Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- Cleaning Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 91995-81-2

- EC No.

- 295-344-3

- Technologies

- Product Families

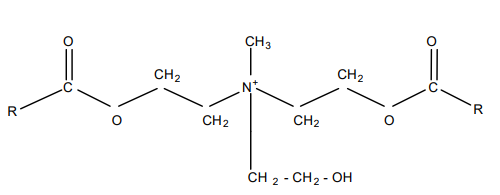

- Chemical Structure

CH₃ OSO₃⁻ R = partially hydrogenated tallow

- Surfactant Type

Cationic.

Features & Benefits

- Labeling Claims

- HII Features

- Industrial Additives Features

- Advantages

Excellent softening without that “greasy feeling”, good antistatic and rewetting properties,do not spoil fabric colors (non yellowing),provide easier ironing and drying.

- Biodegradability

Stepantex VL 90 A complies with the biodegradability criteria as laid down in regulation (EC) No. 648/2004 on detergents.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Applications

STEPANTEX VL 90 A is a cationic surfactant commercially named “Esterquat”. It is ideally suited for the formulation of household and industrial fabric softeners from 3% viscous to 25% fluid active concentrations. STEPANTEX VL90 A can also be used in many other applications such as metal cleaning and polishing compounds, cutting oils, textile auxiliaries, leather conditioners, water repellents, shoe polishes, emulsifiers, paper treatment, clays.

Properties

- Physical Form

- Appearance

- Clear liquid, Beige paste

- Typical Properties

Value Units Test Method / Conditions Cloud Point approx. 33 °C - Color max. 4 - Gardener Scale pH (in 5% in water/IPA (50/50) 3 - - Solids Content 90 wt% - Actives Content 1.04 meq/g - Flash Point 27.5 °C - Isopropanol Content 10 % - Density (at 50°C) 0.96 g/ml - Dynamic viscosity (at 30°C) 2800 mPa.s -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

STEPANTEX VL 90 A is listed in Europe (EINECS 295-344-3), USA (TSCA 157905-74-3), Canada (DSL 157 905-74-3).

- Preservative Compatibility

Although softener formulations based on STEPANTEX VL 90 A generally do not need any protection if produced under ideal conditions, it may be suitable to add preservatives in ready to use or in concentrates that will be diluted by the consumer. Preservatives compatible with cationics and stable and effective at pH between 2,5 and 4,5 should be compatible with STEPANTEX VL 90 A.

Packaging & Availability

Storage & Handling

- Storage & Handling

STEPANTEX VL 90 A should be handled with care and used away from sparks and open flame because it is flammable. Use in a well ventilated area. Contact with the eyes and prolonged contact with the skin should be avoided. Use gloves and safety goggles when handling STEPANTEX VL 90 A.

Drums storage Information

It is recommended that drums of STEPANTEX VL 90 A be stored in sealed containers at temperatures between 4°C and 5 0°C. Avoid heating to temperature higher than 70°C and avoid local overheating. Product must be h eated to 50°C and stirred before use to ensure product is homogeneous before use. The color and odor of STEPANTEX VL 90 A are susceptible to degradation as a result of exposure to high temperature (> 60°C) over extended periods of time (greater than several days), particularly in the presence of air.

Bulk Storage Information

It is recommended that STEPANTEX VL 90 A be stored in stainless steel storage tanks of 316L stainless steel. Tanks should padded with a nitrogen gas blanket and equipped with conservation vent and flame arrestors. Tanks should be adequately insulated to maintain homogeneity, either by a mechanical stirrer or recirculation loop. Bulk storage facilities should be designed to maintain a minimum product temperature of 40°C and a maximum temperature of 55°C. Hot water heating prov ided through 316L stainless steel heating coils is recommended. Low pressure steam heating through coils can be used, but for short period (< 1 hour) and only with adequate agitation to avoid local overheating. 316L stainless steel positive displacement pumps should be used. Piping should be of 316L stainless steel. Rubber hoses lined with Teflon or crosslinked polyethylene and equipped with 316L stainless steel fittings are recommended for loading and unloading. Contact with brass, copper and aluminum components must be strictly avoided.