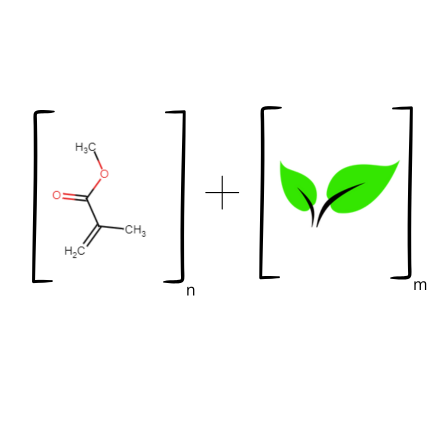

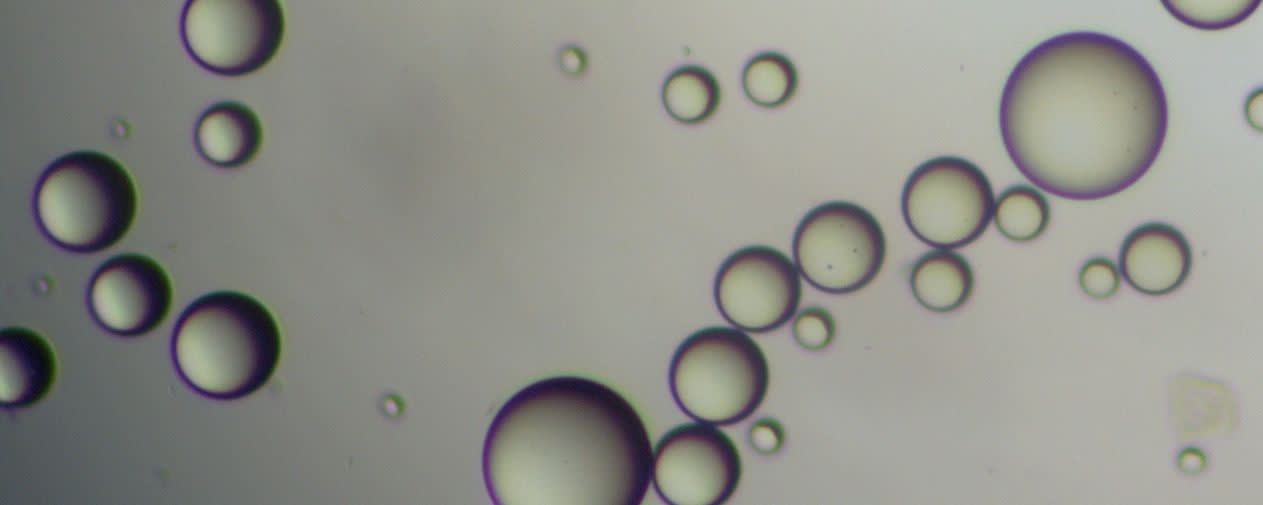

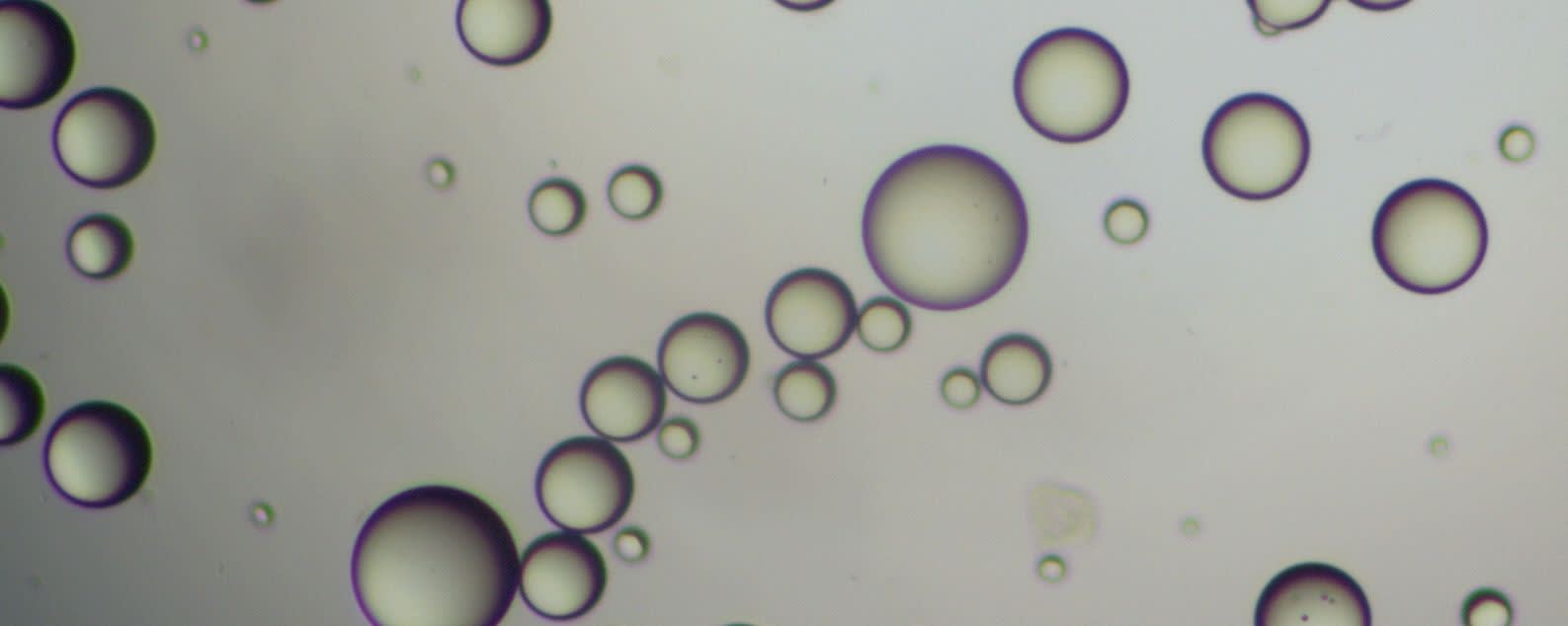

Methyl methacrylate (MMA) bead polymers are known for high glass transition temperature, melting point, tensile strength, and impact strength.

Applications: Chemical Manufacturing, Glazing & Window Elements, Siding & Trim, Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Additive Manufacturing, Textile Manufacturing, Carpet & Upholstery, Apparel, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Building Materials, Parts & Components, Medical, Chemical & Industrial Manufacturing, Packaging Coatings, Beauty & Care, Building Envelope & Roofing, Decorative Materials & Finishes, Leather & Textiles

Product Families: Cement & Concrete Additives, Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Binders, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Construction Chemicals, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Methacrylates, Acrylic Ester Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: Methyl Methacrylate Copolymer

End Uses: Electrical/Electronic Applications, Prototyping, 3D Printing Resins, Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic