Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Product Highlights

- Summer version

- Excellent fiber wet-out

- Low styrene emission

- No sagging on vertical surfaces

- Good mechanical properties

- Optimum HDT

Applications & Uses

- Markets

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Primary Usages

AC units and system components, applications which require mechanical strength such as GRP parts for marine and automotive industry.

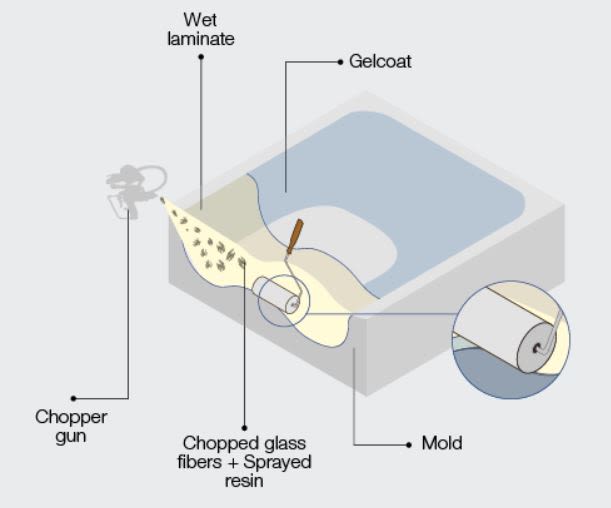

- Spray-up Application

Glass fiber roving and catalyzed resins are sprayed on mold surface with a chopper gun. Any air trapped after spraying is released with a roller.

Spray-up production steps:- Apply wax-based release agent on mold surface (ref. mold release waxes)

- Apply gelcoat film with 500-800 micron thickness

- Check chopper machine pressure and peroxide ratio

- Spray polyester resin and chopped fibers with spray gun

- Continue spray-up until obtaining desired thickness

- Release trapped air with roller

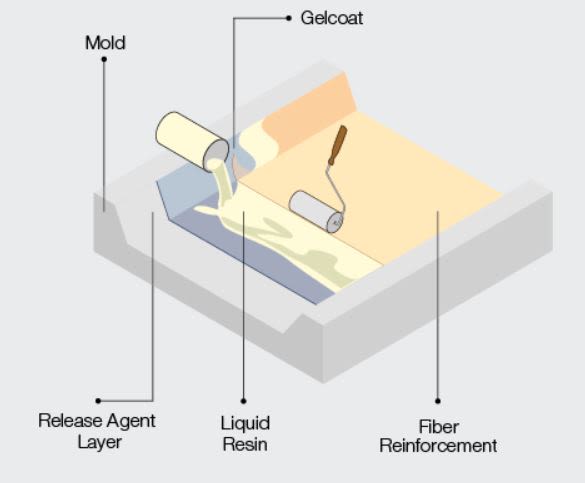

- Hand Lay-up Application

Hand lay-up production methods offer design flexibility, are low cost and a good choice for many producers. It is an ideal method for low quantity part manufacturing. Hand lay-up

production methods allow flexibility with part shapes and lamination design and have lower mold costs compared to other production techniques. Additionally, it is possible to obtain

desired mechanical properties with different fiber resin ratios.

Hand lay-up production steps:- Apply mold release agent on mold surface

- Apply 500-800 micron gelcoat film on mold surface

- After gelcoat has reached a certain cured state, lamination steps can begin

- Composite part should be trimmed after demolding

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity | 600-800 | cps | - |

| Monomer Content | 41 - 44 | % | - |

| Flexural Strength | 140 | MPa | - |

| Tmax | 180 | °C | - |

| Barcol Hardness, 934 | 48 | Barco | - |

| Volumetric Shrinkage | 8, 2 | % | - |

| Tensile Strength | 68 | MPa | - |

| Gel Time | 38 - 42 | min | - |

| Elongation at Break Tensile | 2, 2 | % | - |

| HDT (0,45 MPa] | 86 | °C | - |

| Remarks | OT1, OT4 | - | - |

Technical Details & Test Data

- Diagram

- Diagram

- Availability

Packaging & Availability

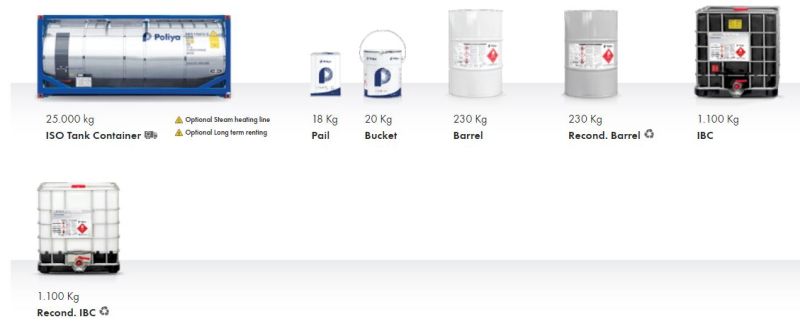

- Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.