Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Extremely Low Loss Tangent

- Excellent Dimensional Stability

- Product Performance Uniformity

- Benefits

- Electrical Properties Are Highly Uniform Across Frequency

- Consistent Mechanical Performance

- Excellent Chemical Resistance

Applications & Uses

- Markets

- Applications

- Recommended Applications

- Military Radar Feed Networks

- Commercial Phased Array Networks

- Low Loss Base Station Antennas

- Missile Guidance Systems

- Digital Radio Antennas

- Filters, Couplers, LNAs

Properties

- Typical Properties

Value Units Test Method / Conditions Dielectric Constant at 10GHz 2.4 - 2.65 - IPC TM-650 2.5.5.5 Surface Resistivity 4.5 x 10^7 MΩ IPC TM-650 2.5.17.1 Dielectric Constant at 1MHz 2.4 - 2.65 - IPC TM-650 2.5.5.3 Volume Resistivity 1.2 x 10^9 MΩ-cm IPC TM-650 2.5.17.1 Dissipation Factor tan d, at 10 GHz 0.0018 - IPC TM-650 2.5.5.5 Dissipation Factor at 1 GHz 0.001 - IPC TM-650 2.5.5.3 Thermal Coefficient of εr -153 ppm/°C IPC TM-650 2.5.5.5 Adapted Peel Strength 14 lb/in IPC TM-650 2.4.8 Arc Resistance min. 180 seconds ASTM D-495 Tensile Modulus 706, 517 kpsi ASTM D-638 Tensile Strength 19, 15 kpsi ASTM D-882 Compressive Modulus 359 kpsi ASTM D-695 Flexural Modulus 537 kpsi ASTM D-790 Dielectric Breakdown min. 45 kV ASTM D-149 Density 2.31 g/cm3 ASTM D-792 Method A Water Absorption 0.03 % MIL-S-13949H 3.7.7 and IPC TM-650 2.6.2.2 Coefficient of Thermal Expansion - X Axis 14 ppm/°C IPC TM-650 2.4.24 Coefficient of Thermal Expansion - Y Axis 21 ppm/°C IPC TM-650 2.4.24 Coefficient of Thermal Expansion Z Axis 173 ppm/°C IPC TM-650 2.4.24 Thermal Conductivity 0.254 - ASTM E-1225 Outgassing Total Mass Loss 0.02 % NASA SP-R-0022A Outgassing Collected Volatile Condensable Material 0 % NASA SP-R-0022A Outgassing Water Vapor Regain 0.01 % NASA SP-R-0022A

Technical Details & Test Data

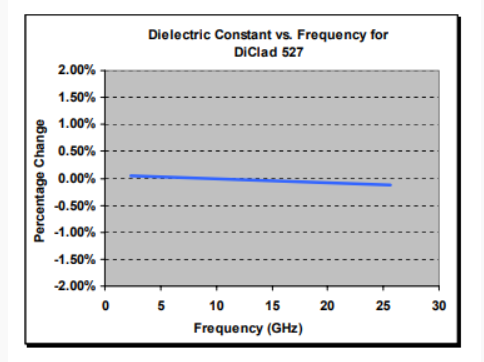

- Dielectric Constant vs. Frequency

Demonstrates the Stability of Dielectric Constant across Frequency. This information was correlated from data generated by using a free space and circular resonator cavity. This characteristic demonstrates the inherent robustness of the laminates across Frequency, thus simplifying the final design process when working across EM spectrum. The stability of the Dielectric Constant of DiClad over frequency ensures easy design transition and scalability of design.

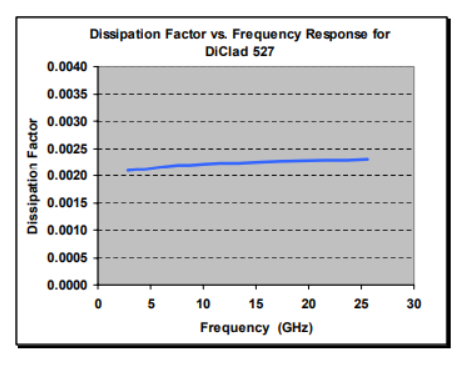

- Dissipation Factor vs. Frequency

Demonstrates the Stability of Dissipation factors across Frequency. This characteristic demonstrates the inherent robustness of the Laminates across Frequency, providing a stable platform for high-frequency applications where signal integrity is critical to the overall performance of the application.

Packaging & Availability

- Material Availability

DiClad laminates are supplied with 1/2, 1 or 2 ounce electrodeposited copper on both sides. Other copper weights and rolled copper foil are available. DiClad is available bonded to a heavy metal ground plane. Aluminum, brass or copper plates also provide an integral heat sink and mechanical support to the substrate. When ordering DiClad products please specify dielectric constant, thickness, cladding, panel size and any other special considerations. Available master sheet sizes include 36" x 48" and 48" x 54".