Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

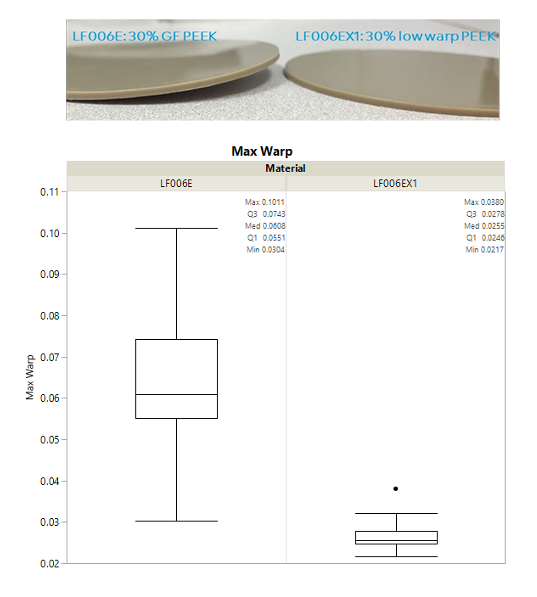

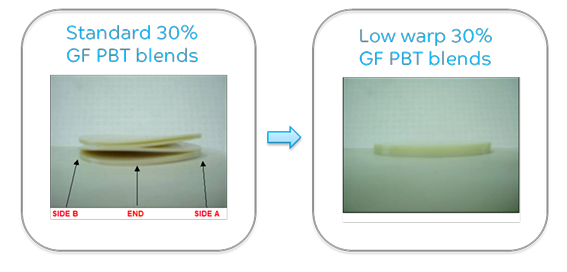

- LNP™ Novel Low Warp Products

Issue Statement

Warpage and lack of dimensional stability often observed at short glass filled products.

LNP Low Warp Technology

Utilize a new technology to improve warpage and dimensional stability, which now is applied to various base resins.Value Propositions

- Improved dimensional stability

- Similar/improved mechanical property

- Reduced CTE

- Reduced potential secondary processing

- Circular economy-focused solutions available for PCR PC, iQ PBT based resins

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Yield, Type I, 5 mm/min) ¹¹ 150 MPa ASTM D638 Tensile Strain (Break, Type I, 5 mm/min) ¹¹ 3.5 % ASTM D638 Tensile Modulus (at 5 mm/min) ¹¹ 7040 MPa ASTM D638 Flexural Stress (Yield, 1.3 mm/min, 50 mm span) ¹¹ 240 MPa ASTM D790 Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ 7030 MPa ASTM D790 - Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.42 g/cm³ ASTM D792 Melt Flow Rate (at 337°C, 6.7 kgf) ¹¹ 9.5 g/10 min ASTM D1238 - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ 210 °C ASTM D648 Relative Temperature Index (Electrical) ᵖ ¹¹ 105 °C UL 746B Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ 105 °C UL 746B Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ 105 °C UL 746B - Impact Properties

Value Units Test Method / Conditions Izod Impact (Notched, at 23°C) ¹¹ 60 J/m ASTM D256 - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 150 °C - Drying Time ⁷ 4 - 6 Hrs - Melt Temperature ⁷ 360 - 400 °C - Rear - Zone 1 Temperature ⁷ 360 - 380 °C - Middle - Zone 2 Temperature ⁷ 370 - 390 °C - Front - Zone 3 Temperature ⁷ 380 - 400 °C - Nozzle Temperature ⁷ 390 - 400 °C - Mold Temperature ⁷ 140 - 180 °C - Back Pressure ⁷ 0.3 - 0.7 MPa - Screw Speed (Circumferential speed) ⁷ 0.2 - 0.3 m/s - Vent Depth ⁷ 0.025 - 0.076 mm - - Flame Characteristics

Value Units Test Method / Conditions UL Recognized (94V-0 Flame Class Rating) ᵖ min. 0.75 mm UL 94 UL Recognized (94V-2 Flame Class Rating) ᵖ min. 0.4 mm UL 94 - Note

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability