Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Electromagnetic effects (EME)

- Lightning strike protection

- EMI shielding

- Repairing

- Electrical networks on composite skins

- Ground plane

- Benefits

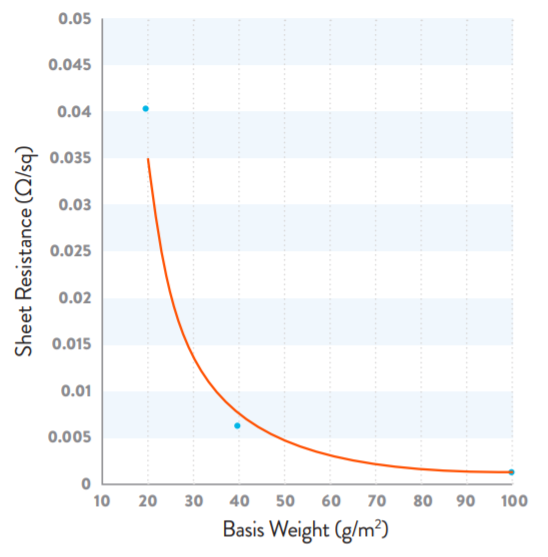

- 3–100x lower sheet resistance than metallized nonwoven competitors at similar areal weights

- 50%–75%+ lighter than expanded copper foil (ECF)

- Vastly superior shielding performance (>100 MHz) compared to ECF

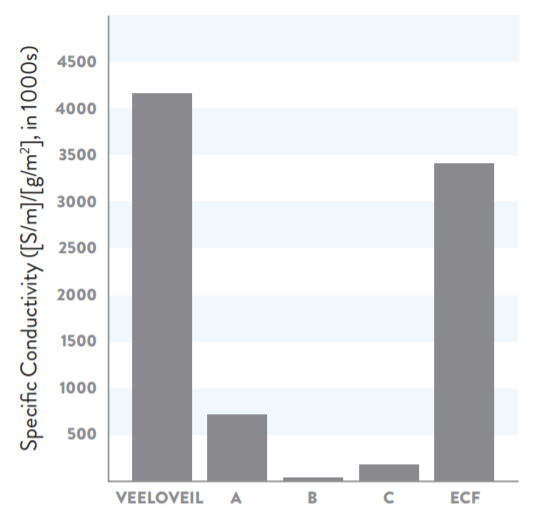

- 4.5–300x higher specific conductivity than other metallized nonwovens

- Available in commercially integrated product forms (pre-preg, film adhesive, surfacing film)

- Samples available for characterization, hand lay-ups, and testing

- 12" or 36"-wide rollstock (dry)

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

- Applications

- Delivering differentiated material solutions

- Multiple EME applications and systems

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Basis Weight (Dry) 20 - 80 g/m2 - Thickness 5.0 μm - Sheet Resistance 0.002 - 0.040 Ω/sq - Edge-To-Edge Electrical Uniformity (COV) max. 5 % - Electrical Anisotropy (MD/CD) max. 2:1 - - Shielding Effectiveness (30–100 MHZ ) 75 - 80 dB - Shielding Effectiveness (100 Mhz–1 GHZ ) 80 - 75 dB - Shielding Effectiveness (1–10 GHZ ) 75 - 55 dB -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Veeloveil Vs Metalized Nonwovens A,B,C And Expanded Copper Foil

- Sheet Resistance Vs Basis Weight

Packaging & Availability

- Veeloveil Outperforms Other Commercially Available Metallized Veils

- 3x less resistive and 36% lighter than the least resistive commercially available metallized nonwoven

- 4.5–300x better specific conductivity than COTS metallized nonwovens