Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- Materials Features

- Benefits

- An active fire suppressant replacing other plasticizers which may act as fuels

- Compatibility in many polymer systems offers versatility

- Reduces smoke emissions during combustion

- Fast-fusing plasticizer in PVC systems to boost throughput

- Non-halogenated to avoid regulation and adverse perception

- Low volatility to maintain plasticizer presence during heat or vacuum processing

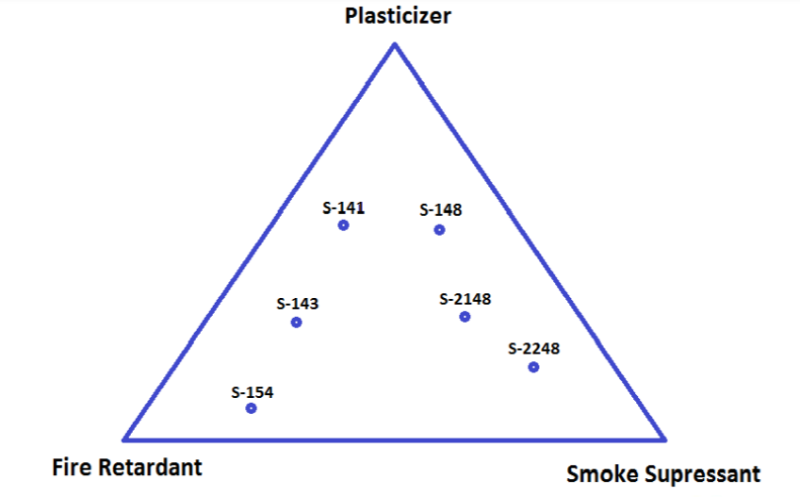

- Comparative Product Properties of Santicizer® Phosphate Ester, Fire Retardant Plasticizers

Valtris offers a family of non-halogenated, phosphate ester, fire retardant plasticizers that formulators can utilize to add specific performance benefits to products in order to meet smoke and flame testing requirements for their applications. These products offer the dual benefits of fire retardant chemical interactions, and the replacement of traditional plasticizers which act as fuels.

Fire Retardant Smoke Suppressant Plasticizer Phosphorous Content Santicizer® 148 + +++ +++ 7.9%

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Ink & Toner Type

- Plastics & Elastomers End Uses

- Uses

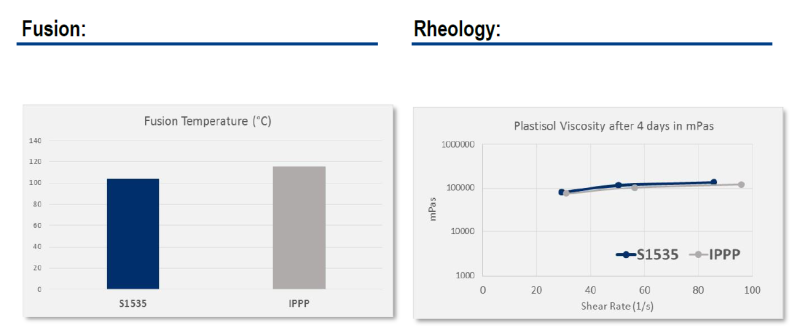

Santicizer®148 helps to suppress smoke during combustion of materials it is used in. Santicizer®148’s non-halogen nature avoids adverse perceptions of halogenated fire retardants. In PVC, Santicizer® 148 acts as a high solvating plasticizer, offering permanence, faster fusion and high plasticizing efficiency. Santicizer® 148, all with lower volatility than Santicizer® 141 to help plasticizer retention during processing.

- Santicizer® in Lubricants Benzyl Esters as seal swell and Phosphate Esters as anti-wear additives

Santicizer® Benzyl Esters as seal swell additives

In crankcase oils, transmission oils and hydraulic fluids the lubricant is in contact with the seal. Those seals can be made of different elastomers. The generally used elastomers are:

- nitrile butadiene rubber (NBR)

- acrylic

- silicone

- fluorinated

While aging, these elastomers tend to become harder (even brittle), tend to shrink and they tend to lose their elastomeric properties (as elongation). When this aging goes along with higher temperatures, as in automotive crankcase oils, this process is even accelerated.

The loss of those elastomeric properties in an engine can be the cause of leaks and thus loss of oil. But in order not to lose the properties of the elastomers and thus prevent leakage some polar additives have to be introduced. Those have to be as compatible as possible with the different elastomers. Alkyl benzyl esters, Santicizer® 261A, Santicizer® 278, Santicizer® Platinum P-1400 & P-1700, are good compatibilizers at a low dosage of 1 to 4 wt% for different type of elastomers. In the volume change aging test according the norm CEC-L-39-T-96 the addition of a seal swell additive as a benzyl ester is necessary to avoid shrinkage of the seal when put in a pure poly alpha olefin.

Volume Change CEC-L-39-T-96 Acrylic Seal NBR Seal Time/Temperature 1 week 150ºC 1 week 100ºC Pure PAO 6 97.6 99.6 PAO 6 +2% Santicizer Benzyl Ester 100.8 106.4 Santicizer® Phosphate Estes as anti-wear additives:

In general lubrication applications as hydraulic fluids and gearboxes and in metal cutting and forming lubricants anti-wear additives are used. Santicizer® 148, which is a non-classified alkyl aryl phosphate ester, is an excellent anti wear additive

Iso 46 Mineral Oil + Santicizer® 148 as anti-wear Iso 46 Mineral Oil 1% 2% No anti-wear ASTM D4172 wear (mm) 0.42 0.45 1.30

Properties

- Physical Form

- Appearance

- Clear Liquid

- Typical Cast Resin Properties - Fully Postcured Castings

Value Units Test Method / Conditions Phosphorus Content 7.83 % - Typical Properties

Value Units Test Method / Conditions Acidity max. 0.20 meq/g Color max. 100 APHA Moisture Content max. 0.10 % KF Specific Gravity (at 25°C) 1.057-1.067 Viscosity (at 25°C) 22.5 cP - Santicizer® 148 in flame retarded low smoke PVC Flooring for Building and Transit applications

Santicizer® 148 is an excellent plasticizer for low smoke and flame retarded flooring applications. Hereunder an example on how this plasticizer can be used in this application.

Impregnation Top Coat E PVC K70 75 75 Extender PVC K64 25 25 Santicizer® 148 67 38 Vicodepressant 8 CaCO3 145 11 ZnO 2.3 Lankromark LZB 578 2 2.8

Regulatory & Compliance

Technical Details & Test Data

- Test Data

Packaging & Availability

- Country Availability

- Regional Availability