In the Healthcare Industry over the last decades there has been a continued search for material solutions , that are addressing the macro trends in this industry of more regulatory oversight, cleaner and safer devices, non threatening, reduced patient anxiety operations, efficient, more personalized medical devices, that are portable, small and lightweight and last but not least, also more environmentally sustainable solutions

Plastics in Medical Devices

When operating with standard (non electrically conductive) plastics in medical devices there are 2 main challenges to be addressed . 1) In drug delivery applications, the issue of inconsistent dosing and dust , particle attraction & contamination can occur due to electrostatic effects and 2) Malfunctioning of critical supporting electronic devices, due to electromagnetic interference.

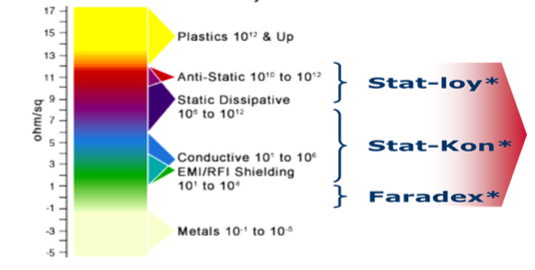

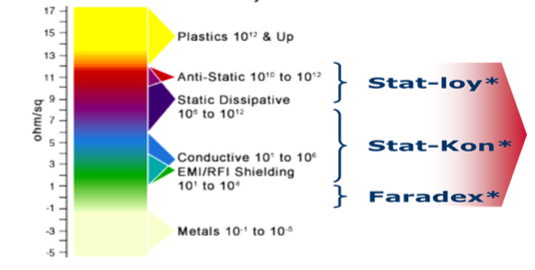

Electrically Conductive Compounds

The addition of a conductive filler to a thermoplastic material can increase the electrical conductivity and/or the EMI shielding capability of a thermoplastic, herewith reducing the aforementioned risks. Traditional fillers like carbon powder , fibers , anti-stat agents and stainless steel fibers are effective, and more novel and advanced technologies can provide additional features.. The resulting conductive compounds do exhibit a better carbon footprint versus plastics with a conductive paint and metals.