Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Keynotes

- Industrial-strength surface protection from humidity, moisture, tropical weather, direct spills

- Truly nano, invisible & non-conductive suitable for any electronics assembly, traceable or untraceable

- Strong adhesion to flexible circuits and PCBA components without affecting flexibility

- Universally adheres to virtually any plastic, glass, metal, ceramic surfaces and dries in seconds

- Non-Flammable - low transportation and maintenance costs, high ROI.

- Traceable / Untraceable in UV, supplied in various concentrations, viscosity, thickness and packaging, easy-to-apply by dipping, brushing, dripping, squirting or spraying

- Wide application in automotive, avionics, boating, consumer electronics, defense, LED, street lighting, medical, naval, PCB, solar, SMT, OEM manufacturing

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- 5-Step Self-curing Workflow

Step 1 - Sweep (Optional)

Establish clean surface area for protection - blow out dust, de-grease using STIRRI-SWEEPTM or an IPA cleaning solution. Cleaning the surface also helps to avoid bubbles.

Step 2 - Screen (Optional)

Tape/mask sensors, lenses, microphones, cavities, jacks and parts that would rather not be coated - not required if connectors can pierce through the coating to establish the link.

Step 3 - Sink/Spray/Spread/Spin

Dip into a bath preventing excessive evaporation, rotate manually or using an automated system. Adjust speed as necessary for cosmetic preference - higher speeds may lead to bubbling. Use QC-AidTM traceable coating to detect voided areas. Spray or brush onto surface or use drip and spin method to distribute the evenly the coating.

Step 4 - Dry(Optional)

HYDRACOAT dries in less than a minute and is safe to touch in only about 8 seconds. Fast-track curing in 60oC chamber for 10 minutes. Auto-cures at room temperature in 24h - no heating required.

Step 5 - Unscreen (Optional)

Remove tape and masks for a final look.

Properties

- Typical Properties

Value Units Test Method / Conditions Concentration (in fluoro-solvent) 0.2- 10 % - Film Thickness 0.1 - 0.6 μm - Boiling Point 80.0 °C - Viscosity (2% Polymer) approx. 0.82 cP - Viscosity (4% Polymer) approx. 1.85 cP - - Film Properties

Value Units Test Method / Conditions Contact Angle to Water approx. 115 Degree - Contact Angle in Oil min. 55 Degree - Surface Tension 8 - 12 dynes/cm Flammability No - - Full Cure (at Room Temperature) 24.0 h - Full Cure (at 60°C) 10.0 min - Heat Stability-Continuous 150.0 °C - Max Heat Stability 1 hour 250.0 °C - Refractive Index Surface approx. 1.34 - - Transparency Clear - - Electrical resistance Yes - - Removable Yes - - Solder-through Repairable Yes - - Dielectric Constant (at 30%RH, 1kHz) 3.0 - -

Technical Details & Test Data

- Concentration vs Thickness

2% Polymer ~ 0.1μm layer 4% Polymer ~ 0.5μm layer 10% Polymer ~ 1.0μm layer - Electrical Properties

Coating Film Thickness Surface Resistance Volume Resistance (Ωm)

0.1 μm film Mayconduct if penetrated* 4 x 10²⁰ 0.5 μm film 1 x 10⁹ 8 x 10²⁰ 1 μm film 5 x 10¹¹ ND Note: The STIRRI HYDRACOAT™ itself is electrically non- conductive and 0.1 μm coat is sufficient to protect from liquids and oils, however nano-coating does not protect from mechanical penetration like flying testing probes.

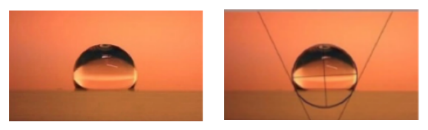

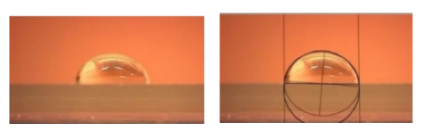

- Contact Angle Analysis

2.0% Polymer concentration on glass

Water contact angle: 113°

Oil contact angle: 82°

Packaging & Availability

Storage & Handling

- Shelf Life

- 2 years

- Shelf Life

For a maximum shelf life of 2 years use controlled storage not exceeding 35°C.