Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

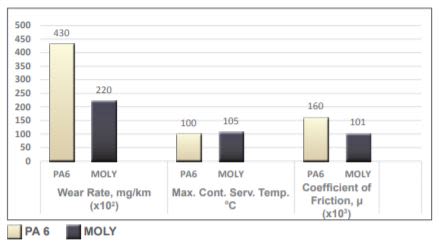

MoS2 provides a degree of self lubrication leading toan improvement in the wear properties of the material.These improved properties, combined with lowerwater absorption, extend the range of applications thatMoly has over Natural cast nylon. Dynamic bearing applications at elevated operating temperatures of up to105ºC are particularly suited to this material.

- Benefits

- Increased superficial hardness provides excellent machine ability

- Improvement in wear properties as a result of dry lubricant

- Improved anti-friction properties

- Improved mechanical properties

- Elevated operating temperatures

- Lower water absorption

- Improved dimensional stability

- Excellent chemical resistance properties

- Good PV and load bearing capabilities

- Extended range of applications

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Industry Users

- Aerospace

- Cranes

- Railways

- Conveyors

- Ship building

- Offshore

- Food and drink packaging

- Agriculture

- Steel mills

- Waste Management

- Quarrying and mining

- Construction

- Applications

- Sheaves

- Wear pads

- Rollers

- Bearings

- Spacers

- Bush

- Slide pads

- Chain Wheel

- Chain sheaves

- Hose Clamp

- Wear strips

- Wear plates

- Spacer

- Bespoke Components

Properties

- Color

- Physical Form

- Mechanical Properties

Value Units Test Method / Conditions Compressive Modulus 2500-2700 MPa ISO 604:2002 Compressive Strength 105 MPa ISO 604:2002 Density 1.15 g/cm3 ISO 1183:1997 Dynamic Coefficient of Friction 0.101 - - Elongation at Break min. 20 % ISO 527-1/2:1993 E-modulus 3800-4000 MPA ISO 527-1/2:1993 Flexural Modulus 3000-3200 MPa ISO 178:2001 Flexural Strength 100-110 MPa ISO 178:2001 Hardness (Shore D ) 80 Shore D ISO 868: 2003 Izod Impact Strength 5.5-7.0 kJ/mm2 ISO 180:2000 K-Factor (wear factor) 2.2x10E- mm3/Nm - Limiting PV 100 MPa/m - Tensile Strength at Yield 75-80 MPa - Water Absorption (24 hrs Saturation) 6.3 % - Water Absorption (24 hrs) 0.2 % - - Thermal Properties

Value Units Test Method / Conditions Coefficient of Linear Thermal Expansion 8.51e-05 °C-1 - Flammability HB - - Glass Transition Temperature 68 °C - Heat Deflection Temperature, HDT/A 80 °C - Maximum/Minimum Continuous Service Temperatures 105/-40 °C - Maximum/Minimum Intermittent Service Temperatures 170/-100 °C - Melting Temperature 221 °C - Thermal Conductivity 0.28 W/moC - - Electrical Properties

Value Units Test Method / Conditions Comparative Tracking Index 600 CTI IEC 60093:1980-01 Dielectric Constant 3.7 - 4 - IEC 60250:1969-01 Dielectric Strength 25 kV/m IEC 60243:-1:1998-01 Dissipation Factor 0.11 - IEC 60250:1969-01 Moisture Absorption (Equilibrium) 2.1 % ISO 62:1999 (modified) Surface Resistivity 1x10E12 ohm.m IEC 60093:1980-01 Volume Resistivity 1x10E13 ohm.m IEC 60243:-1:1998-01

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Moly

Packaging & Availability

- Availability

Nylacast Moly is available as standard plate, rod and thousands of tubes OD/ID configurations in several different lengths.