Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Advantages

- Saves Money. Reduces the need for inventory of multiple products and, in many cases, disposal fees.

- Multi-Task Capability. TZ-PAINT PREPTM can be used in Virtually any cleaning application that requires the removal of oil or grease.

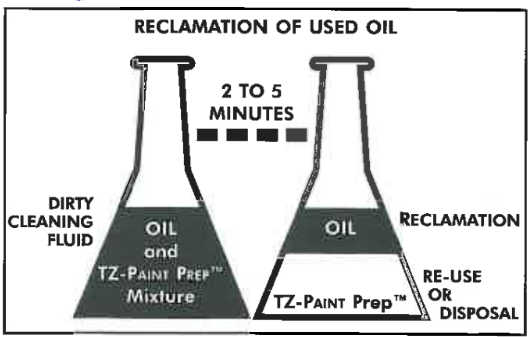

- Recyclable. Easily separates contaminants for reclamation, disposal or reuse of cleaner.

- High Dispersion Capability. Reduces usage.

- Ready-to-Use. No wastcd time on the job; eliminates mixing mistakes.

- Non-Abrasive. Will not scratch metal, plastic or painted surfaces.

- Reduces Causes of Major Workplace Problems. Helps eliminate accidents and conditions which frequently lead to Workers Compensation claims and employcc down- time, inhalation problems, eye damage and contact dermatitis/chemical burns.

- USDA Authorized. Tz-PAINT PRETM is acceptable as a general cleaning agent on walls, ccilings, structures and equipment, or for use with steam or mechanical cleaning devices in all departments of establishments operating under the Federal meat, poultry, shell egg grading, and e88 products inspection program

- Aqucous Based. In many cases, after P.O.T.W. testing, the used TZ-PAINT PRHPT is admissable into sewer treat- ment systecms for significant savings on disposal costs.

- Non-Toxic, Non-Flammable, Non-Hazardous. Safer for users, low-odor, no toxic fumes. Replaces flammable solvents and caustics, while improving the safcty of the work environment. Not considered or regulated as a hazardous material by either EPA or OSHA.

- Biodegradable. Safe for the environment.

- Benefits

- Cleans better than solvents

- Easy-to-use

- No-rinse capability

- Non-hazardous

- VOC compliant

- Product Highlights

The Safe, Environmentally Friendly Way to Prepare Metal, Plastic and Wood Surfaces for Coating Goating pontaneous Oil/Water Spliting Cleaner with High oil Dispersion Capability Water Based VOC Compliant NO CFC's USDA Authorized

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Applications

- TZ-Paint Prep has undergone years of field trials and testing to meet the stringent technical requirements of the paint and coatings industry for surface preparation.

- Coverage rates vary depending on usage rate, surface porosity and texture.

- Building Maintenance: Hotels, Schools, Offices

Transportation Industry

- Automobile Dealers

- Trucks, Busses

- Departments of Transportation

- Gas and Service Stations

Institutional Foods

- Restaurants

- Fast Food Chains

- Food Processing Plants

- Industrial

- Warehouses

Government

- Federal, State, City Maintenance

- Schools, Fire Departments

- Police Departments

- Aerospace

- Manufacturing

- Medical Institutions

TZ-Paint Prep™ the PREMIER Cleaning/Surface Preparation Product for Replacement for solvents and low State-of-the-Art Water ReducibleImproves adhesion and paint low

Acrylic, Epoxy, Urethane and Other Coatings- Superior eleaning ability

- Replacemeni for solvents and ow-

- Performance, high odor detergents

- Improves adhesion and paint flow

- Reduces delamination problens

- Encreases paint life

Properties

- Physical Form

- Appearance

- Amber

- Odor

- Very Low

- Soluble in

- Water

- Typical Properties

Value Units Test Method / Conditions pH 10.5 - - Weight 8.4 Ibs./gal. - Rinsability Excellent - - Fiash Point Non-Flammable - - Abrasives None - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Regulations

TZ-Paint Prep™ meets federal regulations for safe, non-toxic chemicals. TZ-Paint Prep is biodegradable, non-hazardous and VOC compliant.

Technical Details & Test Data

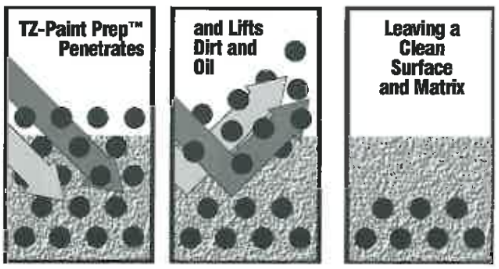

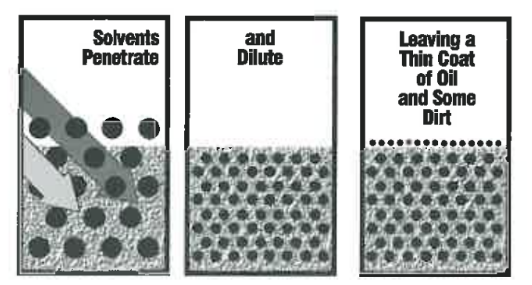

- Why TZ-PAINT PREP Cleans Better than Solvents

TZ-Paint Prep" penetrates porous substrates, loosens oil and other contaminants and lifts them up and out. On dense substrates such as metal, TZ-Paint Prep" lifts con- taminants up and off. Since TZ-Paint Prep" is aqueous, the surface can be rinsed, leaving a clean surface and matrix.

Solvents dilute and disperse oil and contaminants, driving them more deeply into the substrate, which allows them to gravitate to the surface later. The surface is left moderately ciean, but with a thin coating of oil which can adversely affect bonding.

- Directions

- Manually remove heavy contaminant and debris

- Apply TZ-PAINT PREPT sufficient to wet the surface, or soak

- Allow to set or soak for 5 - 15 minutes, keeping all surfaces wet

- Wipe, broom, power scrub, powerwash

- Rinse with water or diluted TZ-PAINT PREPTM

- Repeat where necessary

Apply 17-PAINT PREPT, with a spray, rag, broom or brush and allow to sit

for 15 minutes, Mask, special clothing and gogges sometimes needed

where appropriateTZ-PAINT PREPTM Can be used with equipment Such asS a power

washer, injected steam cleaner, rag, broom or brush. For best resulis, keep all surfaces wet with TZ-PAINT PREPTM during cleaningAfter cleaning, power rinse or hose, and allow surfaces to dry thoroughl: Squeegee

or vacuum up for disposal. Disposal is easy, because TZ-PAINT PREPTM is not a hazardous material.Allow to dry thoroughlb: The the final step is to apply the coating with a brush, roller, or spray: Thorough preparation withTZ-PAINT PREPTM enhances the bond between surface and coating, thus extending the life of the finish.