Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

- Product Families

- Ingredients

Buffer substances and complexing agents.

Features & Benefits

- Labeling Claims

- HII Features

- Properties

deconex ® CIP alu-pro points out the following special features:

- Liquid.

- pH-neutral.

- Rewindable.

- Manually and mechanically applicable.

- Foam-free in the spray cleaning procedure.

- Compatible with aluminum and anodised aluminum.

- Can be used without neutralization step.

- Silicate free.

- Surfactant free.

- Suitable for validated cleaning: fully documented according to cGMP; toxicological assessment reports are available.

Applications & Uses

- Markets

- I&I Cleaning Applications

- Applications

Dosage

The optimal dosage depends essentially on the stubbornness and amount of contamination, the cleaning equipment used and the cleaning process. The use of fully salted water improves the cleaning properties and reduces the need for cleaners. deconex® CIP alu-pro is most commonly used in a concentration of 5 - 20 L/L.

Usage

deconex® CIP alu-pro is used in:

- Chemical Industry

- Biotechnology

- Cosmetic industry

- Pharmaceutical Industry

- Instructions for Use

Due to the composition, deconex® CIP alu-pro for optimal cleaning results with sensitive materials. The special formulation prevents a corrosive attack on the treated surfaces and thereby prolongs the life of the cleaning good. Ideal for aluminum items and various aluminum alloys, as well as for demanding, anodized aluminum parts. In principle, all water-resistant types of oxidized aluminum with deconex® CIP alu-pro can be cleaned. In view of the variety and variety of types of anodised aluminum, we recommend, for safety reasons, the durability of anodised aluminum over deconex® CIP alu-proat use temperature to check. The addition of deconex is particularly suitable for removing stubborn residues.® CIP surf as an excellent additive. When using deconex® CIP alu-pro does not necessarily require a subsequent neutralization step. The neutralization z. B. with deconex® However, CIP fresh can significantly shorten the rinsing steps and rinsing times. If the cleaning is done in city water, the acidic rinsing removes possible residues of mineral and metallic ions. After cleaning, a sufficient rinse with fully salted or purified water should take place. The sufficient flushing ensures nonstick surfaces.

Properties

- Physical Form

- Appearance

- Clear, Colorless

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH value (1 g/100 g in RE water) | approx. 7 | - | - |

| Density (Concentrate) | 1.2 | g/mL | - |

Technical Details & Test Data

- Material Compatibility

Suitable for: Aluminum, under certain process parameters anodized aluminum such as ARC-20, GHA® , Hard Anodised / PTFE, HARTCOAT® -GLATT (25 µm), HART-COAT® (30 ,m, 50 µm), Trenn Coat ® 10 MD, MICRALOX® , Stainless steel, Borosilicate glass, Polyethylene (HDPE), Polypropylene (PP), Polyvinyl chloride (PVC), Polyamide (PA), Teflon® (PTFE), Plexiglas® (PMMA), Polycarbonate (PC).

deconex® CIP alu-pro is not suitable for anodized aluminum surfaces that are water resistant. For non-named materials, you can conduct your own compatibility studies or order from Borer Chemie AG.

- Tips For Cleaning Anodized Aluminum

Anodized Aluminum

Aluminum is chemically very reactive. A natural, thin oxide layer thereby forms a protective barrier on the metal surface and prevents corrosion. However, this native alumina layer is only a few nanometers. Aluminum parts and aluminum alloys are anodized to increase the oxide layer thickness and achieve better corrosion resistance. Aluminum is chemically very reactive. A natural, thin oxide layer thereby forms a protective barrier on the metal surface and prevents corrosion. However, this native alumina layer is only a few nanometers. Aluminum parts and aluminum alloys are anodized to increase the oxide layer thickness and achieve better corrosion resistance.

Quality aspects

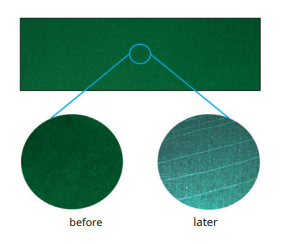

The physical properties of the oxide layer are influenced by its composition, thickness and fine structure. Many different aluminum alloys, a wide range of anodizing and sealing methods, the doping of the oxide layer with foreign substances and other surface treatments such as coloring or lubrication, the different coating thicknesses, the degree of crystallinity and the various factors. Behavior of the eloxal layer. before later. As a result, the durability of the oxide layer can be poorly predicted under various conditions.

Precautions when cleaning

Some precautions must be taken when cleaning anodized aluminum. The oxide layer is not only susceptible to strongly alkaline and acidic conditions, but also to other process parameters, such as the concentration of the cleaning agent, the cleaning time or the temperature. The same cleaning agent used at an elevated temperature, without sufficient rinsing after the cleaning step or over a long period of time, can allow the corrosive attack on the underlying aluminum. Possible causes are the removal of sealants and / or dyes, the thermal micro-crack formation and an opening of the ion exchange path, etc. In the case of certain oxide layers, cracks are even formed only by the heat load, for example when using pure water at temperatures above 70°C - 80°C. Freshly anodized layers can also cause problems, although an aging process of the oxide layer can sometimes improve their resistance. Taking all these aspects into account, it is not possible for us to recommend a universal cleaning process for anodised aluminum. For the appropriate cleaning process, you can carry out your own compatibility studies or commission the development of suitable processes from Borer Chemie AG. We are always available for your inquiries on these topics, in order to achieve optimal results together. Please contact us regarding the specialized cleaning of your anodized aluminum parts.

- Cleaning Anodized Aluminum

An anodized aluminum surface before treatment and after 5 minutes in clean water of 70°C

Packaging & Availability

- Packaging

The bindings, closures and labels are made of recyclable polyethylene.