Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Highlights

Softening

CGS is a standard crosslinked cation resin optimized for residential and commercial applications. This type of resin is easier to regenerate than the higher crosslinked resins. CGS has marginal resistance to chlorine and other oxidants and is not ideal for high temperature and other high stress applications.

- Features

- Residential Softening

- Polystyrenic Gel

- Sodium Form

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Applications

Softening - Residential

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Polymer Matrix Styrenic Gel - - Ionic Form Sodium - - Fuctional Group Sulfonic Acid - - Particle Size 297 - 1190 μm - % max. 50 mesh (300µm) max. 1 % - Minimum Sphericity 90.0 % - Uniformity Coefficient 1.6 - - Temperature Limit 250.0 °F - Capacity (meq/mL) 1.9 - - Moisture Retention 40 - 52 % - Shipping Weight 49 - 51 lbs/ft³ - Regenerability Yes - - Reversible Swelling (Na to Ca) -5 to -3 % - - Recommended Operating Conditions

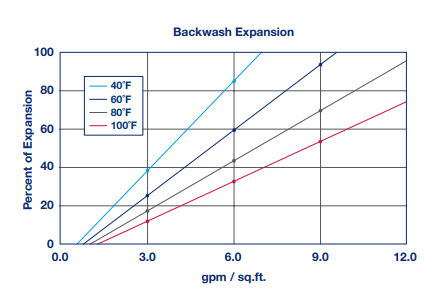

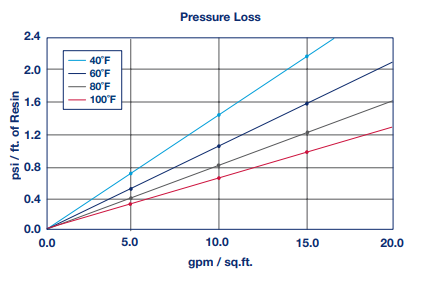

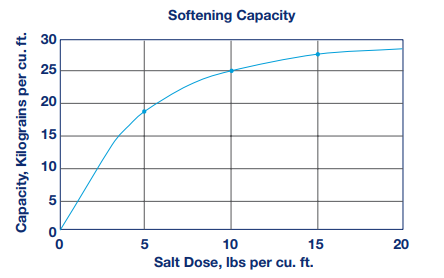

Value Units Test Method / Conditions Maximum Continuous Temperature Sodium Form 250.0 °F - Minimum Bed Depth 24.0 inches - Backwash Expansion 25 - 50 % - Maximum Pressure Loss 25.0 psi - Operating ph Range 0 - 14 - - Regenerant Concentration Salt Cycle 10 - 15 % NaCl - Regenerant Level 4 - 15 lbs./cu.ft. - Regenerant Flow Rate 0.5 - 1.5 gpm/cu.ft. - Regenerant Contact Time min. 20 minutes - Displacement Flow Rate Same as dilution water - - Displacement Volume 10 - 15 gallons/cu.ft. - Rinse Flow Rate Same as service flow - - Rinse Volume 35 - 60 gallons/cu.ft. - Service Flow Rate 1 - 10 gpm/cu.ft. -

Regulatory & Compliance

- Certifications

- WQA Gold Seal

- Kosher Certified

- Halal Certified

Technical Details & Test Data

- Product Technical Data

Capacity and leakage data are based on the following: 2:1 Ca:Mg ratio, 500 ppm TDS as CaCO₃, 0.2% hardness in the salt and 10% brine concentration applied co-currently through the resin over 30 minutes. No engineering downgrade has been applied.