Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

- Watertite JS is a specially designed formulation for use with concrete and steel expansion joints, up to maximum of 3 ½ (8.9 cm) in width. The adhesion to concrete and steel is chemical, ensuring a permanent bond. Rain, snow or water will not effect the sealant. Pot life and curing time may be adjusted to suit any particular job situation without changing or affecting the physical properties and performance of the cured sealant. Watertite JS offers many advantages.

- The sealant keeps water and moisture out indefinitely. Being a liquid when applied, it finds its own level and thereby fills small cracks and imperfections, giving a perfect seamless seal and bond to all surfaces. Because of its excellent adhesive properties, moisture will not be able to penetrate the seal.

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Uses

Watertite JS is used for treatment of joints and cracks in new or existing structures.

- Design Limitations

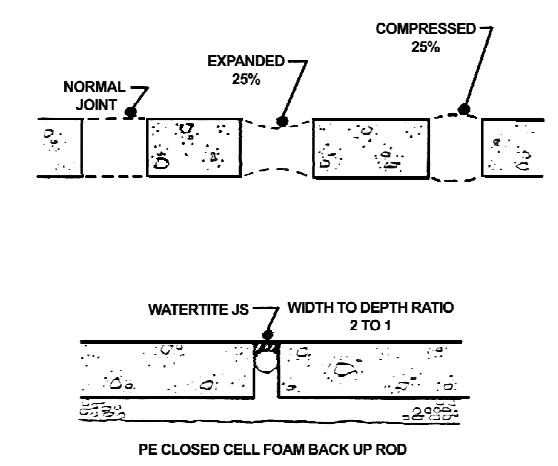

Watertite JS is not to be applied to surfaces that are either wet, oily, frosted, dirty or contaminated in any way. Watertite Surface Conditioner should be used on all surfaces. The depth of the sealant in the joint should never be greater than the width of the joint. Preferably, the depth should equal ½ of the width. NOTE: Consult PennKote Limited for specific data on applications not detailed in this literature.

- Applications

- The two pre-measured portions should be thoroughly mixed by means of a double bladed agitator attached to a low speed electric drill. Mix the material for a period of not less than eight minutes.

- Improper mixing will not allow material to cure properly. Watertite JS may be applied either by pouring or caulking gun at temperatures as low as –18oC (0o F). The quality of the sealant is not changed by freezing temperatures. In order to obtain the best mixing and application results, Watertite JS should be used or mixed at approximately 16oC (60o F), whenever possible.

- A power brush and compressed air should be used for cleaning joints or cracks. Use a gas torch to dry out any wet surfaces. For expansion joint backup install a closed cell PE foam, or other suitable supporting material.

Application Details

- Caution

Flammable. Do not heat container with open flame.

Properties

- Physical Properties

Value Units Test Method / Conditions Elongation (Cured For 72 Hours At 57°C) 450.0 % ASTM D-412 Hardness 95.0 Shore 00 ASTM D-2240 Brittle Point -61.0 °C ASTM D-746 - Typical Properties

Value Units Test Method / Conditions Cure Time (16°C To 27°C) approx. 6 hours - Pot Life (16°C To 27°C) approx. 40 minutes - Flow Characteristics Self-levelling or gun grade - - Toxicity Cured sealant is non toxic - - - Physical Properties

- Resiliency - Not altered at temperatures as high as 82oC (180o F) at 40oC (120o F) 94% - Recovery within 7.6m (25') at 65.5oC (145o F) 97% - Recovery within 7.6m (25').

- Bond Extensibility* (ASTM D-1191-65) - 5 cycles of extension at -17.8 C; 25% .......pass (minimum requirement); 35% .......pass; 50% .......pass.

- Environmental Resistance - Excellent resistance to moisture, ozone, ultra-violet, extreme temperatures and industrial atmospheres.

- Chemical Resistance - Excellent resistance to salts, diluted acids and alkali solutions, bacteria and fungi.

Technical Details & Test Data

- Coverage Chart

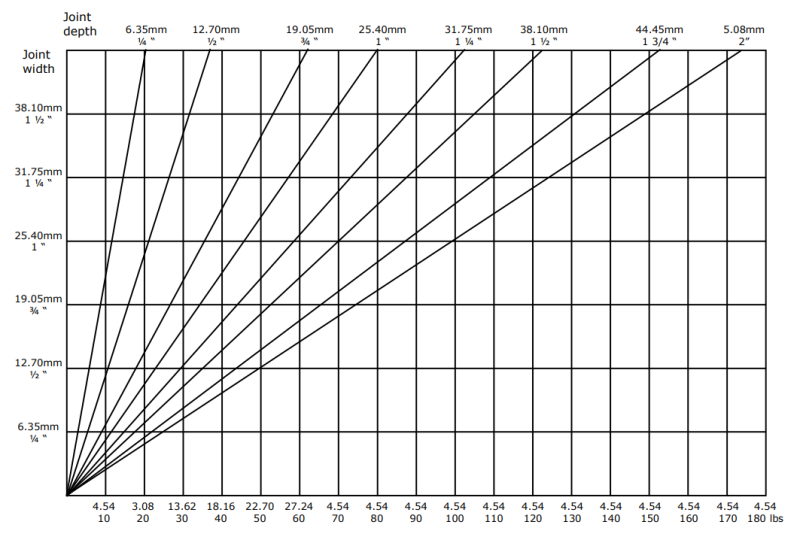

Chart 1 - pounds of watertite js for 30.5m (100ft.) long joint

Packaging & Availability

- Packaging

Watertite JS is packaged in a 22.7 liters (5 imperial gallon) pail with an activator.

Storage & Handling

- Shelf Life

- Part "A" and "B" unmixed indefinite