Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

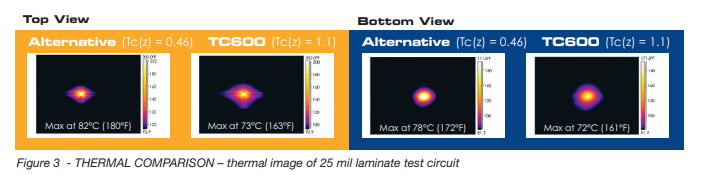

The increased thermal conductivity of TC600 provides higher power handling, reduces hot-spots and improves device reliability. This higher heat transfer within the substrate complements designs using coins, heat sinks or thermal vias to provide designers additional design margin in managing heat. In designs with limited thermal management options, TC600 significantly improves heat transfer where the primary thermal path is through the laminate. This results in reduced in junction temperatures and extends the life of active components, which is critical for improving power amplifier reliability, extending MTBF and reducing warranty costs. In addition, lower operating temperatures and chip-matching thermal expansion characteristics provide better reliability for component attachment prone to solder fatigue, solder softening and joint failure. TC600 has “Best-In-Class” Dielectric Constant Stability across a wide temperature range. This helps Power Amplifier and Antenna designers maximize gain and minimize dead bandwidth lost to dielectric constant drift as operating temperature changes. Dielectric constant stability is also critical to phase sensitive devices such as network transformers utilized for impedance matching networks utilized in power amplifier circuitry. TC600 has low Z-Direction CTE.This feature provides unsurpassed plated through hole reliability. TC600 is a “soft substrate” and irrelatively insensitive to stress from vibration. Its robust nature overcomes the brittleness of thermoset ceramic loaded hydrocarbons or ceramics (such as alumina or LTCC) through suspension of micro-dispersed ceramics in a relatively soft, woven fiberglass reinforced PTFE-based substrate. This gives RF designers the advantage of low loss, without sacrificing mechanical robustness required to fulfill the needs of shock, drop and impact testing requirements of electronics. It is preferred by board manufacturers, as it can be easily cut, drilled and routed without being sensitive to cracking.

- Features

- Best in Class” Thermal Conductivity (1.1 W/mK) and Dielectric Constant Stability across Wide Temperatures (-75 ppm/ºC)

- Very Low Loss Tangent provides Higher Amplifier or Antenna Efficiency

- Mechanically Robust; replaces brittle laminates that cannot withstand processing, impact or High G forces

- Priced Affordably for Commercial Applications

- High Peel Strength for Reliable Narrow Lines

- Benefits

- Heat Dissipation and Management

- Replace Ceramic in Some Applications

- Improved Processing and Reliability

- Large Panel Sizes for Multiple Circuit

- Layout for lowered Processing Costs

Applications & Uses

- Markets

- Applications

- Recommended Applications

• Power Amplifiers, Filters and Couplers

• Microwave Combiner and Power Divider Boards in Avionics Applications

• Small Footprint Antennas

• Digital Audio Broadcasting (DAB) Antennas (Satellite Radio)

• GPS & Hand-held RFID Reader Antennas

Properties

- Typical Properties

Value Units Test Method / Conditions Dielectric Constant at 1.8 MHz 6.15 - RESONANT CAVITY Surface Resistivity (E24/125) 9 x 10^8 MΩ IPC TM-650 2.5.17.1 Dielectric Constant at 10 GHz 6.15 - IPC TM-650 2.5.5.5 Surface Resistivity (C96/35/90) 3.1 x 10^9 MΩ IPC TM-650 2.5.17.1 Dissipation Factor at 1.8 GHz 0.0017 - RESONANT CAVITY Volume Resistivity (E24/125) 2.4 x 10^8 MΩ-cm IPC TM-650 2.5.17.1 Dissipation Factor tan d, at 10 GHz 0.002 - IPC TM-650 2.5.5.5 Volume Resistivity (C96/35/90) 1.6 x 10^9 MΩ-cm IPC TM-650 2.5.17.1 Temperature Coefficient of Dielectric - TC r at 10 GHz -75 ppm/°C IPC TM-650 2.5.5.5 Electrical Strength 34 kV/mm IPC TM-650 2.5.6.2 Dielectric Breakdown 62 kV IPC TM-650 2.5.6 Arc Resistance min. 240 seconds IPC TM-650 2.5.1 Td, Initial 512 °C IPC TM-650 2.4.24.6 Td, 5% 572 °C IPC TM-650 2.4.24.6 T260 min. 60 min IPC TM-650 2.4.24.1 Time to Delamination (T288) min. 60 min IPC TM-650 2.4.24.1 T300 min. 60 min IPC TM-650 2.4.24.1 Thermal Expansion, CTE (x,y) 50-150ºC 9, 9 ppm/°C IPC TM-650 2.4.41 Thermal Expansion, CTE (z) 50-150ºC 35 ppm/°C IPC TM-650 2.4.24 Expansion (50-260ºC), Zaxis 1.5 % IPC TM-650 2.4.24 Peel Strength to Copper after thermal stress 1.8 N/mm IPC TM-650 2.4.8 Peel Strength to Copper at elevated temperatures 1.8 N/mm IPC TM-650 2.4.8.2 Peel Strength to Copper after process solutions 1.6 N/mm IPC TM-650 2.4.8 Young’s Modulus 1930 kpsi IPC TM-650 2.4.18.3 Flexural Strength (M/C) 9.60/9.30 kpsi IPC TM-650 2.4.4 Tensile Strength (M/C) 5/4.30 kpsi IPC TM-650 2.4.18.3 Water Absorption 0.02 % IPC TM-650 2.6.2.1 Density 2.9 g/cm3 ASTM D792 Method A Thermal Conductivity - z 1.1 W/m/°K ASTM E1461 Thermal Conductivity - (x, y) 1.4 W/m/°K ASTM E1461 Specific Heat 0.94 J/g/°K ASTM E1461 Outgassing Total Mass Loss 0.02 % NASA SP-R-0022A Outgassing Collected Volatile Condensable Material 0 % NASA SP-R-0022A Outgassing Water Vapor Recovered 0 % NASA SP-R-0022A

Technical Details & Test Data

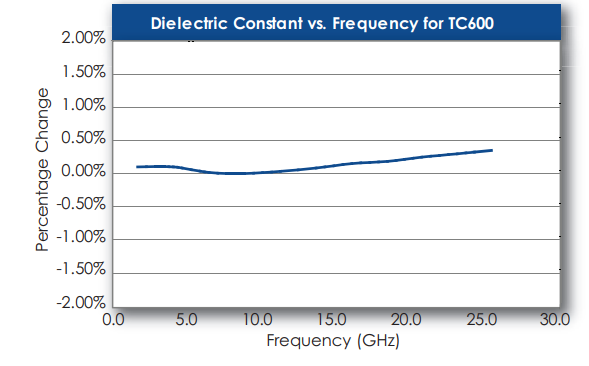

- Dielectric Constant vs. Frequency

Demonstrates the Stability of Dielectric Constant across Frequency.This information was correlated from data generated by using a free space and circular resonator cavity. This characteristic demonstrates the inherent robustness of Arlon Laminates across Frequency, thus simplifying the final design process when working across EM spectrum. The stability of the Dielectric Constant of TC600 over frequency ensures easy design transition and scalability of design

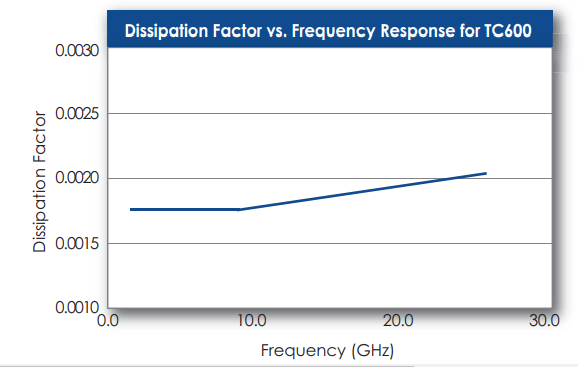

- Dissipation Factor vs. Frequency

Demonstrates the Stability of Dissipation Factor across Frequency.This characteristic demonstrates the inherent robustness of Arlon Laminates across Frequency, providing a stable platform for high frequency applications where signal integrity is critical to the overall performance of the application.

- Thermal Comparison

Packaging & Availability

- Material Availability

TC600 laminate is supplied with 1/2, 1 or 2 ounce electrodeposited or reverse treat copper on both sides. Other copper weights may be available. TC600 is available bonded to heavy metal ground planes. Aluminum, brass or copper plates also provide an integral heat sink and mechanical support to the substrate. When requesting samples of TC600 product, please specify thickness, cladding, panel size, and any other special considerations. Panel sizes cut from a master sheet include: 12” x 18”, 18” X 24”, 16” X 18”. Contact Customer Service for other custom panel sizes.