such as 1,2- Cyclohexane dicarboxylic acid diisononyl ester (DINCH), 1,2-Cyclohexane dicarboxylic acid di 2-ethyl hexyl ester (DECH) or Di0-octyl terephthalate (DOTP) in PVC formulations, both the fusion time and temperature significantly increase. By adding Santicizer® Platinum P-1400 as a booster, fusion, compatibility and resistance to extraction in various environments are significantly improved.

Specific details, graphs and formulation information can be found here -

https://media.knowde.com/image/upload/v1614581370/production/Collateral/221671/ValtrisSanticizerPlatinumP-1400asfusionbooster.pdf

- Santicizer® in Lubricants Benzyl Esters as seal swell and Phosphate Esters as anti-wear additives

Santicizer® Benzyl Esters as seal swell additives

In crankcase oils, transmission oils and hydraulic fluids the lubricant is in contact with the seal. Those seals can be made of different elastomers. The generally used elastomers are:

- nitrile butadiene rubber (NBR)

- acrylic

- silicone

- fluorinated

While aging, these elastomers tend to become harder (even brittle), tend to shrink and they tend to lose their elastomeric properties (as elongation). When this aging goes along with higher temperatures, as in automotive crankcase oils, this process is even accelerated.

The loss of those elastomeric properties in an engine can be the cause of leaks and thus loss of oil. But in order not to lose the properties of the elastomers and thus prevent leakage some polar additives have to be introduced. Those have to be as compatible as possible with the different elastomers. Alkyl benzyl esters, Santicizer® 261A, Santicizer® 278, Santicizer® Platinum P-1400 & P-1700, are good compatibilizers at a low dosage of 1 to 4 wt% for different type of elastomers. In the volume change aging test according the norm CEC-L-39-T-96 the addition of a seal swell additive as a benzyl ester is necessary to avoid shrinkage of the seal when put in a pure poly alpha olefin.

Volume Change CEC-L-39-T-96 Acrylic Seal NBR Seal Time/Temperature 1 week 150ºC 1 week 100ºC Pure PAO 6 97.6 99.6 PAO 6 +2% Santicizer Benzyl Ester 100.8 106.4

Properties

- Physical Form

- Appearance

- Clear Liquid

- Typical Properties

Value Units Test Method / Conditions Color max. 40 APHA Specific Gravity (at 25°C) 1.071 - 1.078 Viscosity (at 25°C) 30 cP Moisture Content max. 0.05 % KF Hydroxyl Number 0.1 mgKOH/g - Assay Content min. 98.5 % - Valtris Santicizer® in MS Polymer Applications.

Modified silane polymers were developed 30 years ago, and we have seen a large increase in both the European and North American markets due to its great advantage of being an elastic adhesive compared to polyurethane and PVC adhesives. Modified silanes are one component adhesives which react and cure under the action of moisture, and once cured acquire elastic properties and strength of an elastomeric material. Valtris Santicizer phthalate and nonphthalate plasticizers are well suited for MS Polymer formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce Shore A Hardness.

- Improve flexibility and maintenance of mechanical properties.

- Equal tack time and cure through

- Better Water Sensitivity

Sample Viscosity (low) Shear Recovery (high) Tack Time Cure Through Shore A Migration Water Sensitivity (low % absorbed) Santicizer Platinum P-1400 ++ + = = = = + - Valtris Santicizer® in Polyurethane Applications

Polyurethane systems offer a wide variety of desirable performance features in coatings, adhesives, caulks, sealants and castable applications. Polyurethanes are used for their flexibility, excellent durability, tear resistance, and resilience. Valtris Santicizer phthalate and non-phthalate plasticizers are well suited for polyurethane applications, both 1K and 2K formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce elastic modulus and shore A hardness.

- Improve flexibility and maintain mechanical properties.

- Polar molecules, therefore, highly compatible with excellent permanence in urethane technology.

- Low Hydroxyl number and low moisture content.

- Low neat color.

- Excellent abrasion resistance

Sample Viscosity (low) Shear Recovery (high) Tack Time(fast) Cure Through(fast) Shore A Permanence Hydroxyl Number (low) Santicizer® Platinum P-1400 + + + ++ = = ++ - Valtris Santicizer® in SPUR Applications

SPUR: Silylated Polyurethanes. SPURs have a silane curing mechanism and a polyurethane backbone, but they do not contain the unreacted isocynates like standard polyurethane technology. This makes them more esthetic to the environment and they have become increasingly appealing to adhesives, sealants and coatings. SPUR formulations offer fast room-temperature cure and good durability when compared to a standard polyurethane system. Generally, a plasticizer is used in a SPUR formulation because of the need for specific properties the plasticizer can provide that the formulator is not able to reach on its own. Valtris plasticizers are compatible with SPUR technology and can offer properties not seen with standard SPUR formulations.

Benefits of using Valtris plasticizers:

- Enhance processability by modifying rheological properties.

- Reduce elastic modulus and shore A hardness.

- Improve flexibility and maintain mechanical properties.

- Offer better low temperature flexibility.

- Low Hydroxyl number and low moisture content.

- Low neat color.

Sample Viscosity (low) Shear Recovery (high) Cure Through Shore A Water Sensitivity (lower % absorbed) Permanence Cold Temperature Flexibility (lower temp) Hydroxyl Number (lower) Santicizer® Platinum P-1400 ++ ++ = = ++ = + ++ - Valtris Santicizer® in Plastisol Inks

Plastisol inks are the most commonly used products in garment printing. They are easy to print and do not dry on the screen. Plastisol inks can be used on both light and dark garments, and can adhere to most textiles. Plastisol Inks will not dry, or cure, at normal temperatures, they must be cured with heat. Plastisol inks actually bond to the fiber in the garmet instead of coloring the fiber like a dye. They are touted for having great color consistency. Plasticizers are added to the plastisol ink to give it good prinitability, water wash, and to help control bleed through, as well as many other properties.

Benefits of using Valtris plasticizers:

- Improve flexibility and mechanical properties (tensile and elongation)

- Excellent permanence attributes.

- Excellent water wash capabilities.

- Good printability, high DYNE pen surface energy

- Low bleed through

- Increased gelation and cure time

Process Performance Viscosity (lower) Gelation (faster) Fusion (faster) Water Absorption (lower % absorbed) Surface Energy (DYNE) Tensile Strength % Elongation Santicizer r Platinum P-1400 + ++ ++ - - - - - Acrylic Caulk Testing

Rhoplex A920 samples (acrylic) Santicizer® Platinum P-1400 Tack-free Time (hr:min:sec) 0:05:47 Relative Tack free time (hr:min:sec) 0:23:14 Cure-Through (days) 9 Shore A, 3-week cure at 23°C 53 Water Sensitivity

1 day water soak (% Absorbed)

28 days water soak (% Absorbed)0.41

7.23Viscosity Build (centipoise)

Initial, @ 23°C, 20 1/s

1 day, @ 23°C, 20 1/s

7 days, @ 23°C, 20 1/s

28 days, @ 23°C, 20 1/s13971

16266

14509

13398Migration of Plasticizer to Paint

Discoloration or glossiness compared to ControlNo issues

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Sealant Performance Properties

- Flagship product of the Platinum non-phthalates

- Great compatibility in many polymer systems

- PU

- PVC

- Silicone Hybrids

- Acrylics

- And more

3. High plasticizing efficiency to minimize loading levels

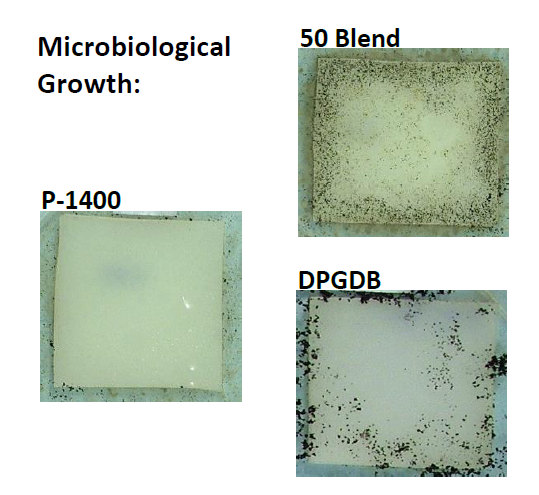

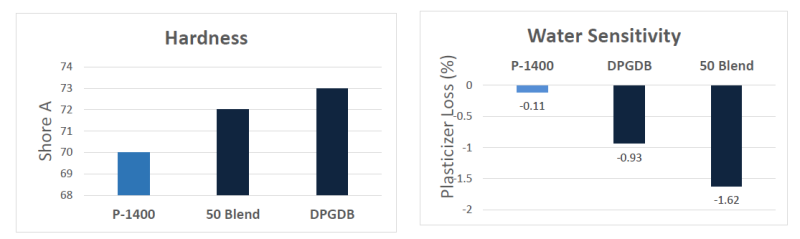

- Santicizer© Platinum P-1400 Comparison to Common Dibenzoates

Santicizer Platinum P-1400 has become a primary plasticizer choice for formulators looking for a high-solvating, non-phthalate option. In comparing specialty plasticizers P-1400 has many advantages when evaluated against other non-phthalate chemistries like dibenzoate esters. Some of these advantages can be critical when evaluating performance characteristics in applications like flooring, coatings, and other PVC plastisols.

Benefits:

- More water resistant, for longer service life

- Lower volatility, for better processing

- Reduced bio-availability, to help resist microbe growth

- Less viscosity at low temperatures, for better handling

- Better plasticizer efficiency, for lower loadings

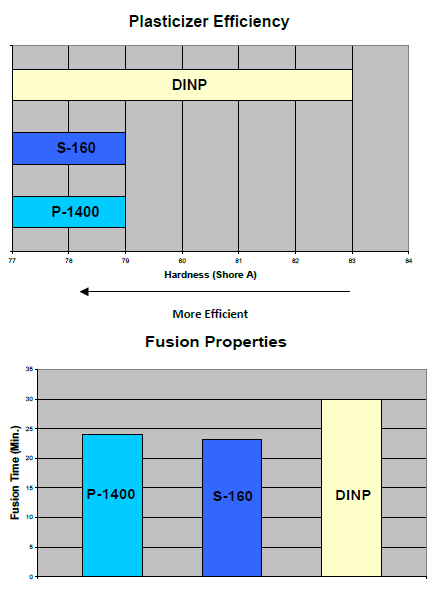

- Santicizer© Platinum P-1400, a Non-Phthalate Replacement for Santicizer© 160

With regulatory pressure on phthalates continuously increasing, and some formulators responding to consumer perceptions concerning phthalates, the need for a non-phthalate dropin replacement for existing high performance phthalate plasticizers like Santicizer© 160 is evident. Santicizer© Platinum P-1400 offers all the benefits of Santicizer© 160 without any complications associated with phthalates. Santicizer© Platinum P-1400 has been evaluated in comparison to Santicizer© 160 in multiple applications, and has been shown to be almost identical in performance and general properties.

Benefits:

Like S-160, P-1400 has:

- The same high solvating nature

- Fast fusing capabilities in PVC

- Compatibility in many polymer systems

- High plasticizer efficiency for lower plasticizer loading

- Great microbiological resistance

- High permanence and low water solubility

Comparison of Properties:

S-160 P-1400 Viscosity @25C 70 cP 30 cP Spec. Grav. 1.12 1.04 Volatility 2.3% 2.2% Color (APHA) 30* 40* Moisture 0.15%* 0.15%* Solubility (Small’s) 9.88 9.64 Comparative Performance (in PVC): S-160 P-1400 Fusion Time (min:sec) 23:07 23:58 Plasticizer Efficiency (Hardness: Shore A) 69 69 Water Sensitivity (plasticizer loss) 0.10% 0.11% Tensile Strength (PSI) 323 331 Mixed Viscosity (cP) 4500 3125 Visocsity Rise (cP @ 1 day) 2275 2375 - Santicizer® Platinum P-1400 use in Acrylic Caulk.

Santicizer Platinum P-1400 is a non-phthalate plasticizer that is well suited for waterbase acrylic caulk formulations. Acrylic caulk formulations generally require a plasticizer to modify their performance characteristics of the cured material. Santicizer Platinum P-1400 shows performance benefits in Viscosity Stability, Tack Free Time, Cure Through, and Efficiency when compared to benzoate technology.

Viscosity Stability

- Lower initial viscosity and lower viscosity over time.

- No need for viscosity reducers

Faster Tack Free Time

- Less dirt pick-up.

Faster Cure Through Time

- DIY Projects can be completed faster.

- More easily paintable.

High Plasticizer Efficiency

- Higher filler content for decreased cost.

- Lower plasticizer level for decreased cost.

Testing Santicizer® Platinum P1400 Benzoate Viscosity Build (centipoise) Initial, @ 23°C, 20 1/s 14877 22842 1 day. 23°C, 20 1/s 13821 23199 7 days. @ 23°C, 20 1/s 14302 28479 28 days. @ 23°C, 20 1/s 16717 32432 Tack-free Time (hr: min:sec) 0:06:01 0:08:13 Cure-Through (days) 9 10 Shore A, 3-week cure at 23°C 48 54 - Santicizer© Platinum P-1400 in Non-Phthalate Blending

Santicizer© Platinum P-1400 is a non-phthalate, high solvating, primary plasticizer with compatibility in many polymers systems and fast fusion characteristics in PVC. By blending P-1400 with non-phthalate general purpose plasticizers, a balance of performance characteristics and cost effectiveness can be achieved. P1400 is compatible with plasticizers currently offered in the market, so blending with P-1400 can give formulators flexibility in reaching product requirements.

Quicker fusion speeds or lower required energy: Translates to increased lines speeds/cycle times, more product throughput, and shorter oven residence times or lower energy costs from decreased oven temperatures.

Packaging & Availability

- Country Availability

- Regional Availability