Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Wear and Friction Solutions Automotive Under-the-hood (UTH)

Current engineering demands in automotive power train applications emphasize reliability, efficiency, and light-weighting, but not with disregard of system cost. The application of thermoplastic solutions in gears, bearings, bushings and other moving parts is a recognized opportunity to provide high performance solutions that in the end save money.

High Temperature Demands

Applications like transmission seal rings, throttle body gears and other UTH actuators must operate at high temperatures, often under high loads and speeds, while exposed to automotive fluids. The expectation of reliability and safety put significant demands on the performance and life of these parts

Internally Lubricated Compounds

The addition of an internal lubricant to a thermoplastic material can help improve the wear resistance and reduce the coefficient of friction in plastic parts. Traditional lubricants like PTFE and PTFE/Si blends are common. The use of high temperature thermoplastic resins like PEEK, PPS and PPA can give performance at UTH temperatures.

- Product Features

- FM: 33.9 GPa

- HDT: 266°C

- Chemical resistance

- Excellent wear/bearing performance

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Flame Rating

- Mechanical Properties

Value Units Test Method / Conditions Tensile Stress (Break, Type I, 5 mm/min) ¹¹ 165 MPa ASTM D638 Tensile Stress (Break) ¹¹ 253 MPa ASTM D638 Tensile Strain (Break, Type I, 5 mm/min) ¹¹ 0.9 % ASTM D638 Tensile Strain (Break) ¹¹ 1.6 % ASTM D638 Tensile Modulus (at 5 mm/min) ¹¹ 26120 MPa ASTM D638 Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ 253 MPa ASTM D790 Flexural Stress ¹¹ 253 MPa ASTM D790 Flexural Stress ¹¹ 254 MPa ISO 178 Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ 21400 MPa ASTM D790 Flexural Modulus ¹¹ 21400 MPa ASTM D790 Tensile Stress (Break, 5 mm/min) ¹¹ 166 MPa ISO 527 Tensile Stress (Yield, 5 mm/min) ¹¹ 166 MPa ISO 527 Tensile Strain (Break, 5 mm/min) ¹¹ 0.9 % ISO 527 Tensile Modulus (at 1 mm/min) ¹¹ 24890 MPa ISO 527 Flexural Modulus (at 2 mm/min) ¹¹ 22240 MPa ISO 178 Flexural Stress (Yield, at 2 mm/min) ¹¹ 254 MPa ISO 178 Flexural Stress (Break, 2 mm/min) ¹¹ 254 MPa ISO 178 Flexural Strain (Break, at 2 mm/min) ¹¹ 1.4 % ISO 178 - Physical Properties

Value Units Test Method / Conditions Density ¹¹ 1.51 g/cm³ ASTM D792 Density ¹¹ 1.54 g/cm³ ISO 1183 Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ 0.2 % ASTM D955 Mold Shrinkage (flow, 24 hrs) ᵍ ¹¹ 0.2 - 0.3 % ASTM D955 Mold Shrinkage (xflow, 24 hrs) ᵍ ¹¹ 0.4 - 0.6 % ASTM D955 Wear Factor Washer ¹¹ 24 10^-10 in^5-min/ft-lb-hr ASTM D3702 Modified: Manual Dynamic COF ¹¹ 0.47 - ASTM D3702 Modified: Manual Moisture Absorption (at 23°C, 50% RH, 24hrs) ¹¹ 0.02 % ASTM D570 Static COF ¹¹ 0.33 - ASTM D3702 Modified: Manual Moisture Absorption (at 23°C, 50% RH) ¹¹ 0.02 % ISO 62 - Thermal Properties

Value Units Test Method / Conditions Heat Deflection Temperature (at 0.45 MPa, 3.2 mm, Unannealed) ¹¹ 279 °C ASTM D648 Heat Deflection Temperature (at 1.82 MPa, 3.2mm, Unannealed) ¹¹ 260 °C ASTM D648 Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 278 °C ISO 75/Bf Relative Temperature Index (Electrical) ᵖ ¹¹ 130 °C UL 746B Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ 266 °C ISO 75/Af Relative Temperature Index (Mechanical with impact) ᵖ ¹¹ 130 °C UL 746B Relative Temperature Index (Mechanical without impact) ᵖ ¹¹ 130 °C UL 746B - Electrical Properties

Value Units Test Method / Conditions Surface Resistivity ¹¹ 100 Ω ASTM D257 - Impact Properties

Value Units Test Method / Conditions Izod Impact (Unnotched, at 23°C) ¹¹ 485 J/m ASTM D4812 Izod Impact (Notched, at 23°C) ¹¹ 53 J/m ASTM D256 Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ 26 kJ/m² ISO 180/1U Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ 4 kJ/m² ISO 180/1A - Injection Molding

Value Units Test Method / Conditions Drying Temperature ⁷ 120 - 150 °C - Drying Time ⁷ 4 Hrs - Melt Temperature ⁷ 315 - 320 °C - Front - Zone 3 Temperature ⁷ 330 - 345 °C - Middle - Zone 2 Temperature ⁷ 320 - 330 °C - Rear - Zone 1 Temperature ⁷ 305 - 315 °C - Mold Temperature ⁷ 140 - 165 °C - Back Pressure ⁷ 0.2 - 0.3 MPa - Screw Speed ⁷ 30 - 60 rpm - - Flame Characteristics

Value Units Test Method / Conditions UL Recognized (94V-0 Flame Class Rating) ᵖ 0.94 mm UL 94 - Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ᵖ UL ratings shown on the technical datasheet might not cover the full range of thicknesses and colors. For details, please see the UL Yellow Card.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- LNP™ Compounds Wear and Friction Solutions High Temperature Materials

While auto under-the-hood and industrial machinery might be the first to come to mind, high temperature application are not always driven by hot operating environment. Some application that may never see elevated use temperatures have to survive a hot manufacturing environment (lead-free solder, paint ovens). High temperature generally feature good chemical resistance as well.

The addition of an internal lubricant to a thermoplastic material can improve the wear resistance and can reduce the coefficient of friction in plastic parts. Traditional lubricants like PTFE and PTFE/Si blends are common. Compounds made with high temperature resins can provide wear performance comparable with externally lubricated metal parts.

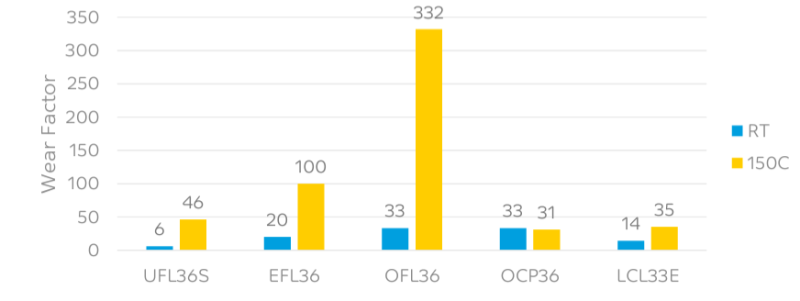

Wear at Elevated Temperatures

- LNP™ Compounds Wear and Friction Solutions Bearings, Bushings, Cams and Sliders

At the push of a button, windows move, doors lock, copies get made, and HVAC comes to life. These electromotive actions require gears, bearings, bushings and other wear surfaces to provide smooth, reliable, actuation forces. LUBRICOMP™ and LUBRILOY™ compounds can help deliver the high quality performance required.

Thermoplastic Bearings

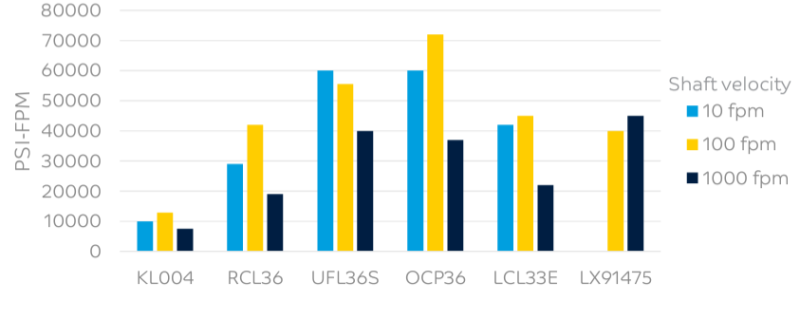

While resistance to wear is important for thermoplastic bushings/bearings, low friction can be more important. Heat generated from friction is often the limiting factor in plastic bearing applications. The operating load (P) and speed (V) of the application can be compared to the allowable, or “Limiting PV” of a candidate material. The data shown below was generated using a cylindrical half bearing test configuration, but modern thrust washer testers can be used to develop PV maps as well.

Internally Lubricated Compounds

The addition of an internal lubricant to a thermoplastic material can improve the wear resistance and reduce the coefficient of friction in plastic parts. Traditional lubricants like MoS2 , PTFE and PTFE/Si blends are common, with reinforcements like glass and carbon fiber adding strength and modulus. High temperature resins are sometimes required to resist deformation from friction generated heat.

Limiting Pressure Velocity

Packaging & Availability

- Regional Availability