- Polymer Name:Polyetheretherketone (PEEK)

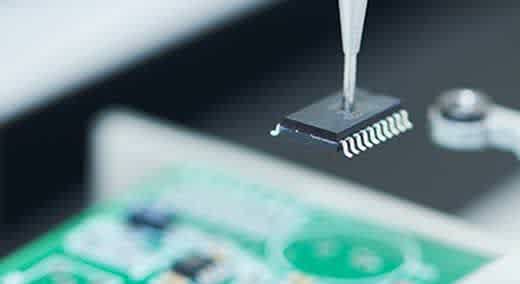

- Processing Methods:Extrusion, Injection Molding, Isostatic Molding

- Fillers Included:Glass Fiber

- Materials Features:High Strength, Oil Resistant, High Viscosity, Good Compressive Strength, Low Shrinkage, Wear Resistant, Solvent Resistant, Low Warpage, Creep Resistant, High Stiffness, Low Flammability, Good Thermal Stability, Acid Resistant, Alkali Resistant, High Temperature Application, High Pressure Applications, Chemical Resistant, Hydrocarbon Resistant, Gasoline Resistant, Dimensional Stability, Semi Crystalline, Salt Water/Spray Resistant, Crack Resistant, Good Mechanical Properties, Good Rigidity, Water Resistant, Flame Resistant, Abrasion Resistant

- Color:Natural

VESTAKEEP® 4000 GF30 is a glass fiber-reinforced (30%) polyether ether ketone specifically designed for injection molding applications. This semi-crystalline polymer offers superior mechanical, thermal, and chemical resistance, ensuring exceptional performance. Parts manufactured from VESTAKEEP® 4000 GF30 exhibit low flammability, enhancing safety. Compatible with common injection molding machines for thermoplastics, this material simplifies the manufacturing process. Experience the reliability and versatility of VESTAKEEP® 4000 GF30 in your injection molding applications. With its glass fiber reinforcement, it provides enhanced strength and rigidity, while maintaining excellent properties in challenging environments. Choose VESTAKEEP® 4000 GF30 for its superior mechanical performance, thermal stability, chemical resistance, and ease of processing, enabling the production of high-quality injection molded parts.