Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 26471-62-5

- EC No.

- 247-722-4

- Technologies

- Product Families

- Functionality

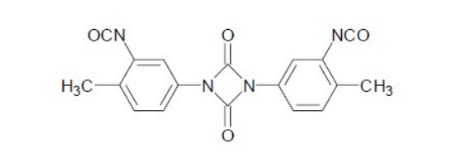

- Under mild reaction conditions, i.e. at up to approx 130°C in the absence of basic catalysts, it is primarily bifunctional, with a molecular weight of 348.

- Under more severe conditions (either at temperatures above 140/150°C or with the aid of highly basic catalysts at temperatures above 90°C) it remains primarily

bifunctional but with a molecular weight of 174, as the central uretdione group splits to form monomeric TDI.

- Chemical Structure

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

- Adhesion promoter for rubber-to-fabric bonding (polyester, aramid, polyamide). Applications include tire cord, conveyor belts, drive belts, hose, coated fabrics.

- Adhesion promoter for PVC-to-fabric bonding (polyester, aramid, polyamide). Applications include coated fabrics, conveyor belts.

- Vulcanizing agent for polyurethane rubbers like Millathane® 26, particularly when a high hardness is desired. Applications include industrial molded parts, rollers, ceramic tile molds.

- Crosslinker for heat-activated adhesion, coating or elastomer systems.

Properties

- Appearance

- Fine, white powder

- Typical Properties

Value Units Test Method / Conditions Molecular weight 348 - - Density approx. 1.48 g/cc - Melting Point min. 145 °C - Monomer Content min. 0.1 % - Screens (through 325 mesh) min. 99% % - Particle Size (less than 10 microns) min. 75% % Malvern

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Solubility

Grams of Thanecure® T9 Superfine per 100 cc of solvent 23° C 50°C 100°C Water - - - Toluene 0.1 2.0 18 Chlorobenzene 0.3 3.0 36 o-Dichlorobenzene 0.1 2.0 7 - Abrasion Resistance

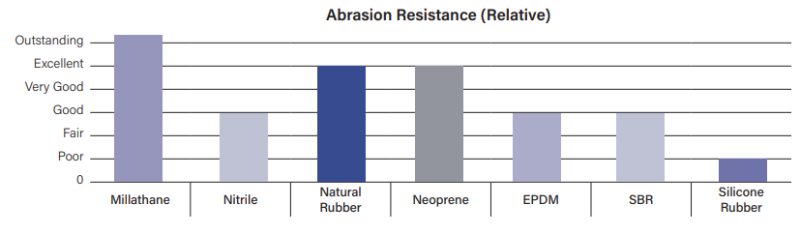

- Abrasion resistance is the ability of a surface to resist wearing due to contact with another surface moving with respect to it.

- High resistance to abrasion is important in applications like rollers, belting, and helicopter dust covers.

- The DIN Abrasion Test (ASTM D5963) is one of the most common tests for measuring abrasion resistance.

- It's where a rotating cylindrical sample is passed across a rotating drum of abrasive and the amount of sample volume lost is measured.

- Typical abrasion resistance values for Millathane millable urethane compounds is 50-80 mm³.

- Some compounds can have abrasion resistance values as low as 25 mm³, depending on the polymer, cure system, and formulation.

- Polyurethane rubber provides the highest abrasion resistance of any rubber, synthetic or natural.

- Laboratory tests do not always predict the advantage of Millathane compounds over other rubbers, but field experience often shows a tremendous improvement in product lifetime when millable urethane replaces conventional rubber.

Packaging & Availability

- Packaging Information

Package size/carton: 50 lb (22.7 kg) box.

Storage & Handling

- Storage Information

Stored under dry and cool conditions.