Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Base Oil Type

- Chemical Family

- Chemical Name

- Product Type

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Plastics & Elastomers Functions

- CAS No.

- 9006-65-9

- EC No.

- 618-433-4

- Technologies

- Product Families

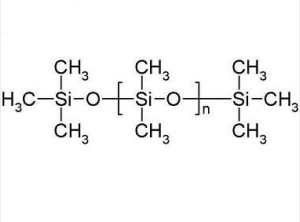

- Chemical Structure

Features & Benefits

- Labeling Claims

- HII Features

- Industrial Additives Features

- Materials Features

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Home Care Applications

- Application Details

- Release agent

- Lubricant

- Hydraulic fluid

- Anti-foam agent

- Water-repellent agent

- Liquid dielectric for electrical and electronic equipment

- Heat-transfer oil

- Polish additive

- Plastics additive

- Additive for textile and fiber auxiliaries

Due to WACKER® AK 2000 many diverse applications, no general processing information can be provided.

- Parameters will vary from application to application.

- Available in a range of viscosities, WACKER® SILICONE FLUIDS AK are miscible with each other in any ratio. The standard product's viscosity can thus be altered to suit your individual needs.

- WACKER® AK 2000 is a non-polar liquid and is immiscible with polar solvents such as water or short-chain alcohols. In aliphatic and aromatic hydrocarbons, chloro hydrocarbons, ethers, esters, ketones and higher alcohols, WACKER® AK 2000 is soluble in any proportion.

- Before the product is used with solvents for the first time, it is advisable to perform a lab-scale test. When solvents are used, please remember to read the appropriate hazard information.

- For pharmaceutical applications, we recommend specialty silicone fluids from our SILFAR® line.

- Silicone fluids from our BELSIL® line are available for the cosmetic sector.

- Whenever particularly high heat and shear resistance is required, we recommend silicone fluids from our AK stab, AK visc and AKC product lines. Specialty grades of the product (available as WACKER® PLASTICIZER) will be needed for use as a silicone plasticizer in RTV-1 sealants.

Properties

- Color

- Physical Form

- Odor

- Odorless

- Soluble in

- Esters, Ketones, Ethers, Higher alcohols, Aliphatic and aromatic hydrocarbons, Chloro-hydrocarbons

- Typical Properties

Value Units Test Method / Conditions Density approx. 0.97 g/cm³ - Flash Point approx. 263 °C ISO 2719 Ignition Temperature 450 °C DIN 51794 Kinematic Viscosity (at 25°C) approx. 2000 mm²/s DIN 53019 Refractive Index (at 25°C) approx. 1.404 - DIN 51423 - Properties

- Minimal change in physical properties over a broad temperature range

- Excellent water-repellent properties

- Good dielectric properties

- Low surface tension and thus high surface activity

- Chemically highly unreactive

- Low solidifying point

- High flash point

- High heat resistance

- Good solubility in a wide range of solvents

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Quality Standards

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage Information

Maximum temperature allowed during storage and transportation: 50 °C.