Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 71878-19-8

- EC No.

- 615-678-9

- Technologies

- Product Families

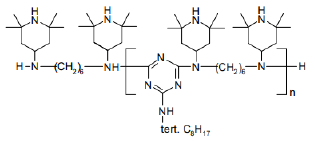

- Chemical Structure

Features & Benefits

- Materials Features

- Key Attributes

PUREsorb 944 imparts excellent light stability to thin articles, particularly fibers and films. In thick cross sections it is specifically suitable for polyethylene articles. In addition, its use is recommended for applications requiring indirect food contact approval. PUREsorb 944 is highly effective as a long-term thermal stabilizer in thin and thick articles and shows good extraction resistance.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

PUREsorb 944 areas of application include polyolefins (PP, PE), olefin copolymers such as EVA as well as blends of polypropylene with elastomers. In addition, in certain instances PUREsorb 944 is highly effective in polyacetals, polyamides, polyurethanes, flexible and rigid PVC, as well as PVC blends and in certain styrenic elastomer and adhesive specialty applications.

Films (LDPE & LLDPE) 0.10 - 1.0% Fibers (PP) 0.10 - 1.4% Tapes (HDPE & PP) 0.10 - 0.8% Thick section (HDPE, LDPE, LLDPE & PP) 0.05 - 1.4%

Properties

- Color

- Physical Form

- Appearance

- White to slightly yellowish white to slightly yellowish granules and powder

- Physical Properties

Value Units Test Method / Conditions Melting Range 100 - 135 °C - Vapor Pressure 1010000.0 Pa - Flash Point min. 150 °C - Specific Gravity (at 20°C) 1.01 g/cm3 - - Solubility

Value Units Test Method / Conditions Acetone (at 20°C) min. 50 g/100g - Ethyl Acetate (at 20°C) min. 50 g/100g - Methanol (at 20°C) 3.0 g/100g - Methylene Chloride (at 20°C) min. 50 g/100g - Chloroform (at 20°C) min. 50 g/100g - Toluene (at 20°C) min. 50 g/100g - n-Hexane (at 20°C) 40.0 g/100g - Water (at 20°C) max. 0.01 g/100g -

Storage & Handling

- Product Handling

In accordance with good industrial practice, handle with care and avoid unnecessary personal contact. Avoid continuous or repetitive breathing of dust. Use only with adequate ventilation. Avoid dust formation and ignition sources.