Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Highlights

Low slump concrete dosed with Superflo 443 becomes high slump concrete at the job site assuring good consolidation of concrete around reinforcing steel with little or no vibration.

- Advantages

- Cohesive and non-segregating

- Consistent and controlled time of set throughout entire dosage range

- Accelerated construction methods resulting in earlier completion dates

- Reduced contractor placement costs

- Higher and earlier ultimate strengths

- Better flowing concrete with minimal bleed water

- Improved durability with lower permeability

- Higher modulus of elasticity

- Increased resistance to freeze thaw cycleslower water to cement ratio for a given slump

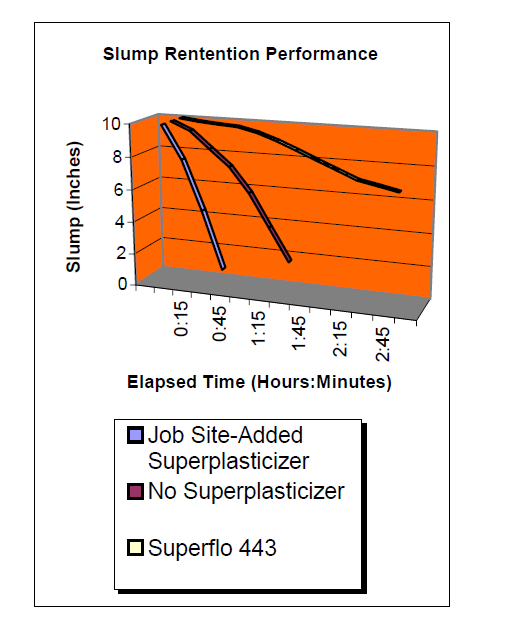

- Maximum slump retention for a superplasticizer

- Reduced shrinkage and creep

- Improved resistance to sulfate attack

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Uses

Superflo 443 is recommended for use in concrete where higher flowability and increased early and ultimate strengths are required.

Superflo 443 allows the contractor or superintendent to place concrete with improved and increased strength while lowering placement labor costs.

- Compatibility

Superflo 443 is compatible with all types of Portland cement, class C and F fly ash, silica fume, calcium chloride, fibers and approved air entraining, accelerating, retarding, and water reducing admixtures. Superflo 443 can be used in white, colored, and architectural concrete. For best results, each admixture must be dispensed separately into the concrete mix.

- Dosage Rate

SUPERFLO 443 is recommended for use at a dosage rate of 10 to 26 ounces per 100 pounds (652 mL to 1695 mL per 100 kg) of cementitious material.

Because local job conditions vary, contact your local RussTech technical service representative for further assistance if using outside recommended dosage ranges.

Properties

- Typical Properties

Value Units Test Method / Conditions Air Content 5.0 % - Ambient Temperature 65.0 °F - Concrete Temperature 68.0 °F - Slump After Superflo 443 7.0 Inches - Slump After Water 7.5 Inches - Slump Plain 1.0 Inches -

Regulatory & Compliance

- Specifications

Superflo 443 Conforms to:

ASTM C 494 Types A and F

ASTM C 1017 Type I

AASHTO M 194 Types A and F

CRD C 87 Types A and F

All other Federal and State specifications

Technical Details & Test Data

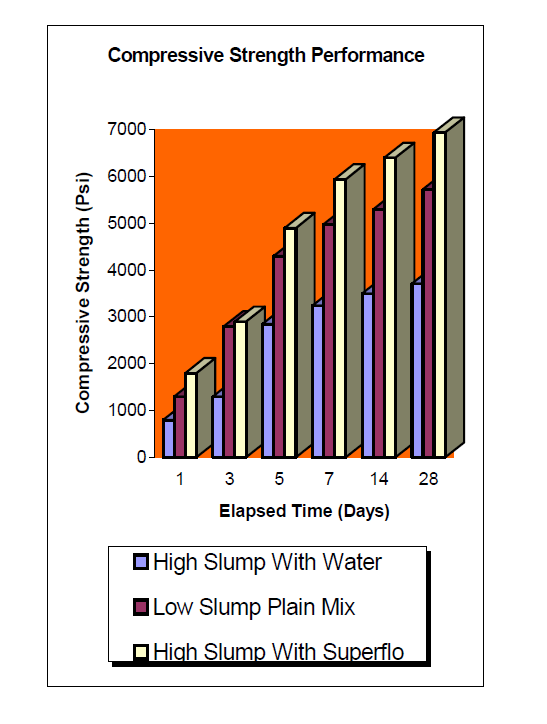

- Compresive Strength

Superflo 443 at 16 ounces per 100 pounds (1043 mL per 100 kg) cement

Mix 7 Day 28 Day Psi Mpa Psi Mpa Plain 4980 34.3 5730 39.5 High slump with water 3240 22.3 3710 25.6 Superflo 443 5940 41 6940 47.9

- Slump Retention

- Technical Note

Superflo 443 does not contain calcium chloride or any chloride-based components.

Superflo 443 will not initiate or promote the corrosion of steel in concrete used with:

- Galvanized steel flooring or roofing systems left for permanent construction

- Rebar, wire mesh or metal fibers

- Pre-cast, site cast, and prestressed steel reinforcement

- Steel cable in both pre-tensioned and post-tensioned applications

Packaging & Availability

- Packaging Type

- Packaging

5 gallon pails, 55-gallon drums, 275-gallon tote tanks and bulk delivery.

Storage & Handling

- Shelf Life

- 18 Months

- Storage

SUPERFLO 443 may freeze at temperatures below 32F (0C) If frozen, thaw at 40F (4C) or higher and reconstitute with mild agitation. Do not use pressurized air for agitation.