Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

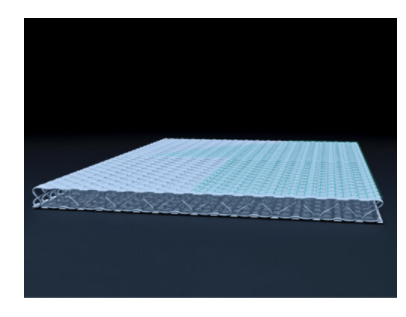

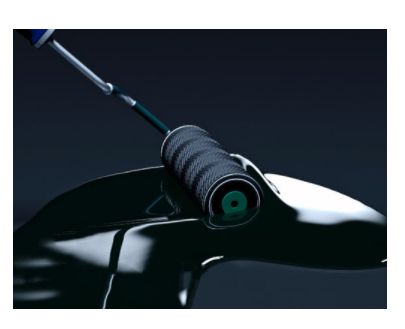

Once resin is applied to the ParaGlass fabric, the pillars’ capillary function creates a permanent hollow space. When applied, resin saturates the glass yarn without filling the empty space between the deck layers. Since only a minimal amount of resin is needed, resin waste through oversaturation is a thing of the past.

- Features

- Flexible

- Strong

- Fire-Resistant

- Lightweight

- Corrosion-resistant

Applications & Uses

- Markets

- Applications

- Composites End Use

- Composites Processing Methods

- Fiberglass Fabrics for Structural Applications

Parabeam 3D glass fabrics are woven out of E‑glass yarn for easy, quick production of high-quality sandwich constructions. Two bi-directionally woven deck layers are bonded together by vertically braided 8‑shaped pillars. The pillars act like springs and push the deck layers apart to a predefined height.

This strong and lightweight sandwich structure has may advantages over traditional sandwich fabrics, as well as wood and laminate products.

Properties

- Physical Form

Technical Details & Test Data

- Hand Lay-Up Process

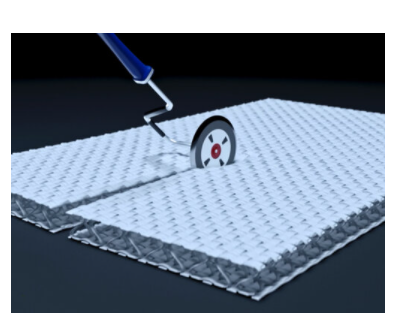

The four methods of creating the finished product are: hand lay-up, vacuum infusion, closed mold and inline product.

STEP 1 | MEASURE FABRIC

Measure the surface of the fabric and calculate fabric weight to determine the amount of resin needed.

STEP 2 | CUT FABRIC

Cut the fabric to the needed size with a tool such as a rotary cutter or scissors.

STEP 3 | APPLY RESIN

Apply 40% of the calculated resin to the mold and spread it evenly.

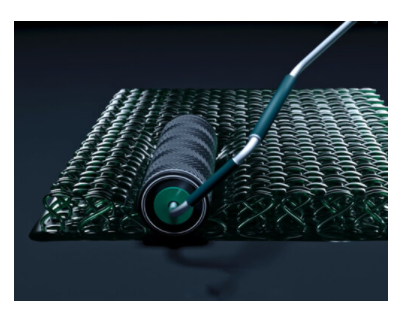

STEP 4 | ROLL FABRIC

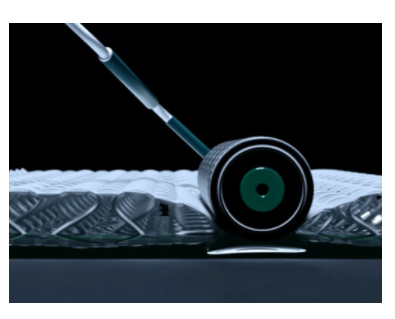

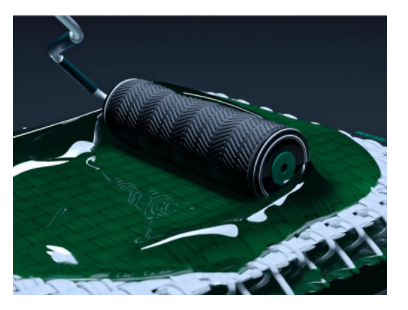

Roll the fabric to ensure that the resin is distributed evenly.

STEP 5 | APPLY REMAINING RESIN

Apply the remaining resin and spread it evenly. It will automatically start absorbing into the fabric.

STEP 6 | ROLL FABRIC

Lightly roll the fabric against the pile direction to ensure an optimal rise.