Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Highlights

- Enhances Flexibility

- Abrasion Resistance

- Exhibits Hydrolytic Stability

- Provides Oil & Chemical Resistance

- High Clarity

- High Tensile Strength

- Provides Excellent Weatherability

Applications & Uses

- Markets

- Applications

- Recommended Application

- Foil Coatings

- Optical Coatings on Polycarbonate

- Weather-Resistant Coatings

Properties

- Uncured Properties

Value Units Test Method / Conditions Pt-Co Color 25 APHA - Viscosity (50 °C) 30000 cP - Pt-Co Color (APHA) 25 - - Refractive Index (25°C) 1.475 - - Density (25°C) 1.17 g/cm3 -

Technical Details & Test Data

- Typical Formulations

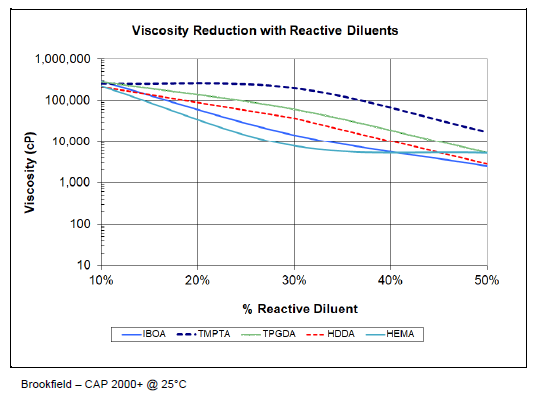

Test Formulation Name I30 I50 TM50 TP50 H50 HE30 BR-543

70 50 50 50 50 70 IBOA 30 50 TMPA 50 TPGDA 50 HDDA 50 HEMA 30 Omnirad® 481

2 2 2 2 2 2 Viscosity, 25°C (CAP2000+) 14.000

2,500 17,000 5,300 2,800 7,900 Cured Mechanical Properties

Property I30 I50 TM50 TP50 H50 HE30 Tensile Strength, (psi, ASTM D882) 480 1,300 2,900 1,600 2,400 450 Elongation (%, ASTM D882) 85 130 4.1 10.9 10.8 95 Elastic Modulus (ksi, ASTM D882) 1.2 9.7 100 35 50 1.8 Durometer Hardness 56A 74A 63D 43D 54D 42A Pencil Hardnes (ASTM D3363) 0.86 0.55 1.31 1.23 1.00 4.68 MEK Double Rubs (#) 6 3 46 16 15 10 Tg(DMA)=-47°C; Peak tan delta; cured with 2 phr of Omnirad® 184 Adhesion Properties

Substrate I30 I50 TM50 TP50 H50 HE30 Aluminum XX XXX X Cold Rolled Steel XX PET XX XXX XX XXX PMMA X XXX XXX Polycarbonate X XXX XXX XX XXX Stainless Steel XX X X - Recommended, XX - Highly Recommended, XXX - Strongly Recommended

- Viscosity Reduction with Reactive Diluents