Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Attributes

- Secondary moisture cure for shadowed areas

- Low viscosity, works well with automated dispense equipment

- Maintains high fluorescence after curing

- Key Attributes

- Clear, thin, flexible, and durable

- Protects against dust, humidity, salt spray, corrosion, and chemical fogs

- Protects against electrical arching, shorts, static discharges, and thermal shocks

- Contains a UV indicator for optical inspection

- Applied by brushing, dipping, manual and selective spraying

- Available in liquid, aerosol, and pen

- IPC and UL certified versions

- Brush

- 4200UV can be applied by brush for rework or touch-ups. Thinning is not required for most brush applications. Desired coating thickness can be achieved in a single application. Applied coating can be cured immediately.

Applications & Uses

- Application Method

- Cure Method

- Applications

- Improves reliability, and lengthens the life of electronic circuitry

- Protects circuitry in coastal, tropical, marine, and other humid environments

- Allows electronic devices to operate in harsh environments

- Allows traces to be placed closer together by preventing arcing

- Manual Spray Guns

4200UV can be readily sprayed using conventional spray guns. Ensure air lines are dry to prevent any premature curing. Use a standard fluid nozzle gun with a minimum tip diameter of 0.8–1.0 mm. The settings listed below are recommendations; however, performance will vary with different brands:

Inlet Air flow Air cap 20–40 psi 10–15 SCFM 8–10 psi - Recommended Preparation

- Clean the substrate with Isopropyl Alcohol, MG #824, so the surface is free of oils, dust, and other residues.

Properties

- Typical Properties

Value Units Test Method / Conditions Theoretical Coverage at 50 mm 186 900 cm2/L - Storage Temperature Range 4-40 °C - Recommended Film Thickness 50-125 μm - - Cured Properties

Value Units Test Method / Conditions Glass Transition Temperature (Tg) 72 °C - Service Temperature Range -65 to 150 °C - Resistivity 3.4 x 10⁽¹⁴⁾ Ω·cm - Dielectric Strength 1 000 V/mil - CTE (Prior Tg) 78 ppm/˚C - Insulation Resistance 1 x 10⁽¹³⁾ Ω - Dielectric Withstand Voltage min. 1500 V - CTE (After Tg) 213 ppm/˚C - - Uncured Properties

Value Units Test Method / Conditions Density 1.06 g/mL - Calculated VOC 585 g/L - Percent Solids 96 % - Viscosity (at 25˚C) 160 cP - - Selective Coating

The settings listed below are recommendations and performance will vary with different brands.

Settings PVA Nordson Asymtek Valve FCS300-ES SC-350 Air Pressure 1.5 psi 4 psi Fluid Pressure 20 psi 5 psi Dispense Height 10 mm 13 mm Pass Width 4 mm 2.5 mm Coating Speed 100 mm/s 559 mm/s

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Certified

IPC-CC-830C and UL746E

- Certified

- Certified UL746E

- Certified IPC-CC-830C

Technical Details & Test Data

- Dip Coat

Due to the dual curing nature of this coating, it is important to control exposure to light and moisture to prevent premature curing.

- Hang the PCB on a dipping arm.

- Slowly lower the PCB into a tank and leave immersed in the coating for 2 min to allow penetration.

- Slowly withdraw the PCB from the tank at a rate of approximately 6" per minute.

- Applied coating can be cured immediately.

- Cured Setting

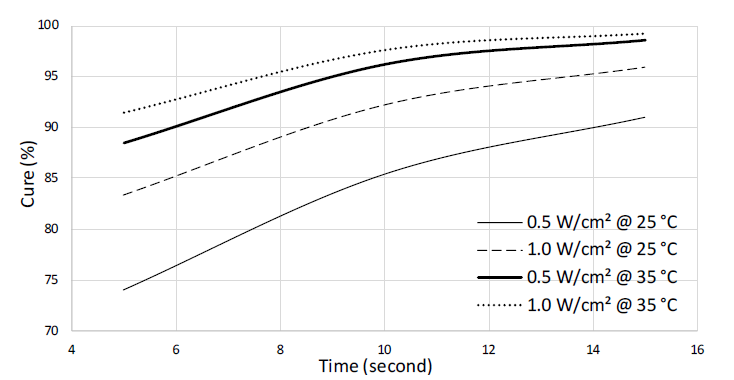

The cure settings for 4200UV depends on using the correct UV light intensity at the correct wavelength bandwidth along with other variables like temperature and humidity. To achieve a tack-free surface, expose the coating to the dosages outlined in the table below. Increasing the temperature will accelerate curing and subsequently lower the required UV exposure as can be seen in the graph below. The cure behavior of 4200UV was tested between 320-500nm covering both the UVA and UVB bands and has been designed for use with standard ‘H’ or ‘H+’ type bulbs. 4200UV contains a secondary moisture cure mechanism which will cure any shadowed areas within 24 hours at ambient moisture.

Temperature Irradiance Dose 25 °C Min. 0.5 W/cm2 3.6 J/cm2 Max. 1.0 W/cm2 3.6 J/cm2 35 °C Min. 0.5 W/cm2 0.99 J/cm2 Max. 1.0 W/cm2 0.97 J/cm2

Packaging & Availability

- Packaging Type

- Available Packaging

Cat. No. Packaging Net Volume Net Weight 4200UV-945ML Can 945 mL 1.00 kg 4200UV-3.78L Can 3.78 L 4.02 kg

Storage & Handling

- Shelf Life

- 1 Year

- Storage and Handling

- Store between 4 and 40 ˚C in a in a dry area, away from sunlight (see SDS).