Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

- Precision Components - ULTEM 2x20 resin’s dimensional stability and high melt flow can enable the tight tolerances required to design and manufacture the latest precision components.

- High Strength - ULTEM 2x20 resin’s high mechanical performance makes it an excellent candidate for strong thin-walled assemblies.

- Complex Designs - ULTEM 2x20 resins are well-suited for molding into a variety of complex geometries providing the opportunity to consolidate parts to help lower system costs.

- Long In-Service Life - ULTEM 2x20 resin’s low coefficient of thermal expansion (CTE) and high temperature resistance support long-term in-service life.

- Potential Material Advantages and Benefits

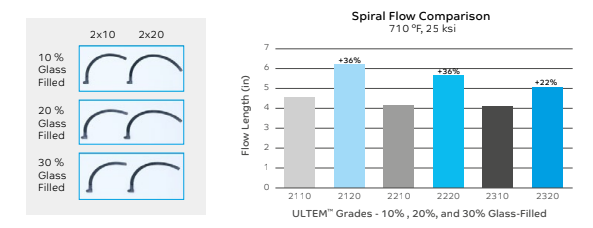

ULTEM 2120, 2220 and 2230 resins were developed following customer needs across multiple industries to enhance part design, colorability, durability and production costs.

- High Flow for Complex Precision Components - ULTEM 2120, 2220, and 2320 resins exhibit exceptional flow characteristics. The lower viscosity materials enable smaller, more-complex, and thinner walled components.

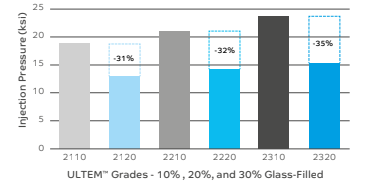

- Save Processing Time and Production Costs - ULTEM 2120, 2220, and 2320 resins process at lower injection pressures. This can enable more flexible design and save processing time and cost.

- Injection pressures drop up to 35% helping enable thin wall designs and processing flexibility

- Ability to reduce cooling time up to 10% -> potential to increase productivity and reduce part cost

Figure: Injection Pressure Comparison - 710°F Melt, 350°F Mold

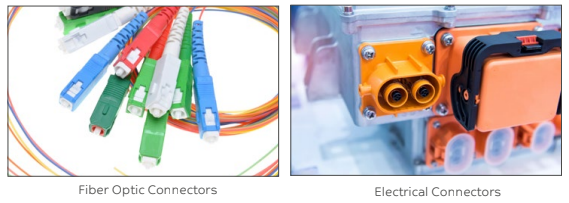

- Colorability for Customization and Identification - The ULTEM 2x20 resin series can be colored for easy customization and identification.

Some potential benefits:

- Easy part identification

- Component customization

- Extraordinary colors for your brand

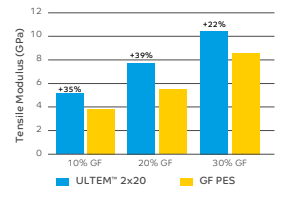

- High Mechanical Strength for Durability and Reliability - ULTEM 2120, 2220, and 2320 resins have excellent mechanical properties, enabling durable, high-strength parts.

Figure: Tensile Modulus (ASTM D638)

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Flame Rating

- Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.4 g/cm³ ISO 1183 Melt Flow Rate (at 337°C, 6.7 kgf) ¹¹ 14 g/10 min ASTM D1238 Melt Volume Rate (at 337°C, 6.7 kg) ¹¹ 8 cm³/10 min ISO 1133 Mold Shrinkage (flow) ᶠ ¹¹ 0.3 - 0.5 % SABIC method Mold Shrinkage (xflow) ᶠ ¹¹ 0.3 - 0.5 % SABIC method Specific Gravity ¹¹ 1.4 - ASTM D792 - Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Yield, 5 mm/min) ¹¹ 150 MPa ISO 527 Tensile Stress (Break, 5 mm/min) ¹¹ 148 MPa ISO 527 Tensile Strain (Yield, 5 mm/min) ¹¹ 3.7 % ISO 527 Tensile Strain (Break, 5 mm/min) ¹¹ 3.9 % ISO 527 Tensile Modulus (at 1 mm/min) ¹¹ 6800 MPa ISO 527 Flexural Modulus (at 2 mm/min) ¹¹ 7000 MPa ISO 178 Flexural Stress (Break, 2 mm/min) ¹¹ 240 MPa ISO 178 Tensile Modulus (at 5 mm/min) ¹¹ 7700 MPa ASTM D638 Tensile Strain (Break, Type I, 5 mm/min) ¹¹ 3.3 % ASTM D638 Tensile Stress (Break, Type I, 5 mm/min) ¹¹ 160 MPa ASTM D638 Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ 7600 MPa ASTM D790 Flexural Stress (Yield, 1.3 mm/min, 50 mm span) ¹¹ 250 MPa ASTM D790 Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ 250 MPa ASTM D790 - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 210 °C ISO 75/Af Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ 210 °C ASTM D648 Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 215 °C ISO 75/Bf Vicat Softening Temperature (Rate B/120) ¹¹ 225 °C ISO 306 Vicat Softening Temperature (Rate B/50) ¹¹ 220 °C ASTM D1525 Coefficient of Thermal Expansion (at -40°C to 40°C, flow) ¹¹ 0.000016 1/°C ASTM E831 Coefficient of Thermal Expansion (at -40°C to 40°C, xflow) ¹¹ 0.0000534 1/°C ASTM E831 Relative Temperature Index (Electrical) ¹¹ 170 °C UL 746B Relative Temperature Index (Mechanical with impact) ¹¹ 170 °C UL 746B Relative Temperature Index (Mechanical without impact) ¹¹ 170 °C UL 746B - Electrical Properties

Value Units Test Method / Conditions Hot Wire Ignition (PLC 2) ¹¹ min. 0.5 mm UL 746A Hot Wire Ignition (PLC 1) ¹¹ min. 1.5 mm UL 746A High Ampere Arc Ignition (PLC 0) ¹¹ 0.5 mm UL 746A High Voltage Arc Track Rate (PLC) ¹¹ 3 PLC Code UL 746A Volume Resistivity ¹¹ 1.00E+13 Ω.cm ASTM D257 Dielectric Strength (in air, at 1.6mm) ¹¹ 27 kV/mm ASTM D149 Dielectric Strength (in oil, at 1.6mm) ¹¹ 27 kV/mm ASTM D149 Comparative Tracking Index (UL, PLC) ¹¹ 4 PLC Code UL 746A - Impact Properties

Value Units Test Method / Conditions Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ 6 kJ/m² ISO 180/1A Izod Impact (Notched, 80*10*4, at -30°C) ¹¹ 6 kJ/m² ISO 180/1A Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ 34 kJ/m² ISO 180/1U Izod Impact (Unnotched, 80*10*4, at -30°C) ¹¹ 34 kJ/m² ISO 180/1U Charpy Impact (at 23°C, V-notch Edgew 80*10*3 sp=62mm) ¹¹ 4 kJ/m² ISO 179/1eA Charpy Impact (at -30°C, V-notch Edgew 80*10*4 sp=62mm) ¹¹ 4 kJ/m² ISO 179/1eA Charpy Impact (at 23°C, Unnotch Edgew 80*10*4 sp=62mm) ¹¹ 39 kJ/m² ISO 179/1eU Charpy Impact (at -30°C, Unnotch Edgew 80*10*4 sp=62mm) ¹¹ 39 kJ/m² ISO 179/1eU Izod Impact (Notched, at 23°C) ¹¹ 60 J/m ASTM D256 Izod Impact (Notched, at -30°C) ¹¹ 55 J/m ASTM D256 Izod Impact (Unnotched, at 23°C) ¹¹ 580 J/m ASTM D4812 - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 150 °C - Drying Time ⁷ 4 - 6 Hrs - Drying Time (Cumulative) ⁷ 24 Hrs - Maximum Moisture Content ⁷ 0.02 % - Melt Temperature ⁷ 350 - 400 °C - Nozzle Temperature ⁷ 345 - 400 °C - Front - Zone 3 Temperature ⁷ 345 - 400 °C - Middle - Zone 2 Temperature ⁷ 340 - 400 °C - Rear - Zone 1 Temperature ⁷ 330 - 400 °C - Mold Temperature ⁷ 135 - 165 °C - Back Pressure ⁷ 0.3 - 0.7 MPa - Screw Speed ⁷ 40 - 70 rpm - Shot to Cylinder Size ⁷ 40 - 60 % - Vent Depth ⁷ 0.025 - 0.076 mm - - Flame Characteristics

Value Units Test Method / Conditions UL Recognized (94V-0 Flame Class Rating) ᵖ min. 0.5 mm UL 94 Glow Wire Ignitability Temperature (at 3.0 mm) ᵖ 825 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 1.5 mm) ᵖ 825 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 0.5 mm) ᵖ 825 °C IEC 60695-2-13 Glow Wire Flammability Index (at 3 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 1.5 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 0.5 mm) ᵖ 960 °C IEC 60695-2-12 - Note

- ᶠ Measurement meets requirements as specified in ASTM D4496

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Regional Availability