Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- Core Type

- Composite Materials Functions

- CAS No.

- 7429-90-5

- EC No.

- 231-072-3

- Technologies

- Product Families

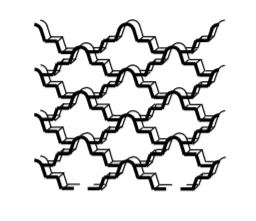

- Structural Appearance

Features & Benefits

- Materials Features

- Features

- Aerospace structural grade honeycomb.

- Superior corrosion protection compared to standard aluminum honeycomb.

- Enhanced bondability and fatigue strength.

- Highest strength and rigidity to weight for sandwich construction.

- Available in 5052 aluminum alloys.

Applications & Uses

- Markets

- Applications

- Composites End Use

- Applications

PAA-SDFH has been developed to enhance the properties of standard aluminum honeycomb against the corrosion. The enhanced corrosion protection of PAA-SDFH can provide a potential to reduce a life cycle cost or/and to reduce manufacturing cost occurred for additional processes to improve corrosion protection and durability of the standard aluminum honeycomb. For this reason, PAA-SDFH will be an alternative for the standard aluminum honeycomb being used for the bonded assemblies of aircrafts.

Properties

- Mechanical Properties

Value Units Test Method / Conditions Density 4.8 pcf - Compressive Strength 872.0 psi - Plate Shear Strength (L Direction) 319.8 psi - Plate Shear Strength (W Direction) 212.6 psi - Plate Shear Modulus (L Direction) 64642.0 psi - Plate Shear Modulus (W Direction) 21902.0 psi -

Technical Details & Test Data

- Product Information

Type Designation

PAA-SDFH is designated as follows:

Material, Alloy, density, Foil Thickness Example: PAA-SDFH 4.8-5052-47

PAA-SDFH:PAA aluminum double flexible honeycomb

- 5052 : 5052 aluminum alloy

- 47: Foil thickness in ten thousandths of an inch

- 4.8:nominal core density in pound per cubic foot

Standard Dimensions

Alloy L Direction W Direction T Minimum 5052 24” +4/-0” 96” +8/-0” 0.200” Tolerances on cut thickness are as follows:

- ±0.005” for 0.120” to 4.000” Thickness

- ±0.062” for 4.001” and over.