Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Product Families

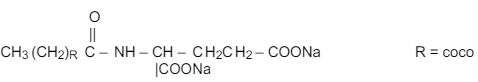

- Chemical Structure

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Format

- Bath & Shower Applications

- Personal Hygiene Applications

- Skin Care Applications

Properties

- Physical Form

- Appearance

- Clear, colorless to pale yellow liquid (at 25°C)

- Typical Properties

Value Units Test Method / Conditions Active Content (MW 327) 25.0 % - pH (as is, at 20°C) 11.5 - - Color (as is) max. 100 APHA - Sodium Chloride Content max. 1 % - Boiling Point min. 100 °C - Freeze Point -1.0 °C - Flash Point min. 94 °C PMCC Viscosity (at 20°C) 10 - 15 cPs - Density (at 20°C) 1.07 g/ml - Specific Gravity (at 20°C) 1.07 - - Viscosity (at 25°C) 17.0 cPs - Preservative None required - -

Safety & Health

- Health Effects

MAPROSYL® 25G-HP is practically nontoxic orally and dermally (LD50 > 2000 mg/kg bw), non-irritating to skin and moderately irritating to eyes when tested as sold.

- Safety Precautions

Normal safety precautions (e.g., gloves and safety goggles) should be employed when handling MAPROSYL® 25G-HP. Contact with eyes, nose or prolonged contact with skin should be avoided. Wash thoroughly after handling MAPROSYL® 25G-HP. See SDS for more information

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace safety practices should be used to control these exposures.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Handling Conditions

Non-Bulk Storage Recommendations: MAPROSYL® 25G-HP should be stored in closed containers and kept in a cool, dry place away from incompatible materials (see Section 10 of the SDS). It is recommended that MAPROSYL® 25G-HP be stored in sealed containers and kept at temperatures between 50°F (10°C) and 120°F (49°C). Avoid overheating or freezing. If material is frozen, mild heat and agitation are recommended to ensure the material is homogeneous before use. If material is frozen it should be heated gently and stirred to ensure it is homogeneous prior to use.