Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Attributes

- VESTAMID® L2124 NC is characterized by a high melt viscosity and good dimensional control during pipe extrusion.

- Properties of compounds based on PA12 vary little with changing humidity due to low moisture absorption. Parts made of this semi- crystalline material are characterized by exceptional impact strength, low coefficient of friction and good chemical resistance. Pigmentation may affect values.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color (Properties)

- Flame Rating

- Physical Form

- Mechanical Properties

Value Units Test Method / Conditions Tensile Modulus (dry) 58000 psi ISO 527 Tensile Modulus (cond.) 50800 psi ISO 527 Tensile Strength (dry) 3770 psi ISO 527 Yield Stress (dry) 3770 psi ISO 527 Yield Stress (cond.) 3190 psi ISO 527 Yield Strain (dry) 31 % ISO 527 Yield Strain (cond.) 27 % ISO 527 Stress at 50% Strain (dry) 3920 psi ISO 527 Stress at Break (dry) 5660 psi ISO 527 Nominal Strain at Break (ɛtb, dry) 200 % ISO 527 Nominal Strain at Break (ɛtb, cond.) min. 50 % ISO 527 Tensile Creep Modulus (0.5% Strain, 1h, cond.) 50800 psi ISO 899-1 Tensile Creep Modulus (0.5% Strain, 1000h, cond.) 39200 psi ISO 899-1 Charpy Notched Impact Strength (+23°C, dry) 66.6 ftlb/in² ISO 179/1eA Charpy Notched Impact Strength (-30°C, dry) 2.85 ftlb/in² ISO 179/1eA Charpy Notched Impact Strength (-30°C, cond.) 2.85 ftlb/in² ISO 179/1eA Flexural Modulus (23°C, dry) 58000 psi ISO 178 Flexural Stress at Conv. Deflection (23°C, dry) 2030 psi ISO 178 Flexural Strength (23°C, dry) 3050 psi ISO 178 Flexural Strain at Flexural Strength (23°C, dry) 9 % ISO 178 - Physical Properties

Value Units Test Method / Conditions Density (dry) 1.03 g/cm³ 1SO 1183 Density (cond.) 1.04 g/cm³ 1SO 1183 Water Absorption (dry) 1.3 % Sim. to 1SO 62 Humidity Absorption (dry) 0.5 % Sim. to 1SO 62 - Thermal Properties

Value Units Test Method / Conditions Melting Temperature (dry) 336 °F ISO 11357-1/-3 Temperature of Deflection Under Load A (1.80 Mpa, dry) 113 °F ISO 75-1/-2 Temperature of Deflection Under Load B (0.45 Mpa, dry) 208 °F ISO 75-1/-2 Vicat Softening Temperature A (10 N, 50 K/h, dry) 327 °F ISO 306 Vicat Softening Temperature B (50 N, 50 K/h, dry) 257 °F ISO 306 Coefficient of Linear Thermal Expansion (23°C to 55 °C, Parallel, dry) 0.0001 in/in/°F ISO 11359-1/-2 Coefficient of Linear Thermal Expansion (23°C to 55 °C, Normal, dry) 9.44e-05 in/in/°F ISO 11359-1/-2 - Electrical Properties

Value Units Test Method / Conditions Volume Resistivity (pV, dry) 1E10 Ohm*m IEC 62631-3-1 Volume Resistivity (pV, cond.) 2E9 Ohm*m IEC 62631-3-1 Surface Resistivity (σE, cond.) 1E12 Ohm IEC 62631-3-2 Relative Permittivity (100Hz, dry) 12 - IEC 62631-2-1 Relative Permittivity (100Hz, cond.) 16 - IEC 62631-2-1 Relative Permittivity (1MHz, dry) 3.8 - IEC 62631-2-1 Relative Permittivity (1MHz, cond.) 4.2 - IEC 62631-2-1 Dissipation Factor (100Hz, dry) 1600 E-4 IEC 62631-2-1 Dissipation Factor (100Hz, cond.) 1600 E-4 IEC 62631-2-1 Dissipation Factor (1Mhz, dry) 1500 E-4 IEC 62631-2-1 Dissipation Factor (1Mhz, cond.) 2000 E-4 IEC 62631-2-1 Electric Strength (AC, S20/S20, t. 1 mm, dry.) 813 kV/in IEC 60243-1 Electric Strength (AC, S20/S20, t. 1 mm, cond.) 686 kV/in IEC 60243-1 Comparative Tracking Index (Test Solution A, 50 Drops Value, dry) 600 - IEC 60112 Comparative Tracking Index (Test Solution A, 50 Drops Value, cond.) 600 - IEC 60112 - Rheological Calculation Properties

Value Units Test Method / Conditions Minimum Mold Temperature 86 °F - Maximum Mold Temperature 212 °F - Minimum Melt Temperature 392 °F - Maximum Melt Temperature 464 °F - - Test Specimen Production

Value Units Test Method / Conditions Injection Molding - Melt Temperature 428 °F ISO 294 Injection Molding - Mold Temperature 140 °F ISO 294 Injection Molding - Injection Velocity 7.87 in/s ISO 294 Injection Molding - Pressure at Hold 10200 psi ISO 294 - Rheological Properties

Value Units Test Method / Conditions Melt Volume Flow Rate (dry, at 527°F, 11lb) 18.8 cm³/10min ISO 1133 Molding Shrinkage (Parallel, dry) 0.7 % ISO 294-4, 2577 Molding Shrinkage (Normal, dry) 1.6 % ISO 294-4, 2577 Mold Temperature (dry) 176 °F - Melt Temperature (dry) 464 °F - - Burn Testing Properties

Value Units Test Method / Conditions Burning Behavior (at 1.5 mm Nominal Thickness) (dry) HB class IEC 60695-11-10 Burning Behavior (at Thickness 0.1260 in.) (dry) HB class IEC 60695-11-10

Technical Details & Test Data

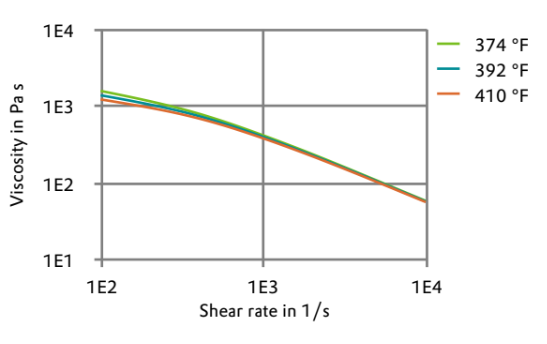

- Viscosity - Shear Rate HKR

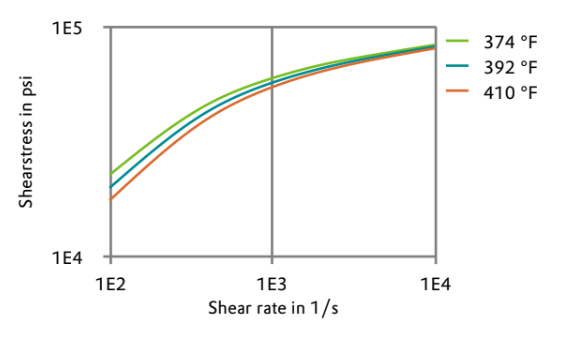

- Shearstress - Shear Rate HKR

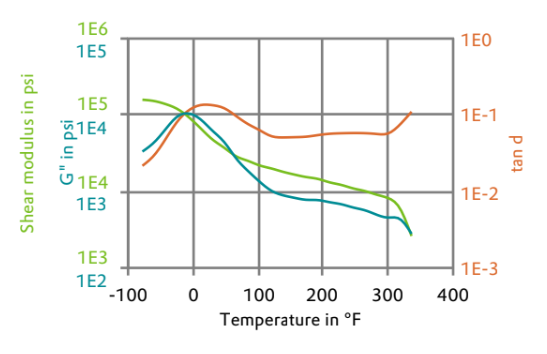

- Dynamic Shear Modulus - Temperature (Dry)

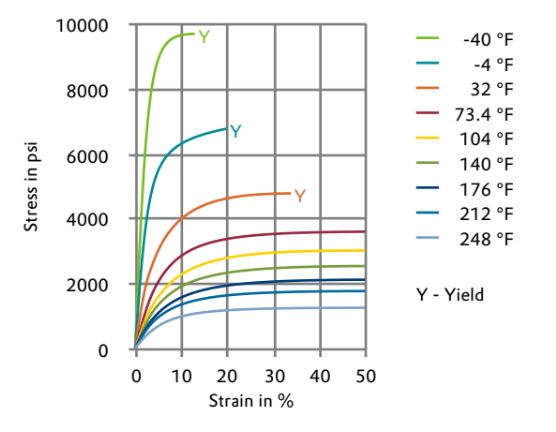

- Stress - Strain (Dry)

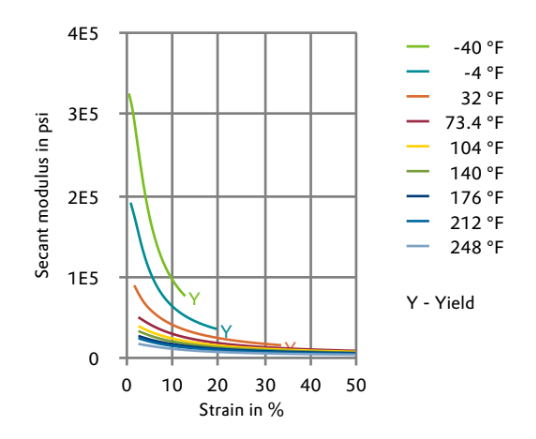

- Secant Modulus - Strain (Dry)

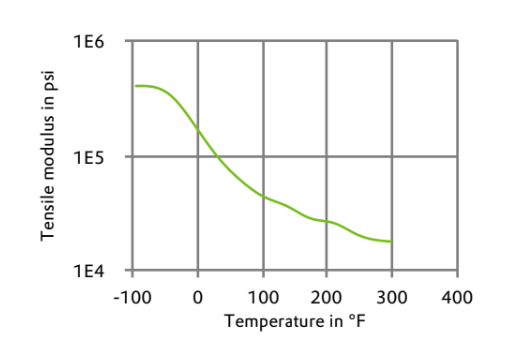

- Tensile Modulus - Temperature (Dry)

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

Inside the original and undamaged packaging, the product has a shelf life of at least 2 years when stored in dry rooms at temperatures not exceeding 30°C.