Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

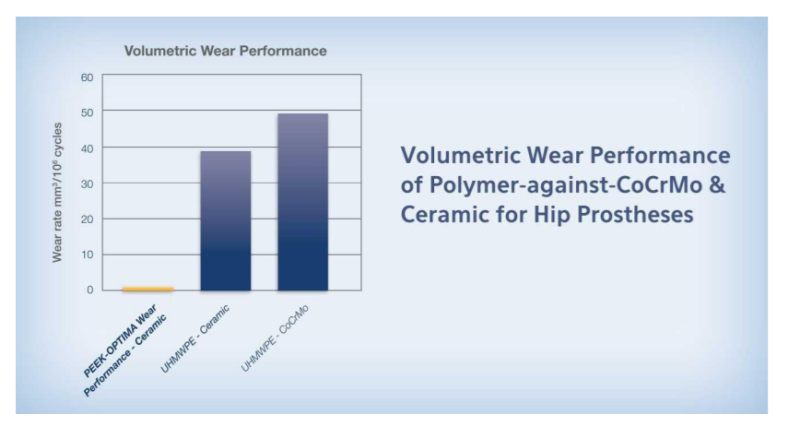

SUPERIOR WEAR RESISTANCE

Superior wear performance against hard counter faces, backed by accepted and validated wear-screening tests.

ELASTICITY SIMILAR TO BONE

With a bone-like modulus, PEEK-OPTIMA Wear Performance helps minimize stress shielding and stimulates bone healing.

STRONG AND DURABLE

The polymer is highly resistant to creep3 and fatigue and can be sterilized repeatedly without degradation.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Applications

Designed for bearing applications against hard counter faces, such as metal and ceramics, PEEK_x0002_OPTIMA Wear Performance* combines the material properties of PEEK-OPTIMA Natural with carbon fiber technology. In order to meet the critical demands of orthopedic joint arthroplasty, PEEK-OPTIMA Wear Performance offers:

- Superior wear performance against hard counter faces Backed by accepted and validated wear-screening tests

- Design and processing versatility ideal for new arthroplasty devices

- High resistance to creep and fatigue

- Modulus similar to bone for reduced stress shielding and to stimulate bone healing

- Sterilize repeatedly with no degradation using steam, ethylene oxide, gamma or Sterrad® plasma

- Compatible with x-ray, CT and MRI imaging techniques

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melt Viscosity | 0.71 | - | Capillary Rheometer |

| Density | 1.43 | g/cm³ | ISO 1183 |

| Tensile Strength (Yield) | 162 | MPa | ISO 527 |

| Tensile Elongation (Break) | 2.2 | MPa | ISO 527 |

| Flexural Modulus | 12 | % | ISO 178 |

| Flexural Strength | 246 | GPa | ISO 178 |

| Shear Strength | 95 | MPa | ASTM D732 |

| Shear Modulus | 2.2 | MPa | ISO 15310 |

| Compressive Strength | 200 | GPa | ISO 604 |

| Compressive modulus | 12 | MPa | ISO 604 |

| Poisson’s Ratio | 0.41 | GPa | ASTM D638 |

| Rockwell Hardness | 104 | N/A | ASTM D785 |

| Izod Impact (Unnotched) | 37 | M Scale | ISO 180 |

| Izod Impact (Notched) | 6.4 | kJm-2 | ISO 180 |

| Water Absorption (24 hours) | 0.5 | kJm-2 | ISO 62 |

| Melt Temperature | 340 (644) | Wt. % | DSC |

| Coefficient of Thermal Expansion Below Tg | 0.7 | °C (ºF) | ASTM D696 |

| Coefficient of Thermal Expansion Above Tg | 0.8 | 10-5°C-1 | ASTM D696 |

Technical Details & Test Data

- Volumertic Wear Performance