Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- Industrial Additives Functions

- CAS No.

- 90076-65-6

- EC No.

- 618-438-1

- Technologies

- Product Families

- Components

Polymer - Composite Material with Lithium Salt

Features & Benefits

- Industrial Additives Features

- Product Highlights

Electrolyte Materials for All Solid State Batteries

A long trusted source for custom developed materials used in lithium ion batteries, NEI Corporation is your go to source for commercial and custom solid electrolyte materials. Solid electrolytes conduct lithium ions at room temperature and can potentially replace conventional organic electrolytes, which are flammable and toxic, thereby drastically improving the safety of batteries. NEI is actively involved in producing different solid electrolyte materials of both oxide and sulfide based compositions, as well as polymer based electrolyte materials.

Applications & Uses

- Markets

- Applications

- Battery Type

- Industrial Additives End Use

Properties

- Physical Form

- Soluble in

- Common polar organic solvents

- Physical Properties

Value Units Test Method / Conditions Crystallinity Amorphous - - - Technical Data

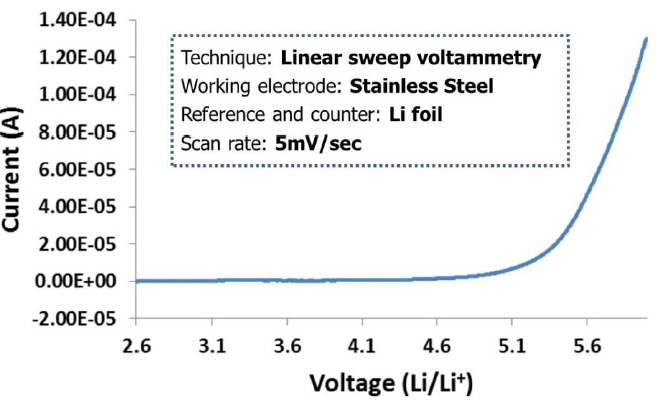

Value Units Test Method / Conditions Capacity (at 0.04C, with LiFePO₄) min. 150 mAh/g - Capacity (at 0.04C, with NMC₈₁₁) min. 190 mAh/g - Glass Transition Temperature (DSC) max. - 40 °C - Interfacial Resistance with Li 170 ohms/cm² - Ionic Conductivity (at Room Temperature) 2⁻⁴ x 10⁻⁴ S/cm - Stability Window (vs. Li/Li+) max. 5.2 V - Stable Temperature Range max. 150 °C -

Technical Details & Test Data

- Voltage Stability

- Processing Instructions

NANOMYTE® SE-50 solid electrolyte can be cast directly onto a cathode tape for cell assembly. (*Note: It is important to protect the material from moisture. SE-50 can be handled in a dry room for short periods of time. See Storage & Handling for more details.*) If freestanding membranes are desired, NANOMYTE H-polymer is recommended (H-polymer has slightly lower ionic conductivity compared to SE-50).

Cell Preparation :

When fabricating cells, NANOMYTE® SE-50 is incorporated into the electrode tape in order to confer ionic conductivity to the electrode. This is in contrast to cells using a liquid electrolyte, where the liquid electrolyte molecules can get access to the pores in the electrode. When used in conjunction with traditional binders, such as PVDF, SE-50 serves as a conductive binder to afford Li+ conductivity in the electrodes and reduce the interfacial resistance between the cathode and electrolyte. An example cathode composition comprises of 70% cathode material (by weight), 15% NANOMYTE® SE-50, 10% carbon black, and 5% PVDF.

After the cathode containing NANOMYTE® SE-50 is fabricated, the solid electrolyte can then be cast directly onto the cathode tape. For this purpose, make a solution of SE-50 in acetonitrile (e.g., 30 wt%) and cast it onto the electrode tape. Let the solvent dry in argon or nitrogen atmosphere (or a dry room) until the coating appears dry, and then transfer to vacuum drying at 60 °C for 2 hours. The cathode and separator layers can then be combined with the anode to complete cell assembly.

Packaging & Availability

- Packaging Type

- Packaging and Quantities

NANOMYTE® SE-50 is a bulk solid and is offered in lots of 10g, 25g, 50g, & 100g (or larger) quantities

Storage & Handling

- Storage and Handling

Precautions for Safe Handling

Material is hygroscopic – protect from moisture and humidity. Handle in a controlled environment, preferably in a glovebox under inert gas. Material may also be handled in a dry room for a few hours at a time. Appropriate personal protective equipment should be used at all times. Avoid contact with eyes, skin, and clothing. Provide appropriate exhaust ventilation and avoid inhalation of dust, vapors, or mist.

If product is dispersed in solvent, keep away from sources of ignition – no smoking. Take measures to prevent the buildup of electrostatic charge. For additional precautions, see Safety Data Sheets.

Conditions for Safe Storage

Best stored under inert gas. Keep container tightly sealed, in a cool, dry, and well-ventilated place. This material is moisture sensitive. Protect from humidity and keep away from water. Keep away from oxidizing agents. Store in a locked cabinet or with access restricted to technical experts or their assistants. If product is dispersed in solvent, be sure that opened containers are carefully resealed and kept upright to prevent leakage.