Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

PUSHING THE LIMITS OF THERMOPLASTICS WITH TECHNYL®

Now omnipresent in consumer goods and industrial products of all kinds, engineering plastics have long-proven their value in terms of technical performance and esthetics.

Their physical strength also makes them ideal as a lightweight replacement for metal in many cases.

Technyl® Star is a high-fluidity range that combines outstanding mechanical performance and incomparable processability, giving manufacturers the ability to push their own product innovations into new areas. With Technyl® Star, switching from steel and other metals to plastic is not only a valid technical option, but a quality choice that makes good business sense.

THE DESIGN FREEDOM AND ROBUSTNESS YOU’VE BEEN LOOKING FOR

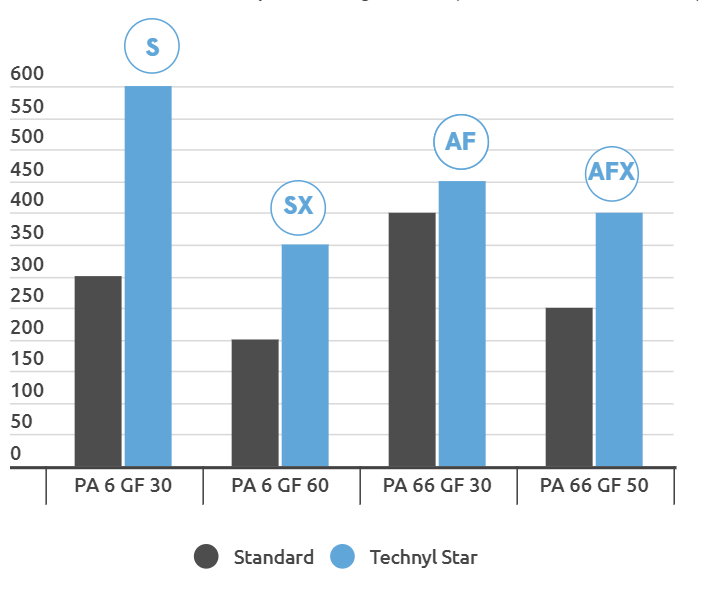

It’s time to unleash your product design potential. Technyl® Star offers a complete range of metal replacement solutions, from the medium-reinforced Technyl® Star S and AF for the ultimate in processing and molding efficiency, to highly-reinforced Technyl® Star SX and AFX for unprecedented weight reduction and rigidity.

- Main Benefits

- High strength polyamide material as a replacement for metal

- Efficient injection process saves cost, time, and energy in manufacturing

- End-of-life product recyclability

- Key Features

- Medium- to highly-reinforced grades

- Unique mechanical performance, rigidity, and resistance

- Flame retardant grades (with numerous color options)

- Excellent surface aspect

- Easy processing

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Technical Details & Test Data

- High Fluidity Technology

The Spiral Length Test (Rhodia method, mm)