Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

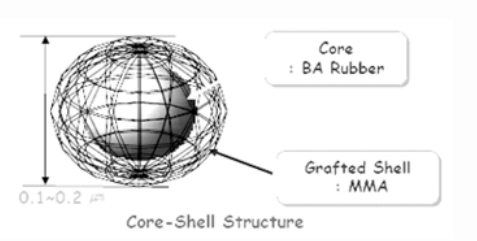

- Core Shell Structure

Features & Benefits

- Materials Features

- The Advantages Of The Product

1. Uniform particle size, low dust

2. Good compatibility with PVC resin powder

3. Excellent long-term weather resistance

4. After use, the final product has a small dimensional change rate and good thermal stability

5. Extremely high impact Strength

6. Good dispersion, not easy to agglomerate

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Application

DL-50 is recommended to produce PVC door and window profiles, PVC doors, PVC guardrails and other PVC outdoor products.

- Suggested Dosage

Add 4.0-6.0 kg per 100 kg of PVC resin powder (specific treatment for specific products).

Properties

- Appearance

- Free flowing white powder

- Mechanical Properties

Value Units Test Method / Conditions Cantilever Impact (23°C Condition) min. 15.0 KJ/m2 GB/T1843 Cantilever Impact (-10°C Condition) min. 15.0 KJ/m2 GB/T1843 Tensile Yield Strength min. 40.0 Mpa GB/T1843 Elongation At Break min. 100.0 % GB/T1040 Cantilever Burst (After 3000 hours Of Aging Treatment) min. 12.0 KJ/m2 GB/T1843 Plasticizing Time 160-190 s - - Typical Properties

Value Units Test Method / Conditions Volatile Matter max. 1.50 % GB/T2914 Apparent Density 0.50±0.60 g/cm3 GB/T1636 Sieve Residue (30 Mesh) max. 2.00 % GB/T2916 Impurity (10x10) max. 20.00 Cm2 GB/T9348 - Comparison table of Plasticization and Mechanical Properties of Dl-50 and Similar Foreign Products

Sample/Project DL-50 FM-21 KM-355 IM-808A Plasticizing time (seconds) 168 160 174 178 Maximum torque (Nm) 36 35.6 35.8 35 Balance torque (Nm) 23.5 23.5 23.6 23.4 Temp @ constant Torque. °C 185 184 185 183 Cantilever rushing in (23℃c condition) 18.6 17.4 18.1 18.9 Cantilever impact (-10°C condition) 11.3 11 11.2 11.5 Tensile Strength 397 393 404 409 Elongation at break 176 160 172 177 Remark The basic formula of the above data:

100 parts of PVC resin powder (K value 67); 2 parts of organotin stabilizer;7 parts for each of the above impact modifiers; 8 parts for light calcium; internal slip DL- 60 0.5 parts; 0.6 parts of external slip agent.

Packaging & Availability

- Packaging Type

- Packaging

25kg/bag of PP outer bag lined with PE inner bag.

Storage & Handling

- Storage

- Product should be stored in a cool and dry environment.

- The limited period of the product is tentatively set at 2 years. After the expiration date, it can continue to be used after passing the test.