Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Use Level

- 1-2%

Properties

- Physical Form

- Appearance

- Light yellow to amber liquid

- Soluble in

- Water

- Typical Properties

Value Units Test Method / Conditions pH (at 25°C) 7 - 8 Average Molecular Weight 3000 Solids Content 29 - 31 % - Notes

Typical Data are based on our own measurements or derived from the literature. They do not constitute part of the delivery specification

Technical Details & Test Data

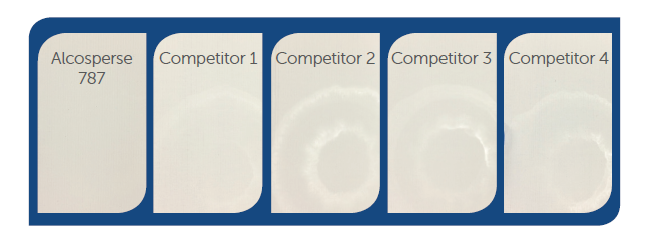

- Excellent Water Mark Resistance

Excellent water mark resistance and color acceptance Tests conducted by our scientists show that formulations containing Alcosperse 787 dispersing agent exhibit excellent watermark resistant performance when compared with other competitive dispersants.

Test method

Two layers of film with 120μm then 80μm were drawn down with applicator on 150mm × 70mm × 4~6mm cement plate. After six hours, when base coat dried, a top coat was applied. The cement plate was left at room temperature for 24 hours and then a 1ml water was dropped on the film. When the water dried completely, the water mark on the film was observed.

Alcosperse 787 is a novel hydrophobically modified acrylic copolymer dispersing agent developed to help formulators create innovative waterborne paints and coatings with excellent performance characteristics over competitive dispersants such as water mark resistance, alkaline and salt resistance, and other related hydrotropic effects.

Water mark resistance test results

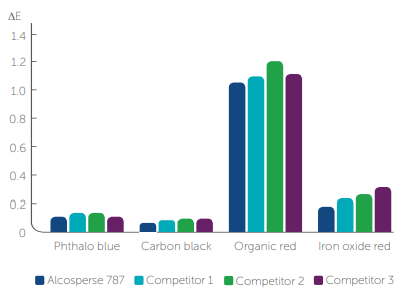

Color acceptance, 2% colorant and rub out

An effective way of evaluating the performance of the colorant is to check the color acceptance in various base paints. Good color acceptance (low dE00 number) is a sign of a well dispersed system.

- Test Data

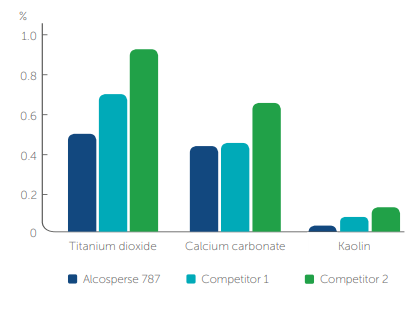

Dispersing efficiency

Test results demonstrate superior performance of Alcosperse 787 dispersing agent when compared to competitive dispersants.

Test method

Demand curve was used to evaluate the dispersing efficiency of dispersants. Procedure:

- Water and pigment or fillers were mixed to slurry

- Dispersants were added in 0.1-0.2g intervals to the slurry while stirring. Amount of dispersant and Brookfield viscosity of the slurry were recorded. The dispersant dosage at the lowest Brookfield viscosity is the minimum dosage.

Minimum dispersant demand data

Gloss and opacity performance

Test results demonstrate that formulations containing Alcosperse 787 dispersing agent have better or similar performance when compared with competitive products.

Gloss test results

Temperature (ambient)

Dispersant agent 20° 60° 85° Alcosperse 787 13 2.9 5.3 Competitor1 13 29 4.8 Competitor 2 1.3 2.7 4.9 Competitor 3 13 2.8 5.1 Competitor 4 13 2.7 42 Prepared film on a black and white paper card board by a 100μm bar applicator and tested by the gloss meter.

Opacity test

Dispersant agent Opacity Alcosperse 787 94.3 Competitor 1 94.28 Competitor 2 94.29 Competitor 3 93.31 Competitor 4 93.5 Prepared film on a black and white paper card board by a 100μm bar applicator and tested by the colorimeter

Packaging & Availability

- Regional Availability