Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

- Excellent adhesive strength

- Excellent resistance to vibration

- Easy to use – no mixing required

- High shear and peel strength

- Good impact strength

- High temperature resistance

- Good resistance to chemicals

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Surface Preparation

Surfaces should be clean, dry and grease-free before applying the adhesive. Use a suitable solvent (such as acetone or isopropanol) for the degreasing of surfaces. Some metals such as aluminum, copper and its alloys will benefit from light abrasion with emery cloth (or similar), to remove the oxide layer.

- Directions for Use

- The adhesive should be dispensed from the cartridge via the nozzle supplied (this can be cut to give the appropriate sized bead to cover the bond area).

- Apply the adhesive to one surface and avoid entrapping air.

- Assemble parts applying sufficient pressure to ensure the adhesive spreads to cover the entire bond area.

- Use a jig / clamp to prevent parts moving during cure.

- It is advisable not to disturb the joint until the adhesive is fully cured.

- Cure with heat – see page one for cure schedule.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Physical Properties of Uncured Adhesive (Measured)

Chemical composition Epoxy Resin Appearance Silver-gray Viscosity at 25°C 1,000,000 to 2,000,000 mPa.s (cP)

(Helipath, 2rpm)Specific gravity 1.5 Flow at high temperature No flow Maximum gap fill 5 mm 0.2 in Cure speed (oven) * 130° C (266°F): 75 minutes

150°C (300°F): 60 minutes

170°C (338°F): 40 minutes- Physical Properties of Cured Adhesive (Measured)

Shear strength* (ISO4587) Steel 27 – 41 N/mm² (4000 – 6000 psi)

Aluminum 17-31 N/mm² (2500–4500 psi)

Zinc 14 - 27 N/mm² (2000 – 4000 psi)Shear strength steel to ferrite >14 N/mm² (>2000 psi) Substrate failure

Impact Strength (ASTM D-950) 25-35 KJ/m² Hardness (ISO868) 80-85 Shore D E-modulus 4.8 GPa Elongation at break

(DIN 53504)<3% Coefficient of thermal expansion 45 x 10-6 mm/mm/°C (below Tg)

160 x 10-6 mm/mm/°C (above Tg)Thermal conductivity 0.55 W/(m.K) Glass transition temperature

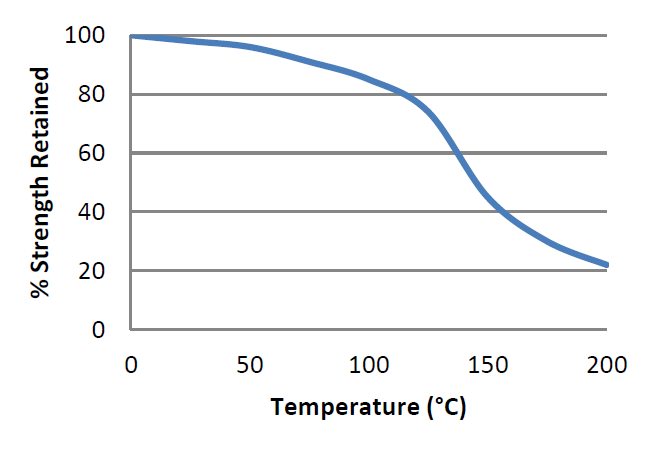

(Tg – DSC)120°C (250°F) Cure speed (induction) <3 minutes - Hot Strength

“Hot strength” shear strength tests performed on mild steel. Fully cured then conditioned to pull temperature for 30 minutes before testing. ES550 can withstand higher temperatures for brief periods (such as for paint baking and wave soldering processes) providing the joint is not unduly stressed.

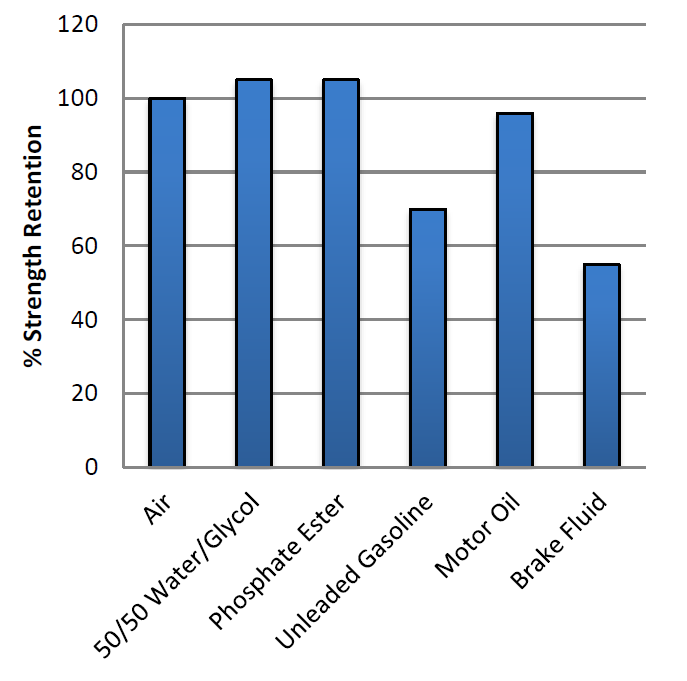

The minimum temperature the cured adhesive can be exposed to is -40°C (-40°F) depending on the materials being bonded.- Chemical Resistance

Specimens were immersed for 30 days at 85ºC and tested at room temperature.

Storage & Handling

- Storage Temperature

2 to 7°C (35 to 45°F)