Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- Advanced Oil and Water Emulsion Formula. • Self-leveling formula, with superior flow and defoaming properties.

- All the design advantages of an oil (OMU) – ambering tones.

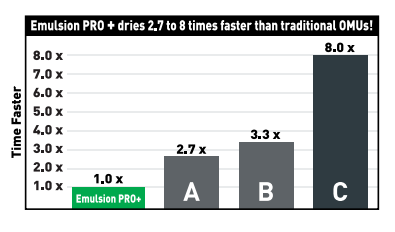

- All the advantages of a waterbased formula including speed of application and improved dry times - which allows for more projects throughout the year.

- All the advantages of a waterbased formula including low odor, and non-flammability (compared to a traditional oil/OMU) – which allows for less potential jobsite issues.

- Available in Commercial Gloss, Commercial Semi-Gloss, Commercial Satin and Commercial Super Matte.

- Product Highlights

Emulsion® PRO+ is a one-component, ambering, commercial grade, self-leveling sealer & finish. This product is an excellent choice for professionals that are looking to make the transition from OMUs (oil-modified urethanes) to waterbased finishes, or for professionals wanting an ambering finish that delivers a rich look of traditional oil but with all the advantages of a commercial waterbased finish. It is designed to apply, defoam, and self-level faster than any other oil & water sealer/finish on the market. It is is an excellent choice for professionals that are looking to make the transition from OMUs (oil-modified urethanes) to waterbased finishes.

Professional Innovation

Emulsion® PRO+ is a one-component, ambering, commercial grade, self-leveling sealer & finish. This product contains an oxidative crosslinking polyurethane (OCP), and is ideal for use in Residential, Commercial, or Sport Wood Flooring applications. Emulsion PRO+ has many attributes of a traditional OMU - ambering, rich tones, ease-of-application, PLUS it has all the advantages of a waterbased sealer/finish – speed of application, fast dry times, low-odor, non-flammable, water cleanup, and multiple coats can be applied in one day.

- Emulsion PRO+ Advantages

- One-Component, Extended Pot Life

- Ambering, Enhancebeauty of wood

- Low VOC, Low Odor

- Is not OMU | Non-Flammable

- VOC Compliant, Compliant in U& Canada

- Available in 4 sheens: Commercial Glos(>85), Commercial Semi-Glos(45-60), Commercial Satin (25-30), Commercial Super Matte (5-15) 60° on wood.

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Recommended Uses

- An excellent choice for professionals transitioning from traditional oil (OMU) to waterbased sealers/finishes.

- Ideal for enhancing the natural beauty and characteristics of wood flooring.

- Ideal for use in Residential, Commercial, or Sport Wood Flooring applications.

- Application

Read and understand technical data sheet and associated safety data sheet completely before beginning installations. Always use appropriate personal protective equipment. Prior to beginning a project, apply in an inconspicuous area to test and become familiar with your complete application method and to ensure product satisfaction. Follow industry standards and flooring manufacturer’s recommendation for acclimation, design, layout, and application of wood flooring materials.

Recommended Applicators

Professional T-Bar/Pad, Roller, Paint Pad, or Brush can be used.

Mixing

Use a stir stick, or rock container several times, to thoroughly mix and re-disperse any settlement. Alternatively, shake well before using – then set aside for at least 20 - 30 minutes prior to use. It is important to stir (not shake) from time to time to prevent settling.

Adding Water

Up to 12 ounces of water can be added per gallon of finish. Adding water will increase the flow and level time during situations of high temperature and low humidity.

Surface Preparation

Sand floors using accepted NWFA/MFMA procedures. PLEASE NOTE: After final sanding, be sure to record moisture readings throughout installation. Moisture readings during installation provide a baseline/benchmark for when to begin next application steps. Always make sure moisture is within acceptable levels for region of the project. Thoroughly vacuum floor prior to application. Tack with clean dry towels until all dust has been removed.

Finish Application (Pre Application)

Always maintain adequate temperature/ventilation during all phases of the coating and drying process.

- Restrict air flow during application to help prevent premature drying.

- Measure and record moisture content of floor in several areas.

- Rinse applicator and remove all excess water. This also helps to remove loose fibers.

For New Installations / Newly Sanded Floors

Apply compatible stain, sealer, and/or paint as designed; allow to dry per directions, or longer depending on jobsite conditions. Followed by 2 coats of Emulsion® Pro+.

- T-bar Application: Pour a 4” wide line of finish along the starting wall. Using a clean, pre-dampened T-Bar applicator, draw the applicator in the direction of the grain of wood at a slight angle. While keeping the wet edge in the middle of the T-Bar, move the finish puddle with the grain of wood, wall to wall. At the end of each run, turn the applicator towards you and pad out the applicator parallel to the wet edge. Feather out all turns and touch up any missed areas if seen right away.

- Roller Application: Using a clean, pre-dampened microfiber roller, apply finish in the direction of the grain of wood. Apply evenly at the recommended coverage rate. Feather out during application to avoid streaks, puddles, lap and turn marks.

For Recoating Floors

Dust-free Process: Please refer to Basic Coatings TyKote® Dust-Free Refinishing System Instructions.(System includes IFT™, Squeaky® cleaner, and TyKote® .) Screen And Recoat Process: Properly clean, lightly abrade with 180 grit screen or equivalent, vacuum, and tack floor to achieve surface that finish can properly adhere to. Always do adhesion test in inconspicuous area prior to starting project.

- Allow a minimum of 30 - 45 minutes to level.

- After finish levels, allow increased and balanced air movement and fresh air exchange. Proper air movement will help dry the finish.

- After a minimum 2 - 3 hours (under good conditions), re-measure moisture content. If moisture content is not equal to the first reading, allow more dry time.

- When proper moisture content is achieved, apply another coat of finish following same application procedures described above.

- If necessary, abrade between coats to remove debris, hair, drips, etc. or if the 24-hour window between coats has elapsed. Abrade with the pad-and-strip system using 180 - 240 grit sanding strips.

- Between coats, vacuum and tack with a Basic Coatings Microfiber Mop dampened with Squeaky®.

- If the 24-hour window has elapsed, the TyKote® Dust-Free Refinishing System is an alternative to screening the floor. Refer to TyKote application procedures for details.

- Additional coats can be applied for increased protection, especially in heavy-traffic or pet areas.

Basic Coatings recommends using a NWFA/MFMA/Industry Certified Professional.

Clean-up

Application tools should be thoroughly cleaned with water immediately after use.

Dry/Cure Time

Allow at least 2 - 3 hours between coats. Once you increase air flow, keep air movement for several hours to ensure proper curing. Please refer to specific product technical data sheet for specific product information. In general, light foot traffic after 24 hours is acceptable. Furniture can be carefully replaced, however finish is susceptible to marring and scratching until the finish is fully cured – approximately 7 days. Do NOT place carpet, rugs, or cover the finish for at least two weeks after the finish has dried.

Coverage

Average of 450 – 550 sq ft/gal (11 – 13 sq m/l), depending on wood flooring species, porosity, and other jobsite conditions.

Limitations

Do not apply over acrylic or waxed surfaces.

Floor Care

Use only Basic Coatings microfiber mop for first 7 days; no cleaners. Per industry recommendations, use walk-off mats at all entrance doorways to help keep out dirt and grit; sweep and vacuum daily; and use felt pads under furniture legs and appliances. Once fully cured, use only Basic Coatings Squeaky® Hardwood Floor Cleaner with microfiber mop for for routine maintenance.

Properties

- Odor

- Mild

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Solids Content | 24 - 28 | % | - |

| Chemical Resistance | Excellent | - | - |

| Defoaming | Excellent | - | - |

| Leveling | Excellent | - | - |

| VOC | max. 275 | grams/liter | - |

| Commercial Gloss (60° on wood) | min. 80 | % | - |

| Commercial Semi-Gloss | 45 - 50 | % | - |

| Commercial Satin (60° on wood) | 25 - 30 | % | - |

| Commercial Super Matte (60° on wood) | 5 - 15 | % | - |

| Dry Time | 2 - 3 | hours | - |

| Clean Up | Water | - | - |

| Coverage | 450 - 550 | sq. ft./Gallon | - |

| Flash Point | min. 200 | ºF | - |

Technical Details & Test Data

- 9

Safety & Health

- Precaution

Keep out of reach of children. For industry use.

Warning - Causes serious eye irritation. Wear eye or face protection: Recommended: safety glasses. Wash hands thoroughly after handling. Keep closures tight and upright to prevent leakage. Keep container closed. In case of spillage, absorb and dispose of in accordance with local applicable regulations.

First Aid: If In Eyes: Rinse with gentle stream of water. Call a physician if irritation persists. If Swallowed: Do NOT induce vomiting. Rinse out mouth with water. Call a physician.

Packaging & Availability

- Packaging

- 1 U.S. (3.7 L) gallon container (4/case)

- 5 U.S. (18.9 L) gallon pail

- Availability

Waterbased Finish Sheen 1 Gallon 5 Gallon VOC Emulsion PRO™

Gloss B0675-4312 B0675-0512 max. 275

Semi-Gloss B1620-4312 B1620-0512 Satin B1619-4312 B1619-0512 Super Matte B1623-4312 -

Storage & Handling

- Storage

- Bring to room temperature and mix thoroughly before using.

- Do not store above 120°F (49°C). KEEP FROM FREEZING

- Shelf Life - 1 year shelf life under proper storage conditions.