Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Features & Benefits

- Provides protection from lightning strikes

- Provides a high quality paintable surface

- Minimizes surface porosity

- Natural color

- Co-curable with most epoxy prepreg materials

- Improved surface finish on honeycomb core structures

- UV resistant

- Manufactured with E-780-1 resin

- Product Forms

- 0.030 psf standard weight surfacing film with woven fiberglass reinforcement

- 0.015 psf Cu mesh

- 0.022 psf Cu mesh

- 0.040 psf Cu mesh

- 0.016 psf Al mesh

- Other metal mesh weights available upon request

- 36” wide standard rolls

Applications & Uses

- Markets

- Applications

- Applications

- Primary and Secondary Aircraft Structure Surfaces

- Lightning Strike Protection

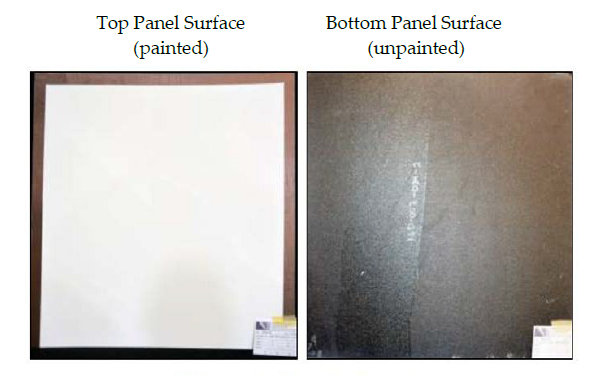

- Painted or Unpainted Composite Surfaces

- UV Protection (for unpainted or green structures)

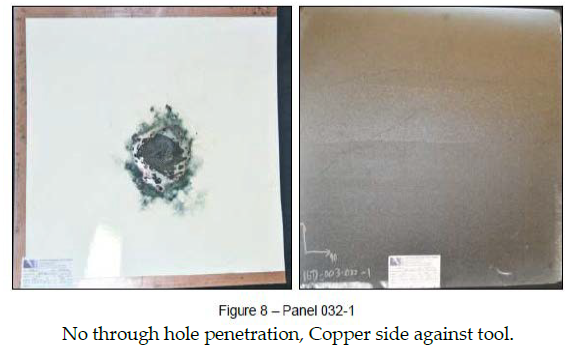

- Zone 1C High Voltage 330 µm min. painted test panel example

- Available in Natural or Black

- Autoclave/Oven Cure Cycle

- Cure cycle set up based on underlying epoxy prepreg material

- Electroglide® surfacing film can be cured using autoclave or vacuum/oven cure cycles

- Electroglide® surfacing film is co-cure compatible with both 250°F and 350°F epoxy cure cycles. For cure cycles below 250°F or above 365°F contact your local sales and technical service representative or customer service at Park Aerospace Corp. at +1.316.283.6500.

Properties

- Mechanical Properties

Value Units Test Method / Conditions Metal Mesh Type 0.015 Cu lb/ft2 - Reinforcement Areal Weight 47 gsm - Dry Resin Content 47 % - Cured Single Ply Thickness 0.0035 in - - Physical Properties

Value Units Test Method / Conditions Prepreg Areal Weight 0.045(220) lb/ft2 gsm - Resin Flow (260°F, 150 psi) 20 % - Gel time (250°F/121°C) 25 minutes - Gel time (350°F/177°C) 0.8 minutes - Volatiles (350°F/177°C, 60 min) max. 1.0 % -

Technical Details & Test Data

- Lightning Strike Representative Testing

Tested to Zone 1C Requirements

Storage & Handling

- Prepreg Storage Life

- Out Life: 30 days @ 75°F

- Shelf Life: 6 months @ 40°F 12 months @ 0°F