Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Performance Advantages

- Weight reduction : Low specific gravity of -1.67, ~40% lighter than aluminum

- Low temperature drift : Low CTE in broad range of temperature - close to aluminum

- Low insertion loss : Easy plating with low Ra and excellent adhesion to metal

- Low signal loss : Stable and low Dk/Df under different frequencies

- Part integration : Injection molding supports new designs and ease of assembly

- SMT compatible : Heat resistance up to 260°C for SMT assembly

- Reduced production cycle time : Good flowability and low warpage

- Product Highlights

ULTEM 3473 resin is 40% lighter than aluminum and a potential alternative for these RF filters thanks to its low CTE, Surface Mount Technology (SMT) process compatibility and excellent surface metallization performance.

Integrated Antenna Filter Units

ULTEM 3473 resin can also support the design of new integrated antenna filter units (AFUs), which cannot be achieved with metal. Using injection molding, the dipole antenna matrix and RF cavity filter body can be produced as one component. This approach simplifies production and may lead to cost reductions and additional weight savings.

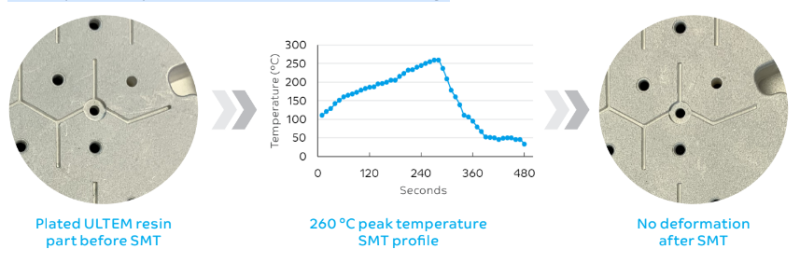

Ultem 3473 Resin is Compatible With SMT Technology

Thanks to improved Heat Deflection Temperature (HDT), ULTEM 3473 resin can withstand the 260°C peak temperatures in solder mount assembly.

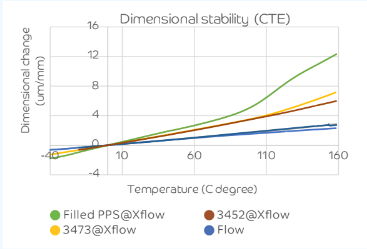

Coefficient of Thermal Expansion (ISO 11359-2)

Cross flow improvement over glass filled PPS for improved dimensional stability

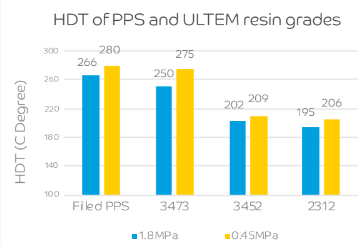

Improved Heat Deflection Temperature (ISO 75)

ULTEM 3473 resin has a HDT close to glass filled PPS

Potential For Metal Replacement Using Ultem™ Resin

ULTEM resins have excellent surface metallization performance and are compatible with mainstream plating processes. An excellent candidate for 5G networking components, ULTEM resins can also be considered for use in other industries where metal replacement is desired. ULTEM resins can be used in metalization processes like electroless plating, electro- plating and physical vapor deposition (PVD).

To address varying product and processing requirements, multiple ULTEM resin grades are available in the portfolio and can be considered for metal replacement. Each of these grades show an excellent adhesion to metal, low surface roughness and great resistance to blistering and delamination after exposure to thermal shocks and long periods of humidity.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.68 g/cm³ ISO 1183 Melt Volume Rate (at 320°C, 5.0 kg) ¹¹ 5.5 cm³/10 min ISO 1133 Mold Shrinkage (flow) ᵍ ¹¹ 0.2 - 0.3 % SABIC method Mold Shrinkage (xflow) ᵍ ¹¹ 0.3 - 0.4 % SABIC method - Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Break, Type I, 5 mm/min) ¹¹ 156 MPa ASTM D638 Tensile Strain (Break, Type I, 5 mm/min) ¹¹ 1.8 % ASTM D638 Tensile Modulus (at 5 mm/min) ¹¹ 15800 MPa ASTM D638 Flexural Strength (at 1.3 mm/min, 50 mm span) ¹¹ 231 MPa ASTM D790 Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ 14500 MPa ASTM D790 Tensile Stress (Break, 5 mm/min) ¹¹ 146 MPa ISO 527 Tensile Strain (Break, 5 mm/min) ¹¹ 1.65 % ISO 527 Tensile Modulus (at 1 mm/min) ¹¹ 15900 MPa ISO 527 Flexural Strength (at 2 mm/min) ¹¹ 201 MPa ISO 178 Flexural Modulus (at 2 mm/min) ¹¹ 14500 MPa ISO 178 - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ 275 °C ASTM D648 Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ 249 °C ASTM D648 Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 275 °C ISO 75/Bf Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 250 °C ISO 75/Af Coefficient of Thermal Expansion (at -40°C to 150°C, flow, tested on plaques) ¹¹ 0.000019 1/°C ISO 11359-2 Coefficient of Thermal Expansion (at -40°C to 150°C, xflow, tested on plaques) ¹¹ 0.000025 1/°C ISO 11359-2 - Electrical Properties

Value Units Test Method / Conditions Dielectric Constant (at 1.9 GHz) ¹¹ 4.25 - SABIC method Dissipation Factor (at 1.9 GHz) ¹¹ 0.0056 - SABIC method Dielectric Constant (at 5 GHz) ¹¹ 4.2 - SABIC method Dissipation Factor (at 5 GHz) ¹¹ 0.0063 - SABIC method - Impact Properties

Value Units Test Method / Conditions Izod Impact (Notched, at 23°C) ¹¹ 56 J/m ASTM D256 Izod Impact (Unnotched, at 23°C) ¹¹ 390 J/m ASTM D4812 Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ 6.5 kJ/m² ISO 180/1A Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ 17.3 kJ/m² ISO 180/1U - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 150 °C - Drying Time ⁷ 4 - 6 Hrs - Drying Time (Cumulative) ⁷ 24 Hrs - Maximum Moisture Content ⁷ 0.02 % - Melt Temperature ⁷ 315 - 335 °C - Nozzle Temperature ⁷ 300 - 335 °C - Front - Zone 3 Temperature ⁷ 290 - 335 °C - Middle - Zone 2 Temperature ⁷ 280 - 325 °C - Rear - Zone 1 Temperature ⁷ 270 - 315 °C - Mold Temperature ⁷ 120 - 180 °C - Back Pressure ⁷ 0.3 - 0.7 MPa - Screw Speed ⁷ 40 - 70 rpm - - Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Regional Availability