Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Base Chemicals Functions

- CASE Ingredients Functions

- Technologies

- Product Families

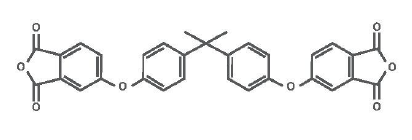

- Chemical Structure

Bisphenol-A Dianhydride, BisDA

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- CASE Ingredients Features

- Materials Features

- Benefits of BISDA

BISDA (BPA based dianhydride) has excellent thermal properties that may be used as a co-monomer in Polyimide synthesis or as a curing agent in epoxy thermoset systems. BISDA is provided as a flake and is soluble in the typical organic solvents used in polyimide varnishes, coatings, adhesives, films and wire enamels. Incorporating BISDA into polyimide formulations may provide enhanced performance in: heat resistance, flexibility/softness, dimensional stability and metal adhesion properties. In epoxy systems, BISDA as a curing agent may offer improved thermal performance, increased pot life, easier handling, improved chemical resistance, better toughness, lower dielectric properties, lower shrinkage and lower moisture absorption.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Base Chemicals End Uses

- Coating Type

- Plastics & Elastomers End Uses

- Processing Guidelines

- Add BISDA into MTHPA

Scale 120 - 130 gms

- BISDA content: 6 - 20 wt%

- Mixing temperature: 22°C

- Time: 3 minutes

Observations: Turbid solutions.

2. Heat mixture at 120°C

BISDA content Vs heating time

- 6.7 wt% >>> 15 min

- 13.1 wt% >>> 20 min

- 19.2 wt% >>> 30 min

Observation: Clear Solutions

3. Cool down 80°C and add D.E.R 332

Scale: 275-285 gms

- Anhydride to epoxy ratio: 0.8

- Mixing temperature: 80°C

- Time: 3 min

Observations: Clear Solution

4. Add catalyst 2E-4MI at 80°C

Scale: 275-285 gms

- 2E-4MI content: wt%

- Mixing temperature: 80°C

- Time: 2 min

Observation: Clear Solutions

5. Pour into a pre heated mold

Scale: 275-285 gms

- Mold Temperature: 130°C

- Pouring Time: 2 - 3 min

6. Thermal Curing

Curing Profile

- 80°C >> 30 min

- 120°C >> 30 min

- 150°C >> 30 min

- 180°C >> 60 min

Properties

Technical Details & Test Data

- Achieving High Heat Epoxy Formulations Using BISDA

BISDA loading (wt%) in overall formulation

Unit 0% 6.70% 13.10% 19.20% Thermal Performance Tg by DMA °C 145 164 173 182 Viscosity of BISDA MTHPA blends

Dynamic Viscosity @ 25°C cP 400 1100 3000 8000 Dynamic Viscosity @ 90°C cP 38 42 48 80 Formulations: Epoxy: D.E.R.(TM) 332* phr 100 100 100 100 MTHPA** phr 78.1 70.3 62.5 54.7 BISDA** phr 0 12.2 24.5 36.7 2E 4 MI*** phr 1.8 1.8 1.9 1.9 * Anhydride to Epoxy (A/E) ratio: 0.8

** Anhydride BISDA 1000 /(Anhydride MTHPA + Anhydride BISDA 1000 )): 0, 0.1, 0.2 and 0.3

*** Catalyst content: 1 wt % of total formulation

Packaging & Availability

- Country Availability

- Regional Availability