Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- CASE Ingredients Features

- HII Features

- Key Benefits

- Efficient and versatile compatibilizer, useful to create stable colloidal systems, to avoid agglomeration of pigments and/ or coagulation of the binder

- Effective in providing for good color acceptance when adding a colorant to the white base

- Capable of increasing the gloss of the paint

- Can improve the freeze-thaw stability

- Non toxic and readily biodegradable according to regulation (EC) No. 1272/2008

- Very low content of VOC

- A non label and non irritant product according to the European directive 1999/45/EC and EC 1272/2008

- Compatible with all other surfactant types, i.e. nonionic, anionic and cationic

- Stable under alkaline and acidic conditions

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating Type

- Home Care Applications

- I&I Cleaning Applications

- Suggested Use Level

- 0.2% Based on total weight of the paint

- Applications

- When used in a white base paint, the starting recommendation for dosage is 0.2% based on the total weight of the paint.

- Recommendation is to add the Berol 185 in the grind, as to facilitate an improved wetting and distribution of the various surface active ingredients on the pigments.

- For enhanced color acceptance, Berol 185 works especially well in formulations based on anionic stabilized systems.

Properties

- Physical Form

- Appearance

- Clear liquid

- Soluble in

- Water, Ethanol, Propylene glycol, 2-propanol

- Dispersible in

- Low aromatic solvent, White spirit, Xylene

- Physical Properties

Value Units Test Method / Conditions Density (at 20°C) 1000 kg/m³ - - Typical Properties

Value Units Test Method / Conditions Color max. 100 Hazen Cloud Point (1% in water) 64-70 °C - Characteristics

Value Units Test Method / Conditions Active Content 90 % Clear Point 5 °C - Flash Point min. 100 °C - Foam Height according to Ross-Miles (after 5 min at 50°C in 0.05%) 20 mm - Foam Height according to Ross-Miles (immediately at 50°C in 0.05%) 110 mm - HLB 13.5 - - Pour Point 0 °C - Surface Tension (according to Du Noüy at 25°C in 0.1%) 30 mN/s DIN 53914 Viscosity (at 20°C) 100 mPa.s - Wetting Power (according to Draves, at 25°C, in 0.1%) 10 second - - Specifications

Value Units Test Method / Conditions pH (1% in water) 5 - 7 - - Water Content 9 - 11 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Surfactants in Paint

- The paint is from a surface chemistry point of view a very complex system. In order to make all these components form a stable colloidal suspension, a ‘compatibilizer’ is often required.

- The use of a surfactant as compatibilizer facilitates the use of having multiple sourcing of polymer emulsions, colorants / pigments and rheology modifiers, as the surfactants and surface chemistry properties of these components usually differ between producers.

- In the formulation of water borne paints, nonionic surfactants are often preferred. One main reason is that their action is less impacted by the presence of salts and other electrolytes, as are anionic surfactants.

- An Efficient Compatibilizer

Berol 185 is a nonionic, readily biodegradable surfactant that offers improved surface wetting, paint stability and color acceptance properties in water borne paints. It is a non label product, easy to handle and with good foam control.

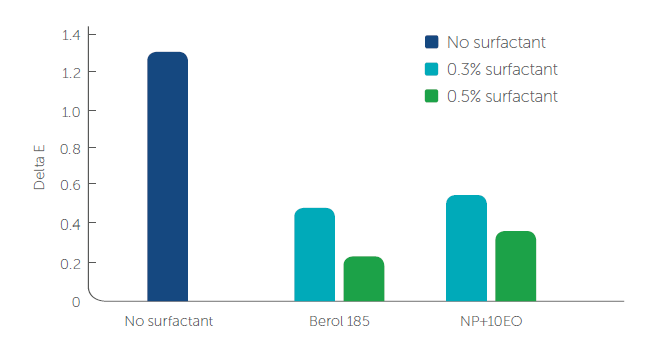

Color acceptance, colanyl black pigment

Results in color acceptance evaluation using Berol 185 in comparison with standard nonionic surfactant NP+10EO

Wetting performance

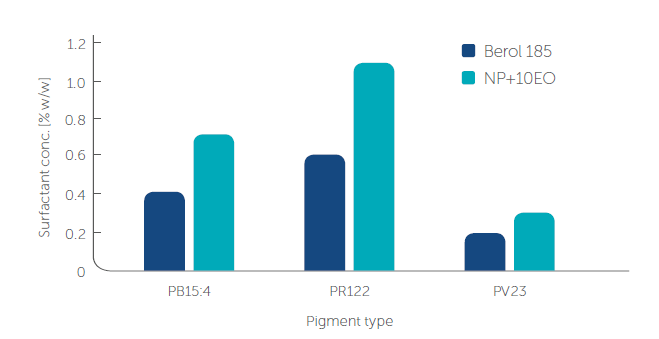

Berol 185 is a very efficient wetter and less dosage is needed to wet pigments compared to other wetting agents.

Amount of surfactant needed for wetting 2.5 wt% pigment in aqueous solution, comparison of Berol 185 with standard nonionic surfactant NP+10 EO

- Optimize your Formulation Performance

Good wetting agents are necessary to allow all componets to mix well and thereby improving the performance in the final paint.

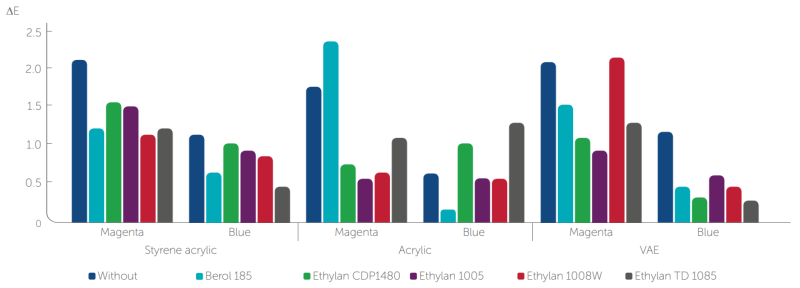

Color acceptance

0.25% addition

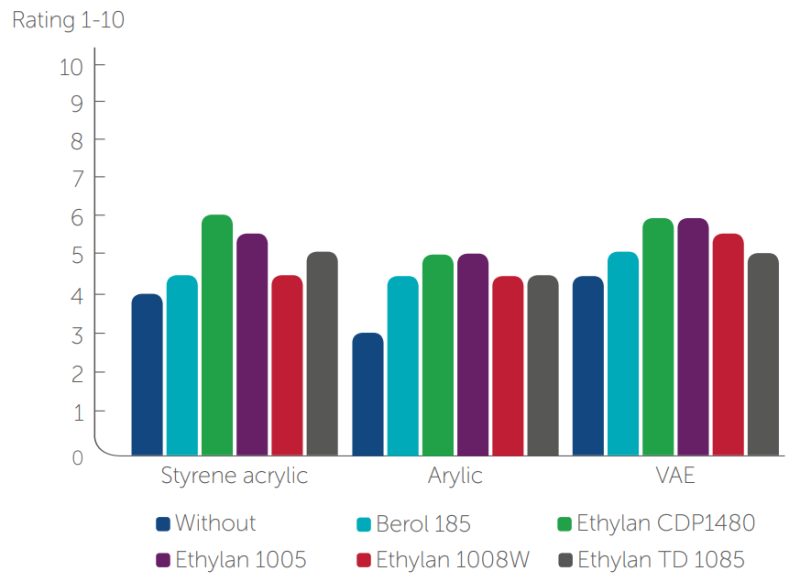

Leveling

0.25% addition

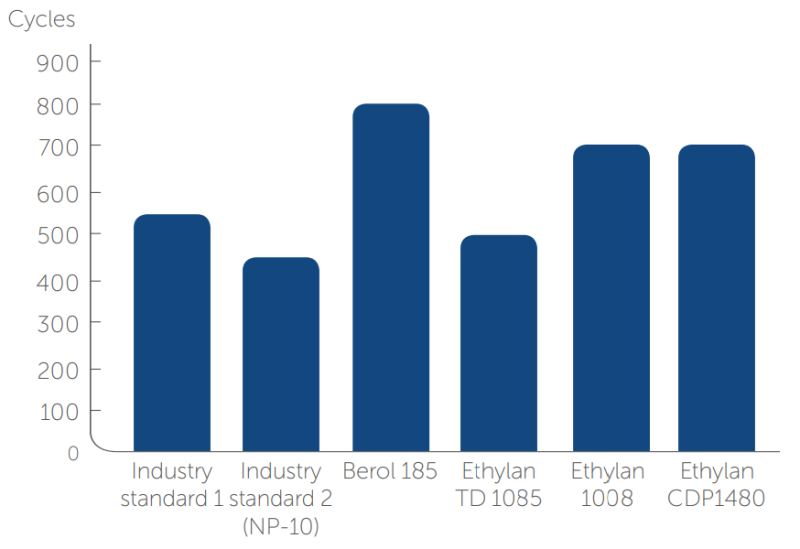

Scrub resistance

0.3% addition

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Conditions

Berol 175 should always be homogenized before use, unless the entire quantity is used.