Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- CAS No.

- 51981-21-6

- EC No.

- 257-573-7

- Technologies

- Product Families

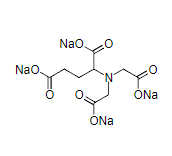

- Chemical Name

- Glutamic acid, N,N-diacetic acid, tetra sodium salt

- Molecular Formula

- Chemical Formula

- GLDA-Na₄

- Molecular Weight

- 351.1

Features & Benefits

- Benefit Claims

- Labeling Claims

- HII Features

- Product Highlights

- Readily biodegradeable under aerobic and anaerobic conditions

- Ultimately biodegradeable: being converted completely to CO2 and H2O

- Safe for humans and the environment

- Manufactured from L-Glutamic Acid, a naturally occuring amino acid

- NTA Free and does not have a Prop 65 warning

- Key Benefits

An important ingredient in Personal Care formulations providing benefits that include:

- Enhancing the effectiveness of biological preservatives

- Use less preservatives

- Effective on molds and both gram positive and gram negative bacteria

- Hard water management

- Improved foam

- Better cleansing

- Improved shelf life and product appearance

- Preventing rancidity

- Protecting the intended color and odor of your formulation

- Enhancing the effectiveness of biological preservatives

Applications & Uses

- Markets

- Applications

- Application Format

- Bath & Shower Applications

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Recommended Applications

- Boosting agent for disinfecting products (with low skin irritation) Improved detergency at high water hardness Hard surface cleaning performance is improved in combination with gluco(hepto)nates Scale removal at high pH Scale inhibitor in laundering and dishwashing applications.

- Booster for stain removal in dish washing detergents better than citrates and phosphates Scum inhibitor in bathroom cleaners Improved cleaning & foaming in shampoo applications.

- Storage stabilization of bleaching agents (perborates / percarbonates) and unsaturated alkyl chain based surfactants. Transport cleaners: Oil and Iron removal at high pH replacement for NTA

Properties

- Physical Form

- Appearance

- Clear liquid, Clear Liquid

- Odor

- Slightly ammonia like

- Miscible in

- Water

- Miscible In

- Water, Water at low pH**, Ethylene Glycol**, 5M NaOH**

- Typical Properties

Value Units Test Method / Conditions Assay min. 47.4 Wt% Freezing Point max. -15 °C COD 345 - 385 mg/g - Characteristics

Value Units Test Method / Conditions Crystallization Point max. -15 °C - Electro Conductivity 4.75 mS/cm - NTA-Nas Content max. 0.10 % - - Specifications

Value Units Test Method / Conditions Assay (as GLDA-Na) min. 47.4 % - Color max. 250 - APHA Density approx. 1400 kg/m³ - NTA-Nas Content max. 0.10 % - pH (1% w/v dilution) 11.0 - 11.8 SMA 176.18 - Theoretical Properties

Value Units Test Method / Conditions Calcium Content (at pH 6 - 14) 55.0 mg metal/g - Copper Content (at pH 2 - 12) 85.0 mg metal/g - Ferric Content (at pH 2 - 8) 75.0 mg metal/g - Magnesium Content (at pH 5 - 10) 35.0 mg metal/g - Manganese Content (at pH 5 - 10) 75.0 mg metal/g - Zinc Content (at pH 3 - 12) 90.0 mg metal/g - - Note

Dissolvine® GL-47-S is a high purity, versatile and readily biodegradable chelate based on L-glutamic acid, a natural and renewable raw material.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Endorsements

- The U.S. Department of Agriculture Bioprefered Procurement Program has certified that Dissolvine GL is 58% biobased

- Listed on the United States Environmental Protection Agency “Safer Choice”, it is also approved for direct release to the environment

- Compliant to European Directive on Cosmetic Products EC 1223/2009 including Article 18 (Chapter V) on animal testing

- Whole Food Market, acceptable to Premium Body Care Standard

Technical Details & Test Data

- Technical Details

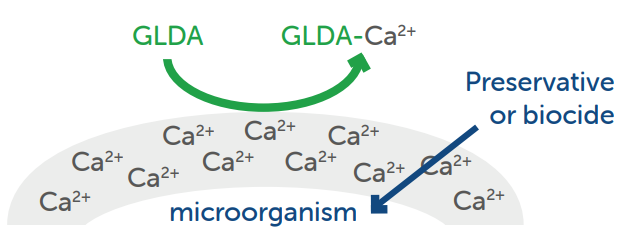

Maximize the performance of your biocide and preservatives

Dissolvine GL-47-S is an important ingredient in formulations providing benefits that enhance the effectiveness of biocides and biological preservatives. Dissolvine GL-47-S is effective on molds and both Gram Positive and Gram Negative bacteria. When you include Dissolvine GL-47-S in the formulations, you can significantly reduce the amount of active needed while preserving efficacy and save on formulation costs.

Species is deprived of multivalent cations weakening the outer surface and more vunerable for the action of preservatives.

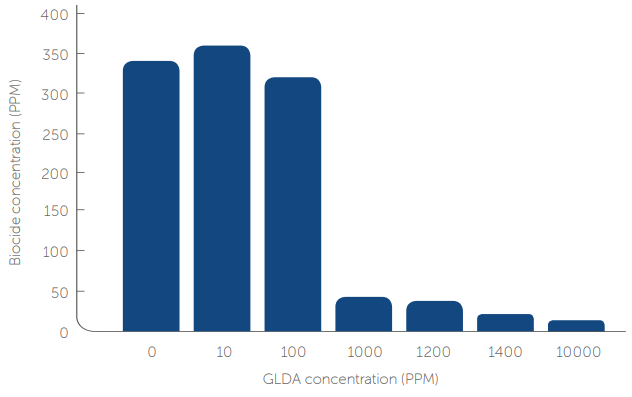

Amount of Arquad® MCB-50 needed to obtain 99.9% kill (Pseudomonas aeruginosa).

- Chemical and Physical Properties

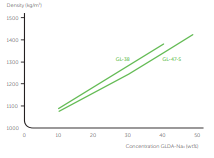

Dissolvine® GL product range including various chemical and physical properties. Dissolvine® GL-38 (offered in EMEA) and Dissolvine® GL-47-S (offered worldwide) are standard multi-purpose liquid chelating agents. The primary difference in these products is the active ingredient content (38 % vrs 47%) and also that the ‘S’ version is high purity (NTA free). Dissolvine® GL-PD-S is a spray dried equivalent of the liquid product, Dissolvine® GL-47-S, is convenient for the preparation of highly concentrated formulations (solid or liquid). This solid product readily dissolves in water to yield a clear, slightly yellow liquid, is hygroscopic and should be stored in closed bags or containers until it is used.

Liquid Density

The density of the liquid can be used as a quick reference to check the concentration of the material. See figure 1.

Figure 1: Density of Dissolvine® GL plotted against GLDA-Na4 concentration based on GL-38 or high purity GL-47-S.

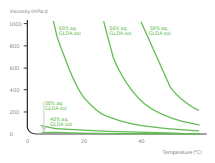

Viscocity

Viscosity is an important parameter for handling products and is dependent on concentration and temperature. Figure 2 shows the viscosity of various concentrations of GLDA-Na4 solutions as a function of temperature.

Figure 2: Graph of the viscosity of various concentrations of Dissolvine® GL at different temperatures, using GL-PD-S as starting material.

Storage & Handling

- Storage Conditions

- Store in original packing or in PVC, PP, PE, stainless steel or bituminized tanks.

- Avoid contact with aluminum, zinc, nickel, copper and copper alloys. It is advised to re-test the material after three years of storage.