Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

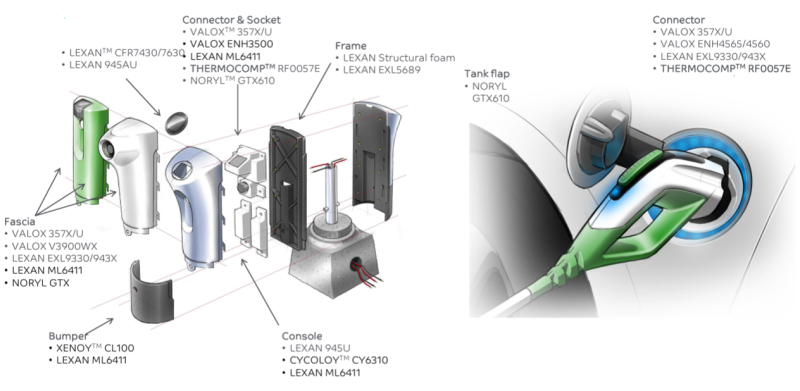

- SABIC Solution for EVSE

EV supply equipment (EVSE)

EV supply equipment include conductors, such as the phase, neutral and protective earth conductors, the EV couplers, attachment plugs, and other accessories, devices, power outlets or apparatuses installed specifically for the purpose of delivering energy from the premises wiring to the EV and allowing communication between them if required. SABIC has a wide range of resins and other material choices listed below that may be suitable for this application, and we can help customers to comply with Europe / US / APAC regulations and bring extra value to customers.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.39 g/cm³ ISO 1183 Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ 0.15 - 0.4 % ISO 294 Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ 1 - 1.2 % ISO 294 Water Absorption (at 23°C, 24hrs) ¹¹ 2.64 % ISO 62-1 - Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Break, 5 mm/min) ¹¹ 130 MPa ISO 527 Tensile Strain (Break, 5 mm/min) ¹¹ 2.4 % ISO 527 Tensile Modulus (at 1 mm/min) ¹¹ 9400 MPa ISO 527 Flexural Stress (Yield, at 2 mm/min) ¹¹ 190 MPa ISO 178 Flexural Modulus (at 2 mm/min) ¹¹ 8000 MPa ISO 178 - Thermal Properties

Value Units Test Method / Conditions Ball Pressure Test (approximate maximum) ¹¹ 240 °C IEC 60695-10-2 Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 240 °C ISO 75/Af Relative Temperature Index (Electrical) ᵖ ¹¹ 140 °C UL 746B Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ 110 °C UL 746B Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ 140 °C UL 746B - Electrical Properties

Value Units Test Method / Conditions Volume Resistivity ¹¹ 1.00E+12 Ω.cm ASTM D257 Dielectric Strength (in air, at 1.6mm) ¹¹ 16 kV/mm ASTM D149 Comparative Tracking Index ¹¹ 600 V IEC 60112 Comparative Tracking Index (UL, PLC) ¹¹ 0 PLC Code UL 746A Hot Wire Ignition (PLC 0) ¹¹ min. 0.4 mm UL 746A High Ampere Arc Ignition (PLC 0) ¹¹ min. 0.4 mm UL 746A High Voltage Arc Track Rate (PLC) ¹¹ 0 PLC Code UL 746A - Impact Properties

Value Units Test Method / Conditions Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ 45 kJ/m² ISO 180/1U Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ 7 kJ/m² ISO 180/1A - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 80 °C - Drying Time ⁷ 4 Hrs - Maximum Moisture Content ⁷ 0.15 - 0.25 % - Melt Temperature ⁷ 265 - 275 °C - Front - Zone 3 Temperature ⁷ 260 - 270 °C - Middle - Zone 2 Temperature ⁷ 255 - 265 °C - Rear - Zone 1 Temperature ⁷ 250 - 260 °C - Mold Temperature ⁷ 60 - 100 °C - Back Pressure ⁷ 0.2 - 0.3 MPa - Screw Speed ⁷ 30 - 60 rpm - - Flame Characteristics

Value Units Test Method / Conditions UL Recognized (94-5VA Flame Class Rating) ᵖ min. 0.9 mm UL 94 UL Recognized (94-5VB Flame Class Rating) ᵖ min. 1.5 mm UL 94 UL Recognized (94V-0 Flame Class Rating) ᵖ min. 0.4 mm UL 94 UV-light (Water exposure/immersion) ᵖ F1 - UL 746C Glow Wire Ignitability Temperature (at 3.0 mm) ᵖ 825 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 2.0 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 1.6 mm) ᵖ 7.75E+02 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 1.5 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 1.0 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 0.9 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 0.8 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Ignitability Temperature (at 0.4 mm) ᵖ 775 °C IEC 60695-2-13 Glow Wire Flammability Index (at 3 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 2 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 1.6 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 1.5 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 0.9 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 0.8 mm) ᵖ 960 °C IEC 60695-2-12 Glow Wire Flammability Index (at 0.4 mm) ᵖ 960 °C IEC 60695-2-12 - Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability