Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Small Cell Size at Low Density.

- Damage Resistant.

- Fire Resistant (Self-Extinguishing).

- Water and Fungus Resistant.

- Excellent Dielectric Properties.

- Good Surface for Bonding.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Applications

SAH has been widely accepted throughout the aerospace industry and several commercial areas as a very tough, environmentally resistant core material in sandwich panels. It has been designed and used in flat and contoured shapes, with a wide variety of facing material and adhesives, and it has extensive service in both structural and non-structural parts.

Properties

- Mechanical Properties

Value Units Test Method / Conditions Compressive Strength (Bare) min. 70 psi - Compressive Strength (Stabilized) min. 85 psi - Plate Shear Strength (L Direction) min. 65 psi - Plate Shear Modulus(L Direction) 3.7 ksi - Plate Shear Strength (W Direction) min. 36 psi - Plate Shear Modulus (W Direction) 2.0 ksi -

Regulatory & Compliance

- Quality Standards

Technical Details & Test Data

- Product Information

Type Designation

SAH is designated as follows:

Material, Cell Size, Density.

Example: SAH 1/8-3.0

Where:

- SAH - Showa Aramid Honeycomb.

- 1/8 - 1/8 inch cell size.

- 3.0 - 3.0 lbs/ft3 Density.

Dimensional Nomenclature

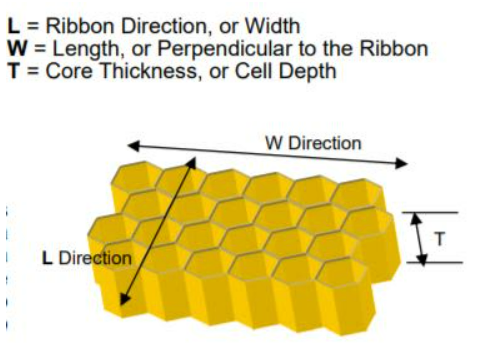

L = Ribbon Direction, or Width

W = Length, or Perpendicular to the Ribbon

T = Core Thickness, or Cell Depth

Special Cell Configuration and Processing

In addition to the hexagonal cell shapes, SAH is available in the OX cell shapes. The OX cell is an over-expanded hexagonal cell that provides a rectangular cell shapes, and provides suitable formability. SAH is also available machined to customer’s requirements, including flat pieces cut to size

Standard Dimensions

SAH is available in the following standard dimensions with the tolerances as indicated.

Cell Configuration L Direction W Direction T Maximum T Minimum Hexagonal Cell 48”±2” 96”±6” 32” 0.125” OX Cell 38”±2” 96”±6 20” 0.125” Tolerances on cut thickness are as follows:

- ±0.006” for 0.120” to 2.000” Thickness

- ±0.010” for 2.001” to 4.000” Thickness

- ±0.120” for 4.001” and over

Note:

1) T maximum and T minimum to be confirmed with Showa Sales Office.

2) Longer L and W directions are available. Please contact Showa Sales Office.

Standard Specifications

Configuration: Tolerance of the cell size will be plus or minus 10 percent of nominal cell size, that is determined by averaging measures of 10 consecutive cell length at 6 random locations. The double cell wall will be permitted providing the density is within the tolerance. The unbounded nodes will be permitted providing the minimum mechanical properties are conformable.

Density: Tolerance of the density will be plus or minus 10 percent of nominal density, that is determined by measuring on a minimum of 18 cubic inch.

- Dimensional Nomenclature