Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Highlights

MINEX® ST functional fillers are produced from nepheline syenite; a naturally occurring, silica deficient, sodium- potassium alumina silicate. Automated scanning electron microscopy confirms they contain less than one-tenth of one percent crystalline silica. No free crystalline silica is detectable in the mineral complex. All MINEX® ST grades are processed

and sized with rigid adherence to Covia’s QIPSM quality assurance programs. Consistently uniform chemistries, size distributions, and top size controls ensure reliable performance.

Applications & Uses

- Product Applications

MINEX® ST grades are easily dispersed in a wide range of advanced resin systems from industrial primers and topcoats to aerospace, automotive, marine, plus the next generation paint/primer interior and exterior architectural systems for ultimate performance.

Properties

- Typical Properties

Value Units Test Method / Conditions Particle Size (Passing through 200 Mesh) 0.03 % - Particle Size (Passing through 325 Mesh) 0.08 % SediGraph Median Particle Size 8.6 μm SediGraph Hegman Value 4.8 NS - pH 10.3 - AFS 113-87-S Moisture Content 0.05 % ASTM C-566 Oil Absorption 22.4 ml ASTM D-281 Brightness 85.8 - TAPPI - Chemical Analysis

Value Units Test Method / Conditions Iron Oxide 0.091 % -

Technical Details & Test Data

- Test Data

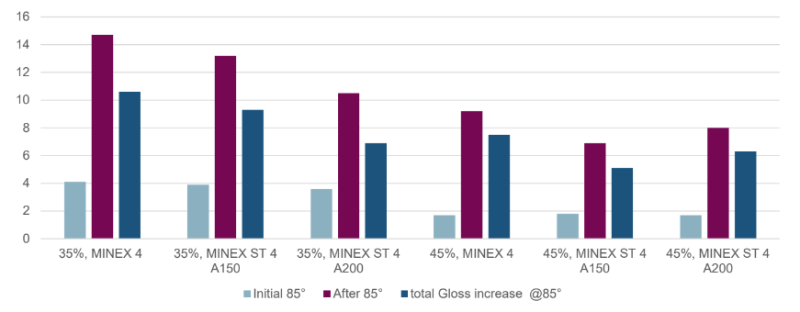

Gloss before and after 200 abrasive scrub cycles.

Burnish resistance improved for MINEX ST 4 at both 35 and 45% PVC.

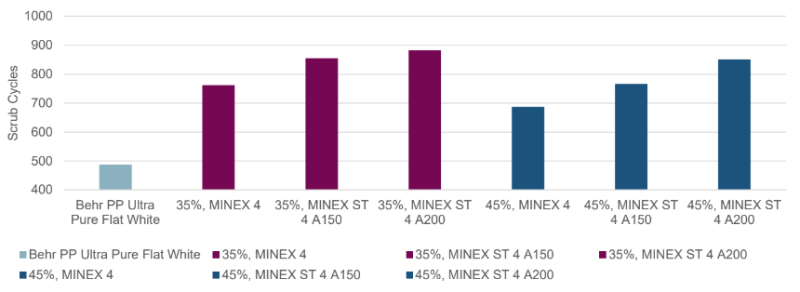

Scrub Resistance ASTM 2486

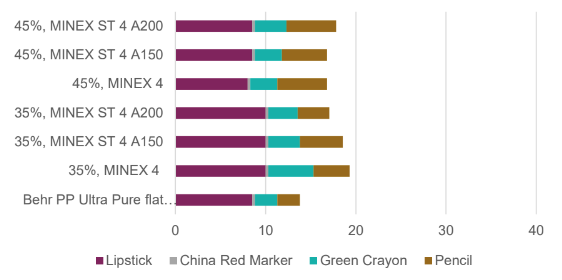

Hydrophilic stain resistance ASTM D8428-20

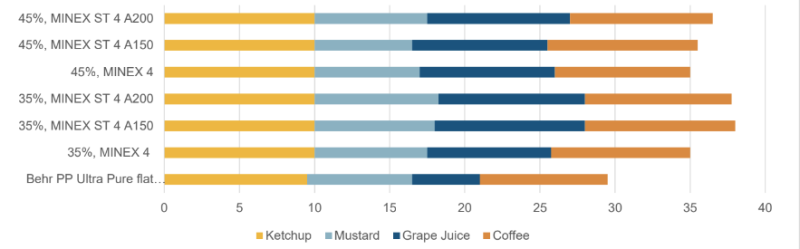

Hydrophobic stains ASTM D8428-20

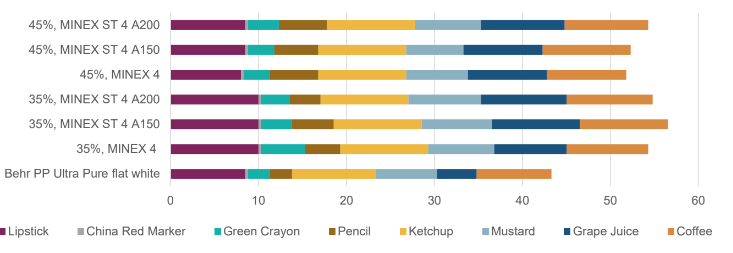

Overall: Combined stain resistance