Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 2082-79-3

- EC No.

- 218-216-0

- Technologies

- Product Families

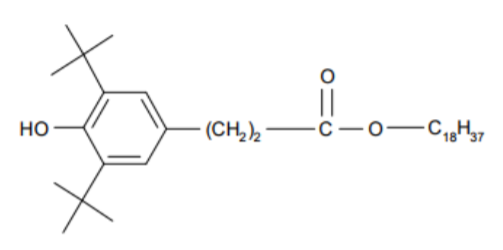

- Chemical name

Octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate

- CAS number

2082-79-3

- Chemical Structure

Features & Benefits

- Materials Features

- Features & Benefits

PUREstab 1076 can be used in combination with other additives such as co-stabilizers, e.g. thioethers (long term heat stabilizers), phosphites, phosphonites (secondary antioxidant), light stabilizers and other functional stabilizers. It is of particular interest to mention the enhanced effectiveness obtained by combining PUREstab 1076 with PUREfos 168.

Applications & Uses

- Compatible Polymers & Resins

- Applications

At concentrations of 0.05% - 0.2%, PUREstab 1076 is providing long-term thermal stability to the polymer. In polyolefins the recommended concentration levels range between 0.1% and 0.4% depending on the matrix, processing conditions and longterm thermal stability requirements. For styrene homo- and copolymers it is ranging from 0.1 to 0.3%, in hot melt adhesives, from 0.2% to 1.0%, in synthetic tackifier resins, from 0.1% to 0.5%.

- Guidelines for Use

At concentrations of 0.05% - 0.2%, PUREstab 1076 is providing long-term thermal stability to the polymer. Nevertheless, concentrations up to several percent may be suitable depending on the requirement of the end application and the substrate to be stabilized.

In polyolefins the recommended concentration levels of PUREstab 1076 range between 0.1% and 0.4% depending on the matrix, processing conditions and longterm thermal stability requirements. The optimum level has to be determined depending on the application requirement.

The concentration levels of PUREstab 1076 recommended:

- for styrene homo- and copolymers is ranging from 0.1 to 0.3%

- in hot melt adhesives it is ranging from 0.2% to 1.0%,

- in synthetic tackifier resins it is ranging from 0.1% and 0.5%.

Properties

- Color

- Physical Form

- Appearance

- White fine flowing powder

- Soluble in

- Water, Ethanol, Chloroform, Acetone, Methanol, Benzene, Ethyl Acetate, toluene, Cyclohexane, N-hexane

- Physical Properties

Value Units Test Method / Conditions Melting Range 50 - 55 °C - Flash Point min. 270 °C - Vapor Pressure (at 20°C) 2.5e-07 Pa - Bulk Density (Powder) 500 - 650 g/l - - Solubility

Value Units Test Method / Conditions Acetone (at 20°C) 19.0 g/100g - Chloroform (at 20°C) 57.0 g/100g - Ethyl Acetate (at 20°C) 38.0 g/100g - Methanol (at 20°C) 0.6 g/100g - Cyclohexane (at 20°C) 49.0 g/100g - Benzene (at 20°C) 57.0 g/100g - Ethanol (at 20°C) 1.5 g/100g - n-Hexane (at 20°C) 32.0 g/100g - Toluene (at 20°C) 50.0 g/100g - Water (at 20°C) max. 0.01 g/100g -

Technical Details & Test Data

- Molecular weight

531 g/mol

Safety & Health

- Handling & Safety

In accordance with good industrial practice, handle with care and avoid unnecessary - personal contact. Avoid continuous or repetitive breathing of dust. Use only with adequate ventilation. Avoid dust formation and ignition sources. For more detailed information please refer to the material safety data sheet.

Storage & Handling

- Storage

This product may be stored in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.