Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Visual Appearance

This product is a white in color, highly consistent continuous filament glass fiber mat, supplied in rolls with trimmed edges. Each roll is significantly free of tears, holes, dirt, grease, foreign materials and non-uniform glass clumps or strands

- Visual Appearance

EXTRA SURFACE OPTION: Conformat N751 may be produced with an additional Surmat type veil on one or both surfaces enhancing the surface quality of the material. It has the additional advantage of lowering process costs by reducing the layers of mat material handled during pattern cutting or loading of molds by giving you two products in one. An additional price will apply. The Extra Surface is included in the weight per square foot.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Composites Processing Methods

- Binder System

Can be produced with any of Superior’s binder systems.

Properties

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

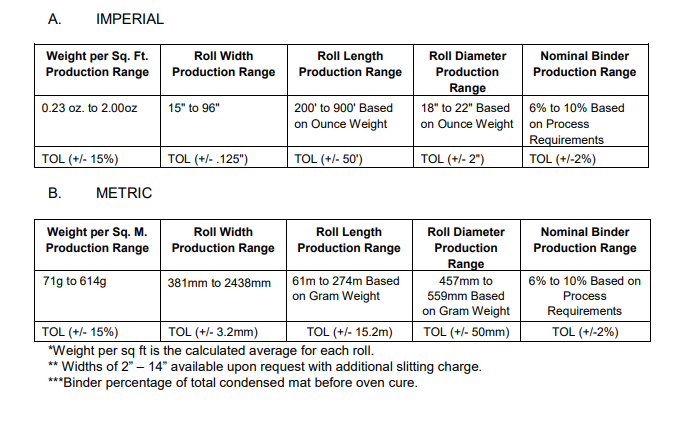

- Specifications

Packaging & Availability

- Packaging Type

- Packaging

All mats are wound onto (4”) I.D. (10.2cm) heavy duty cardboard cores. Each roll is individually contained within a polyethylene sleeve, placed on a 44" x 45” x 3.5” (11.00cm x 11.25cm x 8.89cm) wooden pallet and stretch wrapped for protection during shipment. Typically there are four to six (4-6) rolls per skid. Material 36-inch (91.4cm) wide or less may be double stacked on a skid.

Optional packaging methods are available. Additional charges may apply.

A. Three (3) inch I.D. (7.62cm) heavy duty cardboard core.

B. Cardboard box and skid.

C. Vacuum packaging for 10% space reduction.

D. Cardboard box, vinyl band with stretch wrap on skid.

E. Other methods available upon request.

Each roll is individually marked with product designation, roll number, roll width, roll length and roll weight.

Storage & Handling

- Storage

For best performance results, it is recommended that SHC products are stored at temperatures between 10º C and 35º C at relative humidity below 85%.

SHC Products should remain in the original packaging materials until just prior to use.