Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Technologies

- Product Families

- Chemical Composition

Depending on the use conditions, stricter analysis limits apply to certain alloy elements.

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- Features

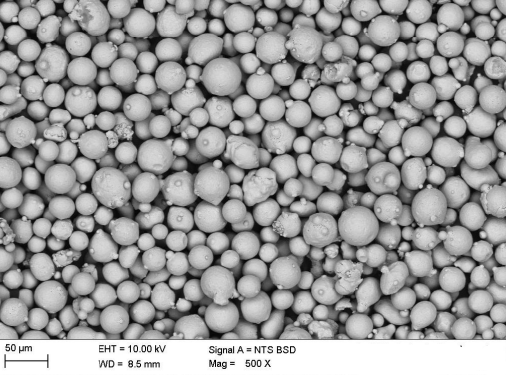

VDM® Powder 738LC is characterized by:

- spherical particles with low level of satellites

- high purity and reproducibility level

- low oxygen content

- small amount of porosity

- good flowability

- high apparent and tap density

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Applications

VDM® Powder 738LC can be used for a wide range of processes:

- Laser based additive manufacturing

- Electron beam based additive manufacturing

- Coatings

- Direct energy deposition

- Overlay welding

- Cold and hot isostatic pressing (CIP / HIP)

VDM® Powder 738LC can be used for many demanding applications. Originally, it was developed and used for static and rotating components in aircraft turbines such as housings, mounting elements and turbine blades and vanes because of the excellent oxidation resistance.

Properties

- Physical Form

- Chemical Properties

Value Units Test Method / Conditions Aluminum Content 3.20 - 3.70 wt. % - Boron Content 0.007 - 0.012 wt. % - Carbon Content 0.09 - 0.13 wt. % - Cobalt Content 3.00 - 9.00 wt. % - Chromium Content 15.70 - 16.30 wt. % - Iron Content max. 0.10 wt. % - Manganese Content max. 0.02 wt. % - Molybdenum Content 1.50 - 2.00 wt. % - Nitrogen Content max. 0.02 wt. % - Niobium Content 0.60 - 1.10 wt. % - Oxygen Content max. 0.03 wt. % - Sulfur Content max. 0.015 wt. % - Silicon Content max. 0.30 wt. % - Tantalum Content 1.50 - 2.00 wt. % - Titanium Content 3.20 - 3.70 wt. % - Tungsten Content 2.40 - 2.80 wt. % - Zirconium Content 0.01 - 0.08 wt. % - - Physical Properties

Value Units Test Method / Conditions Density (20°C) max. 8.11 g/cm³ - Melting Range 1230 - 1315 °C - - Physical Properties

Particle size distribution

μmFlowability Apparent density Tap density ASTM B213 ASTM B964 ASTM B212 ASTM B417 ASTM B527 15-53 Y Y Y Y Y Y - The test can be performed

Standard inspection certificate contains particle size distribution and chemical analysis.

- Microstructural Properties

VDM® Powder 738LC microstructure consists primarily out of a γ-phase matrix and the γ′ intermetallic phase of the form Ni3Al. The solid solution elements present are chromium, cobalt, tungsten and tantalum; these equally contribute to the structural stability of the alloy. Carbides and borides form the main grain boundary strengtheners.

Regulatory & Compliance

- Designations and Standards

Standard Material designation

SAE AMS 5410 C* *only chemical analysis except Zr.

Packaging & Availability

- Availability

According to the requirements of the powder based processes, VDM® Powder 738LC is available in a wide range of particle fractions from 15 to 250 μm. The typical powder atomization yield ranges from 0.1 to 300 μm. After atomization, the powder is sieved and air classified according to customers specifications. All production and handling operations are carried out under protective atmosphere (argon).

Standard particle fractions

Particle size distribution

[μm]Fine particle D10

[μm]

(tolerance +/-5 μm)D50

[μm]

(tolerance +/-5 μm)15-53 <15 μm max. 3% 22 35 The determination of the PSD is done by laser diffraction according to ASTM B822.

- Packaging

The whole production and packaging process at VDM Metals is under argon and the powder has no contact to atmos-phere. The standard powder is packed in plastic bags (5 kg/10 kg/20 kg) under argon inside of sealed plastic drums (6l).

Storage & Handling

- Handling

- Please note that powder transportation may result in segregation of particle sizes.

- Do not open the container in humid environment.

- After contact with air the powder has limited storability.

- Humidity can influence the powder properties.