Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Industrial Additives Functions

- CAS No.

- 55348-40-8

- EC No.

- 611-257-9

- Technologies

- Product Families

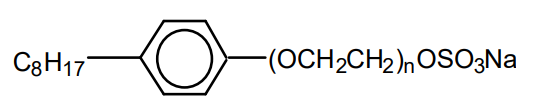

- Chemical Structure

n= 3 , avg

Features & Benefits

- Industrial Additives Features

- Biodegradability

Product is biodegradable.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Applications

POLYSTEP C-OP3S is used in latex manufacture; it aids in the control of latex particle size. It is useful in a variety of polymer systems including vinyl acetate copolymers. POLYSTEP C-OP3S provides mechanical and freeze-thaw stability in latex systems.

Properties

- Physical Form

- Appearance

- White viscous dispersion

- Typical Properties

Value Units Test Method / Conditions pH (in 5% Aqueous) 8 - - Solids Content 20 % - Pour Point 0 °C - Freeze Point -3 °C - Viscosity (at 25°C) 800 cPs - Viscosity (at 60°C) 130 cPs - Flash Point min. 94 °C - Density (at 25°C) 1.06 g/ml - Critical Micelle Concentration (CMC) 218 mg/L - Surface Tension (at CMC) 31 dynes/cm - Regulated Volatile Organic Chemicals (Ethanol) 0 % U.S. EPA

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

All components of POLYSTEP C-OP3S are listed in the following countries: United States (TSCA), Australia (AICS), Canada (DSL), China (IECSC), Europe (Polymer Exempt), Korea (ECL), New Zealand (NZIoC), and Philippines (PICCS).

Packaging & Availability

Storage & Handling

- Storage & Handling

Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling POLYSTEP C-OP3S. Avoid contact with eyes or nose, or prolonged contact with the skin. Wash thoroughly after handling material. It is recommended that POLYSTEP C-OP3S be stored in sealed containers and kept in a cool, dry place. If material is frozen it should be heated gently and stirred to ensure it is homogeneous before use.

Bulk Storage Information

POLYSTEP C-OP3S should be stored in containers made of 316 stainless steel or fiberglass with a corrosion resistant liner. Mild agitation is recommended while storing to maintain homogeneity. Material should be stored between 80 and 90°F. Use mild heat if needed avoiding the use of steam since it may impact product integrity. Recirculated warm water is recommended. Pumps, pipes, and transfer lines should be 316 stainless steel.