Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Ultem Resin Attributes for Eyewear Frames

- Super tough

- Meets JIS B7285, includes 20,000 cycles blending repetitions

- Long life cycle

- UV stabilized

- Light weight

- Excellent in chemical and hydrolytic resistance

- Excellent dimensional stability

- Thin wall molding down to 1.2 mm

- Long term heat resistance (RTI > 170°C)

- Available in custom colors

ULTEM resin delivers a broad range of desirable performance properties for eyeglass frames and is also potentially usable in safety and 3D eyewear frames.

Dimensional and Hydrolytic Stability

- Ensures the lenses are retained in the frame

- Extends the product life cycle

Temperature and Chemical Resistance

- Excellent stain and chemical resistance

- High heat deflection temperature protects the frames even when left on the car dashboard in direct sunlight

Design Freedom & Ease of Production

- Precision thin wall molding at 1.2 mm

- Capability for custom colors providing a wide range of esthetic effects

- Enhanced processing window vs. nylons

Density

- Intrinsically lightweight (up to 50% vs. metal)

Mechanical Properties

- Higher flexural modulus at 3510MPa

- Offers elasticity coupled with resistance to deformation, allowing the frame to bend easily yet return to its original shape

- ULTEM™ Resin Offers

- Lead times of approximately 4 weeks*

- Up to 55% higher stiffness

- Better dimensional stability vs. PSU

- Excellent property retention at elevated temps:

Tg - 217°C, HDT @ 1.80 MPa: 190°C

- Up to 17% lower CTE than PES/PPSU

- Chemical resistance

- Metal plating compatibility

- Compatibility with multiple sterilization methods

- Availability for stock shapes & films

- Product Highlight

The ULTEM™ family of amorphous thermoplastic polyetherimide (PEI) resins offer outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance. ULTEM™ copolymers are also available for even higher heat, chemical and elasticity needs.

ULTEM™ resins uniquely balance both mechanical properties and processability, offering design engineers exceptional flexibility and freedom. ULTEM™ resins are also inherently flame retardant and possess excellent dielectric character. ULTEM™ resins are therefore an excellent candidate for your electric vehicle battery needs where high heat resistance is required.

With its appreciable flow and dimensional stability, coupled with excellent resistance to Li-ion electrolyte, ULTEM™ resins such as ULTEM™ CRS5011 resin are today being used for insulation of Li-ion cell terminals. Given its excellent dielectric character, ULTEM™ resin is also an ideal candidate for bus bar insulation. For other powertrain elements, such as DC power converters. ULTEM™ UTF120 dielectric film is already enabling high temperature film capacitors.

- Key Benefits

- Heat Resistance

- Dimensional Stability

- Dielectric Performance

- Miniaturization and Thin Wall

- Resilience

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

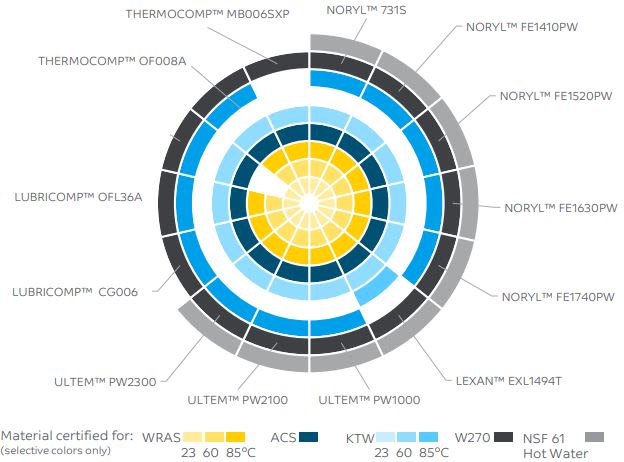

- Resins and Compounds for Water Management Applications

SABIC’S specialty resins and compounds offer the water management industry design flexibility to produce products with longer lives and higher quality. Our materials are excellent candidates to replace metal and can provide weight reduction, corrosion resistance, high strength and stiffness or inherent lubricity depending on the application’s requirements.

- Excellent strength performance.

- Excellent abrasion performance.

In addition to mechanical requirements, applications for the water management industry need certification for potable water compliance according to national standards. SABIC has developed a dedicated potable water certified portfolio to help our customers accelerate their application development time to market.

SABIC Offerings Certified for Water Management Applications:

For applications that do not require potable water certification, SABIC’s Specialties portfolio includes a wide range of specialized thermoplastic compounds based on different base resins and fillers.

Properties

- Color

- Flame Rating

- Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.51 g/cm³ ISO 1183 Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ 0.1 % ISO 62-4 Moisture Absorption (at 23°C, 50% RH, Equilibrium) ¹¹ 0.6 % ISO 62-4 Water Absorption (at 23°C, 24hrs) ¹¹ 0.16 % ASTM D570 Water Absorption (at 23°C, 24hrs) ¹¹ 0.16 % ISO 62-1 Water Absorption (at 23°C, saturated) ¹¹ 0.9 % ASTM D570 Water Absorption (at 23°C, saturated) ¹¹ 9.00E-01 % ISO 62-1 Melt Volume Rate (at 360°C, 5.0 kg) ¹¹ 6 cm³/10 min ISO 1133 Specific Gravity ¹¹ 1.51 - ASTM D792 Melt Flow Rate (at 337°C, 6.6 kgf) ¹¹ 5 g/10 min ASTM D1238 Mold Shrinkage (flow, 3.2 mm) ¹¹ 0.2 - 0.4 % SABIC method - Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Break, 5 mm/min) ¹¹ 175 MPa ISO 527 Tensile Strain (Break, 5 mm/min) ¹¹ 2.4 % ISO 527 Tensile Modulus (at 1 mm/min) ¹¹ 10500 MPa ISO 527 Flexural Stress (Break, 2 mm/min) ¹¹ 240 MPa ISO 178 Flexural Modulus (at 2 mm/min) ¹¹ 9600 MPa ISO 178 Ball Indentation Hardness (H358/30) ¹¹ 165 MPa ISO 2039-1 Hardness (Rockwell M) ¹¹ 110 - ISO 2039-2 Hardness (Rockwell M) ¹¹ 114 - ASTM D785 Taber Abrasion (CS-17, 1 kg) ¹¹ 20 mg/1000cy SABIC method Tensile Stress (Break, Type I, 5 mm/min) ¹¹ 175 MPa ASTM D638 Tensile Strain (Break, Type I, 5 mm/min) ¹¹ 2.5 % ASTM D638 Tensile Modulus (at 5 mm/min) ¹¹ 10400 MPa ASTM D638 Flexural Stress (Break, 2.6 mm/min, 100 mm span) ¹¹ 230 MPa ASTM D790 Flexural Modulus (at 2.6 mm/min, 100 mm span) ¹¹ 9400 MPa ASTM D790 Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ 250 MPa ASTM D790 Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ 9700 MPa ASTM D790 - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 215 °C ISO 75/Bf Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 210 °C ISO 75/Af Vicat Softening Temperature (Rate A/50) ¹¹ 225 °C ISO 306 Vicat Softening Temperature (Rate B/120) ¹¹ 220 °C ISO 306 Vicat Softening Temperature (Rate B/50) ¹¹ 213 °C ISO 306 Coefficient of Thermal Expansion (at -40°C to 150°C, flow) ¹¹ 0.000018 1/°C ISO 11359-2 Coefficient of Thermal Expansion (at -40°C to 150°C, xflow) ¹¹ 0.000048 1/°C ISO 11359-2 Thermal Conductivity ¹¹ 0.31 W/m-°C ISO 8302 Ball Pressure Test (at 123°C to 127°C) ¹¹ Pass - IEC 60695-10-2 Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ 215 °C ASTM D648 Heat Deflection Temperature (at 0.45 MPa, 6.4 mm, Unannealed) ¹¹ 212 °C ASTM D648 Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ 211 °C ASTM D648 Heat Deflection Temperature (at 1.82 MPa, 6.4 mm, Unannealed) ¹¹ 210 °C ASTM D648 Coefficient of Thermal Expansion (at -20°C to 150°C, flow) ¹¹ 0.000018 1/°C ASTM E831 Coefficient of Thermal Expansion (at -20°C to 150°C, xflow) ¹¹ 0.000048 1/°C ASTM E831 Relative Temperature Index (Electrical) ᵖ ¹¹ 180 °C UL 746B Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ 170 °C UL 746B Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ 180 °C UL 746B - Electrical Properties

Value Units Test Method / Conditions Comparative Tracking Index (UL, PLC) ᵖ ¹¹ 4 PLC Code UL 746A Hot Wire Ignition (PLC 1) ᵖ ¹¹ min. 3 mm UL 746A Hot Wire Ignition (PLC 3) ᵖ ¹¹ min. 1.5 mm UL 746A High Ampere Arc Ignition (PLC 3) ᵖ ¹¹ min. 1.5 mm UL 746A High Ampere Arc Ignition (PLC 4) ᵖ ¹¹ min. 3 mm UL 746A High Voltage Arc Track Rate (PLC) ᵖ ¹¹ 3 PLC Code UL 746A Arc Resistance (Tungsten, PLC) ᵖ ¹¹ 6 PLC Code ASTM D495 - Impact Properties

Value Units Test Method / Conditions Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ 10 kJ/m² ISO 180/1A Izod Impact (Notched, 80*10*4, at -30°C) ¹¹ 10 kJ/m² ISO 180/1A Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ 40 kJ/m² ISO 180/1U Izod Impact (Unnotched, 80*10*4, at -30°C) ¹¹ 40 kJ/m² ISO 180/1U Charpy Impact (at 23°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ 10 kJ/m² ISO 179/1eA Charpy Impact (at -30°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ 1.00E+01 kJ/m² ISO 179/1eA Charpy Impact (at 23°C, Unnotch Edgew 80*10*4 sp=62mm) ¹¹ 40 kJ/m² ISO 179/1eU Charpy Impact (at -30°C, Unnotch Edgew 80*10*4 sp=62mm) ¹¹ 40 kJ/m² ISO 179/1eU Izod Impact (Notched, at 23°C) ¹¹ 90 J/m ASTM D256 Izod Impact (Notched, at -30°C) ¹¹ 80 J/m ASTM D256 Izod Impact (Reverse Notched, 3.2 mm) ¹¹ 470 J/m ASTM D256 Izod Impact (Unnotched, at 23°C) ¹¹ 600 J/m ASTM D4812 Izod Impact (Unnotched, at -30°C) ¹¹ 600 J/m ASTM D4812 - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 150 °C - Drying Time ⁷ 4 - 6 Hrs - Drying Time (Cumulative) ⁷ 24 Hrs - Maximum Moisture Content ⁷ 0.02 % - Melt Temperature ⁷ 350 - 410 °C - Nozzle Temperature ⁷ 345 - 410 °C - Front - Zone 3 Temperature ⁷ 345 - 420 °C - Middle - Zone 2 Temperature ⁷ 340 - 410 °C - Rear - Zone 1 Temperature ⁷ 330 - 400 °C - Hopper Temperature ⁷ 80 - 120 °C - Mold Temperature ⁷ 135 - 180 °C - Shot to Cylinder Size ⁷ 40 - 60 % - Vent Depth ⁷ 0.025 - 0.076 mm - Screw Speed ⁷ 40 - 70 rpm - Screw Speed (Circumferential speed) ⁷ 0.15 - 0.25 m/s - Back Pressure ⁷ 0.3 - 1.5 MPa - - Flame Characteristics

Value Units Test Method / Conditions UL Recognized (94-5VA Flame Class Rating) ᵖ min. 1.2 mm UL 94 UL Recognized (94V-0 Flame Class Rating) ᵖ min. 0.25 mm UL 94 Glow Wire Ignitability Temperature (at 2.0 mm) ᵖ 900 °C IEC 60695-2-13 Glow Wire Flammability Index (at 2 mm) ᵖ 960 °C IEC 60695-2-12 Oxygen Index (LOI) ᵖ 50 % ASTM D2863 Oxygen Index (LOI) ᵖ 48 % ISO 4589 - Note

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

Regulatory & Compliance

- Certifications & Compliance

- ULTEM™ Resin May Support

- Electrical: UL94 V0 & 5VA, UL94 F1, UL746B

- Telecom: Telcordia GR-326, TIA/EIA-604-10A

- Mobility: FMVSS, IATF 16949, ISO 14001

- Food Service: FDA, NSF, EFSA, JHOSPA

- Water: NSF, WRAS, KTW

- Semiconductors: FM

- Healthcare: ISO 10993, FDA, USP Class VI, compatible with multiple sterilization methods

- Aerospace: ABD 0031, BMS, FAR25.853, OSU 55/55 & NBS smoke density tests

Packaging & Availability

- Regional Availability

- Availability

ULTEM™ resin is available in transparent and opaque custom colors, and can be glass filled for added stiffness.