Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Features

Flexibility of use

PureFlex polymeric plasticisers can be efficiently used as primary plasticizer, as well as secondary plasticisers in a mixture with ester plasticisers.

PureFlex does not change the shade of dyes

PureFlex plasticisers are colorless and clear, which makes them suitable for manufacturing colored plasticisers without affecting the hue of the dyes.

Environmentally-friendly

The manufacturing process of the PureFlex plasticisers does not involve the use of any harmful substances. We also offer polymeric plasticisers with increased contents of naturally sourced substrates.

A reliable partner

The efficiency of the PureFlex E1540 plasticiser in PVC foil manufacturing has been proved obtaining a certificate confirming the possibility of using the substance in products intended for contact with food.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Applications

The obtained processing parameters and properties of PureFlex plasticisers guarantee that they are the perfect choice for numerous applications in processing poly(vinylchloride), such as:

- Granulates

- Wire cladding

- Claddings

- Packaging foil

- Artificial leather

- Footwear

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Acid number max. 2,0 [mgKOH/g] - Viscosity at 25°C 7000 - 9000 [mPas] - Colour max. 150 Hazen - Density 1.10 - 1.15 g/cm³ -

Technical Details & Test Data

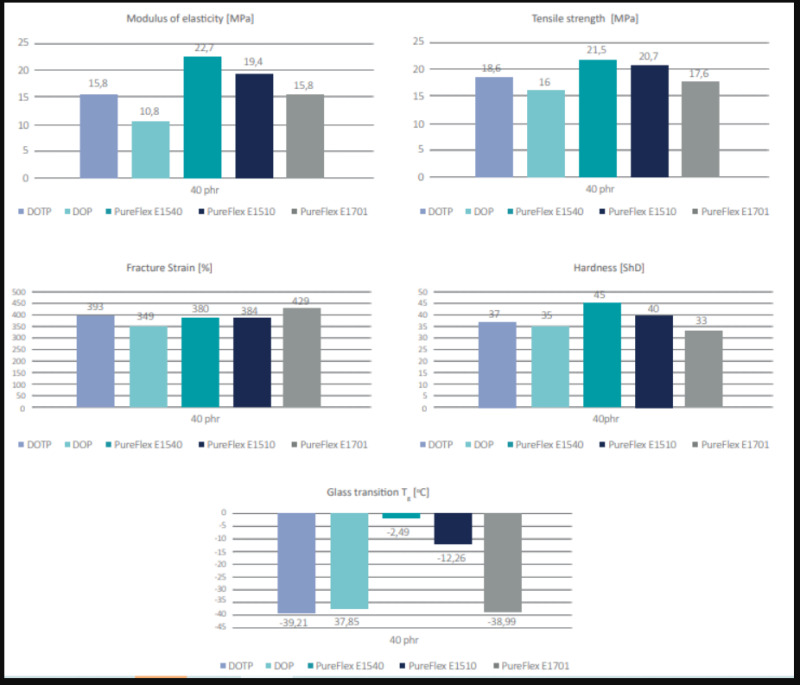

- Testing in PVC plasticiser with the use of 40 phr of plasticiser